PREVENTING EVAPORATION

OF SURFACE WATER STORAGE FACILITIES FOR LIQUID RADIOACTIVE WASTE

Kh. Dosmukhamedov Atyrau

State University, Atyrau, Republic of Kazakhstan

Abstract

In this article the author considers how to reduce

evaporation from water surface radioactive waste repository "Koshkar -

Ata" in Mangistau region of the Republic of Kazakhstan. This method is the

use of pontoons that are connected together in the form of rings and inside of

which are elastic inserts made of two layers of polyethylene film for storing

solar energy.

Key words: Radioactive wastes, water storage, evaporation, pontoons

Context

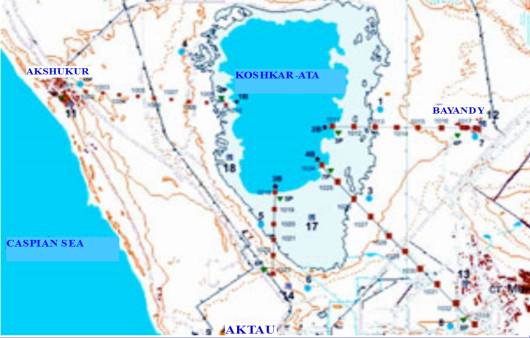

At

present, the overall level of contamination increased in the Republic of

Kazakhstan. For example, consider the storage of liquid solutions Koshkar-Ata,

located in the south-eastern part of the peninsula Mangishlak Mangistau region

of 5-6 km north-east of the city of Aktau and 8.7 km to the east coast of the

Caspian Sea (Picture 1).

Picture 1 - Location the storage of liquid solutions

Koshkar-Ata

Present

storage of liquid solutions area (77 sq km) has no analogues in the world. Total area of deposited

waste is 66 sq km area, bared beaches at this time is 39 sq km and the process of reduction of the aqueous phase

continues (Picture 2). The composition

placed on the storage of liquid waste comprises substances such as nitrates,

nitrites, ammonium, iron, phosphate, fluoride, strontium, zinc, copper,

chromium, molybdenum, manganese, lead, uranium, radium, thorium. The average

value of gamma radiation background atmospheric boundary layer was 0.12 mkrZv/h. Over the entire period of operation of the storage of

liquid solutions Koshkar-Ata it was stockpiled 51.8 million tons of radioactive

waste with a total activity of 11 200 Curie. Total storage in liquid solutions

placed 105 million tons of toxic and radioactive waste. Marked by elevated

concentrations of heavy metals in the soil ground settlements Akshukur,

Bayandy, Kyzyl-Tube station Mangistau and other areas located on the eastern

and western sides of the Koshkar-Ata. This occurs as a result of spraying

sections of beach storage of liquid solutions, as there is an increased drying

water's surface. In connection with the arrangement in the open countryside,

liquid solutions are storage evaporation energy of the sun and the spread of

harmful substances in the form of gas, dust and vapors. Therefore, necessary to

carry out remediation work, which in turn will not be able to fully solve the

environmental problem in the region. To prevent evaporation from the water

surface liquid waste and further provided the use of spray devices pontoon.

Picture 2 - The storage of

liquid solutions Koshkar-Ata

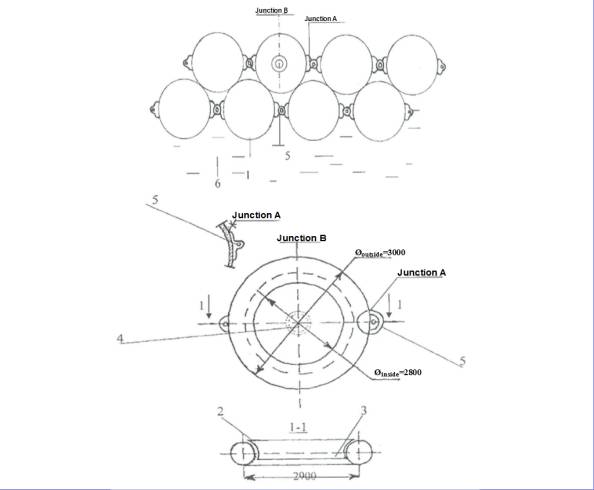

Solution proposed technical problem is achieved in that the aqueous

surface-coated with oil, is laid interconnected pontoons rubber rings in the

form of rings made of plastic pipes, which are located inside the elastic

inserts of two layers of plastic film for storage of solar energy.

