The method of reconstruction of the drive mechanism

for lifting floating crane bucket based on an assessment of durability metal

floating crane.

A.S. Yablokov

Key words: cycle

fatigue experiment, damage, material parameters, the torque converter, impeller,

turbine, reactor wheel, grab

The article discusses the

problem of assessing the durability of metal structures of the engine room of

the floating crane. Examined the effects of the phenomenon of

"suction" grab for floating cranes involved in subsea production. The

solution of the problem - including in the drive mechanism for lifting the

torque converter, as well as the requirements to specifications and design for

such a converter.

Contacts: alex-vodnik@mail.ru

Introduction.

When subsea floating cranes as a

lifting body uses grapple. Hoist and scoop grab the floating crane is not

different from the hoist gantry crane, which when overloaded bulk materials as

well as the lifting body uses grapple. However, when operating in the

water-saturated material of the grapple under water when scooping and lifting

raises additional hydrostatic forces "suction" filtering hydrostatics

and viscous flow of the material in the grapple, which depend on the speed of separation

and scooping material grapple, which leads to stresses in the hoisting ropes

and metal crane. This effect, which occurs in a short period of time, may

exceed the 50% allowable load on the crane and a "peak" [1].

Currently 90% of floating cranes have a lifespan of 15 years or more, which makes their use problematic in underwater mining, as their metal worn and are not designed for such loads.

1. Evaluation of the durability of metal floating crane CPL 5-30.

To assess the durability

of metal floating crane CPL 5-30, was calculated metal frame floating crane

engine room CPL 5-30, Head. №2040, made in 1974 by the "ship" Bor. To

date, the floating crane was committed 902,467 cycles and handled 2,256,168

tonnes (according to the organization of the operator). Material metal crane

St3kp. Determination of stress-strain state of a floating crane performed

depending on the operating conditions of the crane:

1. For the first case,

the calculation was chosen nominal mode of operation of the crane, the

corresponding maximum permissible load capacity - 5 tons, the marginal wind

load working condition - wind speed of 15 m / s, the maximum inertia load and a

maximum roll pontoon - 30.

2. For the second case

selected peak operation of the crane, this mode occurs when using the grapple

in water-saturated material under water, when scooping and lifting raises

additional hydrostatic forces, "suction", filtration, hydrostatic and

viscous flow of the material, depending on the speed scoop up material and

separation of the grapple, which leads to stress the rope hoist and crane

metal. This effect occurs in a short period of time and may exceed 30%

allowable load on the crane and a "peak".

Lifting speed of cargo:

m / s, the maximum weight of the load lifted kN. For a general idea of the

nature of deformation of the frame and identify the location of the nodes that

are critical in terms of durability, the first stage was carried out by elastic analysis account code [2].

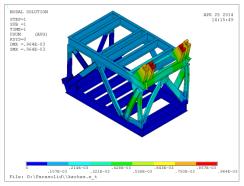

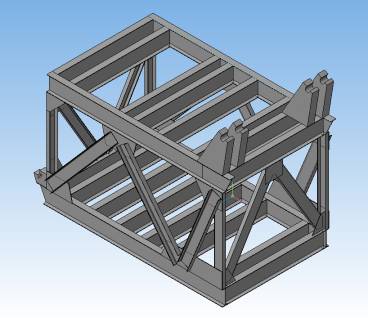

Fig. 1. -

The model of the engine room carcass floating crane.

Physical and mechanical characteristics

of St3 were adopted as follows: Young's modulus of elasticity ![]() mPa, Poisson's ratio ν=0,28, yield point σТ = 230 mPa, density ρ=7820 kg/m3. The frame

was modeled in full size in compliance with specified characteristics and

geometry. Each compound was replaced by a rigid - welded. Modeling supports the

frame also been conducted, but in places bearing frame on the turntable imposed

boundary conditions precluding movement of nodes in all directions and turn

them into these nodes. Based assortments used profiles idealization carcass

structure into finite elements was carried out using 8, 10, 20 - the final

nodal elements are symmetric in cross section.

mPa, Poisson's ratio ν=0,28, yield point σТ = 230 mPa, density ρ=7820 kg/m3. The frame

was modeled in full size in compliance with specified characteristics and

geometry. Each compound was replaced by a rigid - welded. Modeling supports the

frame also been conducted, but in places bearing frame on the turntable imposed

boundary conditions precluding movement of nodes in all directions and turn

them into these nodes. Based assortments used profiles idealization carcass

structure into finite elements was carried out using 8, 10, 20 - the final

nodal elements are symmetric in cross section.

The calculation results

are shown in Table 1, which shows the maximum values of the stresses and

strains in the elements of metal carcass floating crane CPL 5-30.

Table 1 - Results of calculation.

|

№ |

Stress |

mPa |

Strans |

m |

|

1 |

Σ |

149 |

e |

0.964x10-3 |

|

2 |

σX |

32,5 |

eX |

0.8x10-3 |

|

3 |

σY |

52,6 |

eY |

0.426x10-4 |

|

4 |

σZ |

65,0 |

eZ |

0.484x10-3 |

|

5 |

σXY |

36,6 |

eXY |

0.227 x10-3 |

|

6 |

σYZ |

46,7 |

eYZ |

0.29 x10-3 |

|

7 |

σXZ |

18,0 |

eXZ |

0.112 x10-3 |

Results of calculation of the

maximum deformations and stresses in the critical elements of the framework

presented in Figure 2. It is seen that the stress state is triaxial

(volumetric) character.

