V. Shybetskij, V.

Povodzinskij

National Technical

University of Ukraine

"Kyiv Polytechnic

Institute"

HYDRODYNAMICS MODELING OF ROLLER FERMENTER FOR CELL CULTURES

Cultivation

of cell cultures is used in biotechnology for the active pharmaceutical

ingredient, a biologically-active substances and in the production of vaccines.

Biotechnology of antiviral vaccines almost entirely focused on obtaining full

viral antigens using cell lines. In high-volume industrial production cells

become damaged by air bubbles and flows of medium.

Creation of

fermenters with variable intensity of the culture fluid flows is a critical

task of biotechnology.

Roller

fermenters often used for cell cultivation. But their design has a number of

disadvantages, the main one of which is the low specific capacity (due to the

small surface area of immobilization).

To solve

this problem, we propose a new fermenter, taking catalytic reactors by the

prototype.

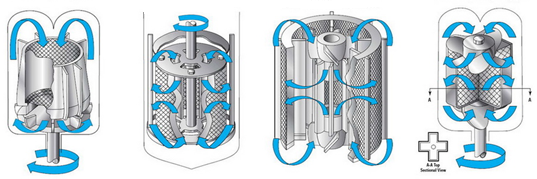

a b c d

Pic. 1. Catalic reactors

a – Berti reactor; b - Robinson-Mahoney reactor

with a movable basket;

c - Robinson-Mahoney reactor with a fixed

basket; d – Karberry reactor

The

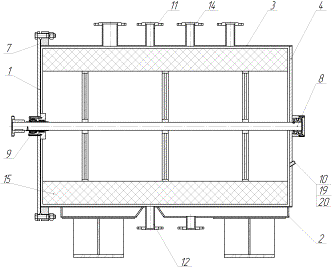

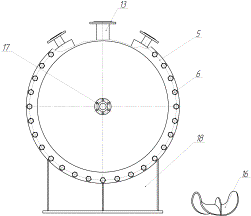

fermenter is as follows

Pic. 2. New Reactor

Its main elements are the body, cassette,

process fitting, heat shirt. The head with a large surface area is used for

immobilization.

The same conditions as in the Roller must be

created in the fermenter for optimal hydrodynamic situation. This is ensured by

the speed of rotation and the shear intension. For their determination we

should create a mathematical model.

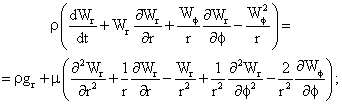

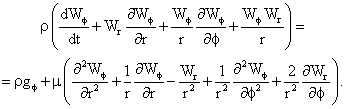

This model based on the Navier-Stokes equation,

which is:

(1)

(1)

(2)

(2)

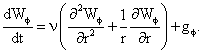

After all simplification we have the equation

in the canonical form:

(3)

(3)

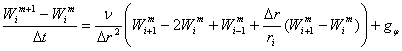

To solve the equation

we write the derivative as a difference of velocity values

, (4)

, (4)

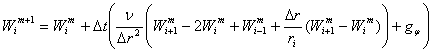

and rewrite the

equation in form:

. (5)

. (5)

The value of the shear intension is given by:

![]() . (6)

. (6)

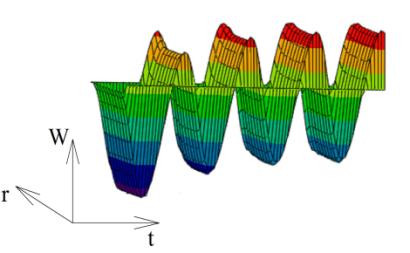

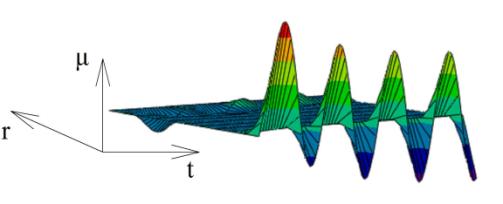

For numerical values the program was developed

in MathCad, and the graphs were drawn.

Pic. 3. Graph of speed

Pic. 4. Graph of shear intension

Upon receipt of the limiting values of shear

stress, it is possible to realize them on the new fermenter.