Results

The resilient liner is made of rubber and tied up with the top of the

transparent film from the bottom - the dark. To eliminate the possibility of

spreading out in accordance with picture 3 (figure 2), they were fixed to each

other by means of rubber loops.

In the proposed method, the solar energy is used to melt the engine oil

on the water surface. This method can be applied in a dry hot climate Mangistau

region. Under the influence of solar energy, "heat sink" in the form

of water is heated and under the influence of the internal pressure of the

space under the film is filled with air (Figure 1, Figure 3), which is

impossible by close fitting to the surface. With the rise of pressure under the

film motor oil moistened through intensive steam flows in the oil, and the oil

in the pores of the steam is condensed and forces of the air. Oil, whose pores

are filled with water or closed so that the steam is not able to penetrate

inside, warmed primarily by conduction.

Picture 3 - Installation of pontoons to prevent evaporation from the

water surface liquid waste

1 - pontoons to form a ring of plastic pipes covered with transparent

film; 2 - clear polyethylene

film layer; 3 - black polyethylene

film backsheet; 4 - valve for draining

rain; 5 - rubber hinge; 6 - Oil "AC-8 . "

To

a saturated water vapor from the surrounding space can penetrate the pores of

the material and to condense therein, it must first penetrate the condensate

film on the exposed surface and then move the engine oil in the pores to some

of its depth, wherein the temperature inevitably lower than the saturation

temperature, the is below the transition temperature of the gaseous substance

into a liquid state. Moisture migrating into the pores under the influence of

engine oil gradient tends to compress air trapped in the pores of the engine

oil. In the pores creates an overpressure value which is determined by the

hydraulic resistance. As depth increases, the hydraulic resistance prevents its

exit to the environment increases, so the excess air pressure in the engine oil

increases from the surface into the engine oil. There is a pressure gradient,

which value is proportional to the flux density and moisture directed to the

opposite direction of fluid flow, i.e. from the bottom to the surface of the

engine oil. Under the influence of this gradient slowed the movement of

moisture and displaced part of the air contained in its pores.

The

pontoons are made in the form of a circle and covered with films surfacing

above the water surface will naturally keep the film at a distance of 10 cm,

which is sufficient to move warm air due to the pressure on the lower surface

of the film (temperature drop) in depth, towards the center of the circle to

lift out of the water.

Referring to picture 3 (figure 2) it allows the use of engine oil

performance AC-8 only between the pontoons at 0.25 dm3/m2

without fear of spreading out. The density of the film tension will act tensile

force of water on the inner radius of the circle.

To eliminate the accumulation of precipitation (rain, snow, etc.) in the

center of the circle is performed hole to drain rainfall (Picture 3, Figure 4).

For this purpose, the outer surfaces of the films are bonded rubber pads with

holes into which puts a rubber tube, weakened and flattened at the exit at the

bottom of the film to avoid backflow. Attenuation tube applies to the case of

increasing the pressure between the films, resulting in pressurization of the

top film (swelling).

Conclusions

The technology has a number of advantages and characteristics, namely:

• motor oil AC-8 is a waste not be disposed of having a very low

volatility, which allows you to not pollute the air above the pool MPC their

individual hydrocarbon ingredients, though they themselves liquid waste are

sources of pollution, and are cost-effective in relation to the costs for

transportation and application on water surface by dosing;

• use of used pontoons will reduce the use of motor oil, as well as

eliminate the use of electric heater that works by using electricity as the

heating surface of the engine oil comes from solar energy, which occurs when

the water is heated by the air generated by a polyethylene film with pop-over

pontoon the surface of the water;

• hot water can increase the leaching of valuable components from the

ore.

The proposed method to prevent evaporation would significantly slow down

the process of draining the coastal areas - beach areas and make a more dense

mineralized deposition ingredients of the aqueous phase.

References

1. информационный бюллетень

о состоянии окружающей среды Казахстанской

части Каспийского моря, Выпуск 1 (22) (1 квартал 2010 года).

2.

Айтбаева А., Бисекенов Т.Д., Есенаманова М.С. Радиоактивность почв, и

радиационное состояние хвостохранилища «Кошкар – Ата» в Мангистауской области.

3.

Есенаманова М.С. и другие. Способ предотвращения испарения

водных поверхностей. Предварительный патент №15812, 04.04.2005