|

|

|

|

a) the equivalent stresses |

b) the total deformation |

|

Fig. 2 - The results of the calculation. |

|

From the analysis of

solutions of the problem (see Table 1) shows that the stress level does not

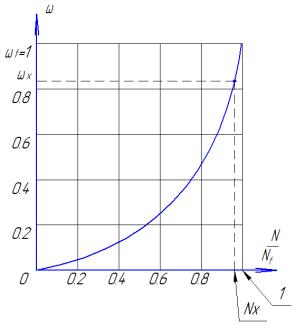

exceed the yield strength. Figure 3 shows the curve of damage ![]() relative to the number of

loading cycles

relative to the number of

loading cycles ![]() , where Nf – number of cycles to

macrocrack formation. Analyzing the results of the maximum strain and stress

can be concluded that the amount of accumulated damage is in the danger zone

(close to the "critical" value (

, where Nf – number of cycles to

macrocrack formation. Analyzing the results of the maximum strain and stress

can be concluded that the amount of accumulated damage is in the danger zone

(close to the "critical" value (![]() ).

).

The

evaluation of durability of the floating crane CPL 5-30 Head. №2040 concluded

that the development of the resource metal frame of the engine room (residual

life is within the error calculation) and is necessary to overhaul with

replacement metal bearing loaded elements, or the reconstruction of the crane.

Fig. - 3 - Curve

damage.

2. A method for increasing the

reliability of steel structures and the drive mechanism for lifting floating

crane clamshell.

The

torque converter allows you to automatically adjust the speed of lifting and

closing the grab by creating a feedback between the load on the ropes and speed

scooping and lifting the grab. They allow you to smoothly change the gear ratio

from the motor to the gearbox by 3.5 times in the direction of increasing and

correspondingly increasing the torque on the shaft of the gearbox, which will

overcome the effect of "peak" loads. Additionally, a means, which

prevents the actuator from any overload, since the torque transmission therein

through the liquid, rather than through a rigid kinematic linkage.

Analysis of the properties and characteristics of the

existing torque converters [3, 4] allows us to formulate requirements for them

to be installed in the mechanism of lifting floating crane:

1.Torque converter possessing high speed, must have the appropriate

damping properties to avoid the effect of his work on the high-frequency

oscillations in the hoisting ropes.

2. Torque

converter must ensure operation of the motor drive in optimal conditions, will

not enter when all the input power is spent on "myatie" fluid. Such

requirements are met completely "opaque" torque converters [3, 5, 6],

but the creation of torque converters of this type is problematic [6, 8], so it

is advisable to apply torque converters with a low degree of "transparency"

in the range of 1.0 ... 1.1 in the main working area.

Transparency

- property impeller change the amount of torque when changing the gear ratio

torque converter. If the change gear ratio of torque on the pump wheel remains

constant, the torque converter is called the "opaque."

3. Torque

converter must convert the torque in the drive to the full range of workloads.

Floating crane for maximum transformation ratio must be between 1.4 ... 1.6

[1]. Within the specified value ratio and maximum accepted level of

transparency appropriate to use a single-stage torque converter having its

greatest simplicity of design [4, 6, 7].

4. Torque

converter should have a locking device in order to provide the drive with a

constant low speed, i.e. have a freewheel.

5.

For creating a drive mechanism for lifting torque converter is necessary to

combine original characteristics of the induction motor and the torque

converter, which is carried out by combining the rated torque of the motor with

the zone of maximum efficiency torque converter. In this case, the converter

convert properties used in all operating modes of the drive with the

implementation of positive qualities, in relation to underwater mining.

On

the basis of the formulated requirements necessary to select the following

parameters converter mechanism for lifting floating crane.

Optimum

is a single-stage torque converter with a comparatively simple design and the

cheapest to produce.

The

main requirement to the torque converter - high efficiency in the working area.

This requirement may be more fully realized in integrated torque convertors (s

centripetal turbine and the symmetrical arrangement of the pump and turbine

wheel . Moreover, in a centripetal turbine torque converter when installed in

the reactor wheels clutches realized efficient operation of the fluid coupling

mode. The observed property is due to the fact that the output torque

converters of this type of hydraulic fluid from the pump wheel is located on a

larger diameter circle its circulation.

This

analysis of the performance requirements and the design of the drive torque

converters for floating cranes lifting mechanism, the relevant conditions and

loads, suggests that they correspond to the most complex type torque converter

with a centripetal turbine.

At

the hoist drive, developed by the authors at the Department of handling

machines Volga State Academy of Water Transport, received a patent for utility

model №91999, and work is underway to further development and implementation of

the actuator.

References.

1 Nikitaev, IV Ship power grab

installations for the extraction of ore materials on the continental shelf / IV

Nikitaev - Nizhniy Novgorod: VSAWT, 2000. - 26 p.

2 CAD / CAE system APM

WinMachine

3 Anokhin, VI The use of

high-speed torque converters on crawler tractors / VI Anokhin - M .: Mechanical

Engineering, 1972. - 304 p.

4 Anokhin, VI On the choice of

the basic parameters of the converter for hydromechanical transmission speed

tracked agricultural tractor / VI Anokhin, [et al.]. // Tractors and

agricultural machinery. - 1985. - №10. - S. 11 - 15.

5 Kochkarev, AJ Hydrodynamic

transmission / AY Kochkarev - L .: Mechanical Engineering, 1971. - 336 p.

6 Narbut, AN Torque converter

/ AN Narbut - M .: Mechanical Engineering, 1966. - 218 p.

7 Anisimov, VB Torque

converters for building and road machines / VB Anisimov - M .: Stroyizdat,

1967. - 42 p.

8 panties, SM Automotive

torque converters / SM Pants - M .: Mechanical Engineering, 1977. - 211 p.