Химия и химические технологии/ 5.Фундаментальные проблемы создания новых материалов и технологий

Ph.d.

Student, Sadeq Muneer Shawkat

National technical university "Kharkov polytechnic institute",

Ukraine

Technical aspects of biodiesel

production by using a heterogeneous catalyst

The

reactions for direct transformation of vegetable oils into ethyl esters and

glycerol have been known for more than a century. The reactions of interest

today, mainly those producing ethyl esters from rapeseed, soybean and sunflower

oils, have been studied and optimized in order to manufacture the high quality

diesel fuel known as biodiesel. With

over ten years of development and commercial use in

Europe, biodiesel has now

proved its value as a fuel for diesel engines [1-2]. The product is free of

sulfur and aromatics, and, as it is obtained from renewable sources, it reduces

the lifecycle of carbon dioxide emissions higher compared to conventional

diesel fuel. Moreover, recent European regulations in year 2005 have restricted

sulfur content in diesel fuel to no more than 50 ppm [3].

Several

commercial processes to produce fatty acid methyl esters from vegetable oils

have been developed and are available today. These processes consume basic

catalysts such as caustic soda or sodium methylate which form unrecyclable

waste products. This work provides a general description of a new process using

a heterogeneous catalytic system.

Biodiesel

production principles and processes

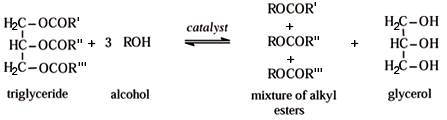

The

transesterification of triglycerides to ethyl esters with ethanol is a balanced

and catalyzed reaction as illustrated in Figure 1. An excess of ethanol is

required to obtain a high degree of conversion. Rapeseed and soybean oils are among the main vegetable oil candidates

for biodiesel uses.

Figure 1. Overall

reactions for vegetable oil alcoholysis.

The

conventional catalysts in natural oil transesterification processes are

selected among bases such as alkaline hydroxides [4]. However,

transesterification could also be performed using acid catalysts, such as

sulfuric, or using metallic base catalysts such as oxides of calcium,

magnesium, or zinc. All these catalysts act as homogeneous catalysts and need

to be removed from the products after the ethanolysis step.

Heterogeneous

catalyzed

To

avoid catalyst removal operations and soap formation, much effort has been

expended on the search for solid acid or basic catalysts that could be used in

a heterogeneous catalyzed process [5-6]. Some solid metal oxides such as those

of calcium, magnesium, and zinc are known catalysts but they actually act

according to a homogeneous mechanism and end up as metal soaps or metal

glycerates. This work a new continuous

process is described, where the transesterfication reaction is promoted by a

completely heterogeneous catalyst. This catalyst consists of a mixed oxide of

zinc and aluminum which promotes the transesterification reaction without

catalyst loss.

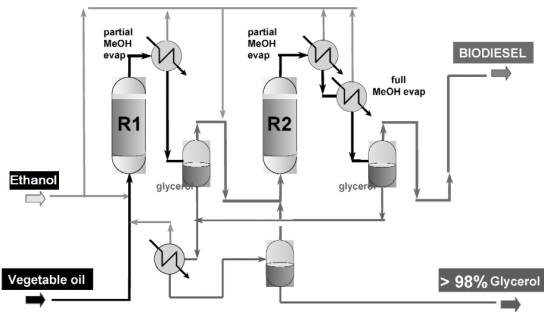

The

reaction is performed at a higher temperature than homogeneous catalysis

processes, with an excess of ethanol. This excess is removed by vaporization

and recycled to the process with fresh ethanol. The desired chemical conversion

is reached with two successive stages of reaction and glycerol separation to

displace the equilibrium reaction. The flow sheet for this process appears in

Figure 2.

Figure 2. General

scheme for a continuous heterogeneous catalyzed process.

The

catalyst section includes two fixed bed reactors that are fed by oil and

ethanol at agiven ratio. Excess ethanol is removed after each of the two reactors

by a partial flash. Esters and glycerol are then separated in a settler.

Glycerol phases are joined and the last traces of ethanol are removed by

vaporization. Biodiesel is recovered after final recovery of ethanol by

vaporization under vacuum and then purified to remove the last traces of

glycerol. In this heterogeneous

process, the catalyst is very stable with no metal leaching. There is no

formation of either glycerate salts or metal soaps which affords the following

advantages: no neutralization step is required, there is no introduction of

water, and there is no salt formation; these accounts for exceptional glycerol

purity. In addition, there is no waste production of low-value fatty

acids.

The

purity of ethyl esters exceeds 98% with yields close to 100% of the

theoretical. Glycerol treatment is much easier than in homogeneous catalyzed

processes. A simple elimination of ethanol by vaporization suffices and no

chemicals are required. The glycerol produced is neutral, clear and exempt from

any salt, with purities above 98%. This valuable product could be used in many

chemical applications without further treatment. If required, pharmaceutical

grade can easily be reached.

The process feeds are limited to vegetable oils and ethanol and the only

products are biodiesel and a high-purity glycerol that is free of water and

salt. With all its features, the process can be considered as a green process.

Experiments on ethanolysis with acid-containing vegetable oils have also been

conducted with no special acid removal treatment of the raw material.

ethanolysis of a blend of 5% oleic acid in rapeseed oil leads to an ester product composition compatible with

biodiesel requirements. In that case, esterification and transesterification

reactions occur simultaneously.

References:

1. Canakci, M.,

(2007). The potential of restaurant waste lipids as biodiesel feedstocks.

Bioresour. Tech., 98 (1), 183-190 (8

pages).

2.

Biodiesel - A Success Story, Report

of the International Energy Agency, February 2002.

3.

Montagne, X., 2nd European Motor Biofuels Forum, Graz,

September 1996.

4. Kreutzer, U., J. Am. Oil.

Chem. Soc., 1984, 61 , pp.343.

5. Stern, R.; Hillion, G.;

Rouxel, J. J.; Leporq, S. US Patent

5,908,946 (1999)

6. Gelbard, G.; Brès, O.;

Vielfaure-Joly, F. J. Am. Oil. Chem.

Soc.,1995, 72, pp1.