Химия и

химические технологии/ 5.Фундаментальные проблемы создания новых материалов и

технологий

Ph.d. Student, Sadeq Muneer Shawkat

National technical university

"Kharkov polytechnic institute", Ukraine

From waste animal fats and vegetable oils to

production biodiesel

Biodiesel is a renewable, biodegradable,

environmentally benign, energy efficient, substitution fuel which can fulfill

energy security needs without sacrificing engine’s operational performance.

Thus, it provides a feasible solution to the twin crises of fossil fuel

depletion and environmental degradation.

Any fatty acid source may be used to

prepare biodiesel. Thus, any animal or plant lipid should be a ready substrate

for the production of biodiesel. The use of edible vegetable oils and animal

fats for biodiesel production has recently been of great concern because they

compete with food materials - the food versus fuel dispute [1]. As shown in

below chart, the world production of feedstocks for biodiesel production can be

categorized as conventional vegetable oils, fats of animal origin.

Chart – World production

of oils and fats since 2007/2008 (Total 159.4 million tons)

There are concerns that biodiesel

feedstock may compete with food supply in the long-term [2]. Hence, the recent

focus is the use of non-edible fat and oil sources the feedstock for biodiesel

production meeting the international standards. Quality standards are

prerequisites for the commercial use of any fuel product. Since the

implementation of the European standard specification EN 14214 in 2004, a

standardized definition for biodiesel has been agreed as fatty acid methyl

esters (FAME) from any kind of feedstock, including waste fats and oils.

Biodiesel produced from wastes has the same possibilities to be utilized. The new

process technologies developed during the last years made it possible to

produce biodiesel from recycled frying oils comparable in quality to that of

virgin vegetable oil biodiesel with an added attractive advantage of being

lower in price [3, 4].

The term “waste fats and oils” refers to

materials which have been used in food production and which is no longer viable

for its intended use. Waste of animal fats and vegetable oils arises from many

different sources, including domestic, commercial and industrial. This type of

waste is a potentially problematic which requires to be properly managed. For

example the disposal of waste vegetable oil can be problematic, incorrectly,

down kitchen sinks, where it can quickly cause blockages of sewer pipes when

the oil solidifies. Properties of degraded used frying oil after it gets into

sewage system are conductive to corrosion of metal and concrete elements. It

also affects installations in waste water treatment plants. Thus, it adds to

the cost of treating effluent or pollutes waterways [5].

Consequently, efforts should be focused

on developing technologies capable of using this type of materials. Reusing of

these waste greases can not only reduce the burden of government in disposing

the waste, maintaining public sewers and treating the oily wastewater, but also

lower the production cost of biodiesel significantly. From a waste management

standpoint, producing biodiesel is environmentally beneficial, since it

provides a cleaner way for disposing these products; meanwhile, it can yield

valuable cuts in CO2 as well as significant tailpipe pollution gains. CO2 is the main contributor of global

warming and climate change through the enhanced [6].

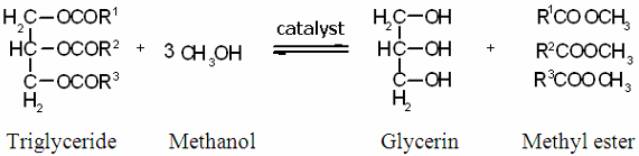

Regarding the production process of

biodiesel from the wastes it is using the transesterification technique as it

is the most economical process for treating virgin vegetable oils, also

includes reaction between the feedstock with short-chain alcohols (typically

methanol or ethanol), as well as catalysts are used to improve the reaction

rate and yield. Common catalysts for transesterification include sodium

hydroxide, potassium hydroxide, and sodium methoxide. The general

transesterification reaction equation is:

But there are some key parameters to identify the viability of the

low cost feedstock in biodiesel production (acid value and free fatty acids

(FFA) content, moisture content, viscosity and fatty acid profile). Waste

greases typically contain ≤ 35% FFAs, this is far beyond the level that

can be converted to biodiesel by using an alkaline catalyst. Some researchers

recommended using an alternative process for biodiesel production from low-

feedstock with a high content of FFA, via use of acid-catalyzed which have

claimed are more tolerant of free fatty acids [7]. Previous studies have

indicated that acid catalysts are too slow to be practical for converting

triglycerides to biodiesel.

However, acid catalysts appear to be quite effective at

converting FFAs to esters and this reaction is fast enough to be practical [8]. Thus, an

acid–catalyzed pre-treatment step to convert the FFAs to esters followed by an

alkali–catalyzed step to convert the triglycerides should provide an effective

and efficient method to convert high FFA feedstocks to achieve best results

with the high yield and purity of the produced biodiesel. The results of

scientific research and the novel technology proposed described a success of

using waste fats and oils as an important source for biodiesel production in

Ukraine and other countries.

References:

1. Pimentel, D.;

Marklein, A.; Toth, M. A.; Karpoff, M. N.; Paul,G. S.; McCormack, R.; Kyriazis,

J.; Krueger, T., (2009). Food versus biofuels: Environmental and economic

costs. Hum. Eco., 37 (1), 1-12 (13

pages).

2. Metzger, J.

O., (2009). Fats and oils as renewable feedstock for chemistry. Eur. J. Lipid

Sci. Tech., 111 (9), 865-876 (12 pages).

3. Canakci, M.,

(2007). The potential of restaurant waste lipids as biodiesel feedstocks. Bioresour.

Tech., 98 (1), 183-190 (8 pages).

4. Chhetri, A.

B.; Watts, K. C.; Islam, M. R., (2008). Waste cooking oil as an alternate

feedstock for biodiesel production. Energies, 1 (1), 3-18 (16 pages).

5. Szmigielski,

M.; Maniak, B.; Piekarski, W., (2008). Evaluation of chosen quality parameters

of used frying rape oil as fuel biocomponent. Int. Agrophys., 22 (4),

361-364 (4 pages).

6. Tschakert,

P.; Huber-Sannwald, E.; Ojima, D. S.; Raupach, M. R.; Schienke, E., (2008).

Holistic, adaptive management of the terrestrial carbon cycle at local and

regional scales. Glob. Environ. Change, 18 (1), 128–141 (14 pages).

7. Freedman, B.,

and E. H. Pryde. 1982. Fatty esters from vegetable oils for use as a diesel

fuel. In Vegetable Oils Fuels: Proc. of the Intl. Conf. on Plant and Vegetable

Oils as Fuels, 117–122. St. Joseph, Mich.: ASAE.

8. Canakci, M.;

Van Gerpen, J. Biodiesel production from oils and fats with high free fatty

acids. Trans. ASAE 2001, 44, 1429-1436.