Technical science/2. Mechanics

Dr. Sc. Techn., professor Gots A. N.

Vladimir state University of a name Alexander

Grigorievich and Nikolai Grigorievich Stoletovs, Russia

New schematized diagram of limit cycles under the action of normal

stresses

Calculation

of factors of safety of machine parts under the action of normal stresses in

the case of uniaxial stress state and the asymmetric cycle of loading with

amplitude σa and mean stress σm is performed on the basis of dependency S. W.

Serensen, and R. S. Kinasoshvily [1]:

, (1)

, (1)

where Kσ is the effective stress concentration factor; εσ scale

factor; βσ

coefficient of the surface layer; ψσ

coefficient of influence of cycle asymmetry or coefficient, which characterizes

the sensitivity of the material to the asymmetry of the cycle [2] .

The

maximum amplitude of the stresses σra for laboratory sample

with asymmetric cycle of loading can be expressed by the equation, well the

corresponding experimental data in the range of variation of the coefficient of

asymmetry ![]()

![]() , (2)

, (2)

where σrm is the current value of the limiting medium stress of

cycle.

In

computational practice, often use a schematized diagram of the limiting

amplitudes Serensen-Kinasoshvily in which the coefficient ψσ equal

![]() , (3)

, (3)

where σ0 is the

fatigue limit of laboratory samples in a pulsating cycle.

Because

the value of σ0 in the

reference literature is not given, it is recommended to define her by the approximate

formulas [3]. For steels in bending and tension-compression ![]() . Upper limits refer to mild steels. It is easy to

notice that with this choice of σ0, after

substitution in (3) the coefficients ψσ will be constant, independent of the

mechanical characteristics of the material.

. Upper limits refer to mild steels. It is easy to

notice that with this choice of σ0, after

substitution in (3) the coefficients ψσ will be constant, independent of the

mechanical characteristics of the material.

In

[1] for steels calculation ψσ it is

proposed that the formula

![]() , (4)

, (4)

where

σv is the tensile

strength, MPa.

From

(4) it follows that ψσ varies

from 0.1 at σv = 400

MPa, while σv = 1500

MPa to 0.32.

The

value of ψσ can be

determined by constructing the author's proposed new schematized diagram of

limit cycles sra = f(srm). To do

this, use for limit cycles linear dependence Goodman [4]

![]() , (5)

, (5)

and parabolic Gerbera [4]

![]() . (6)

. (6)

|

|

|

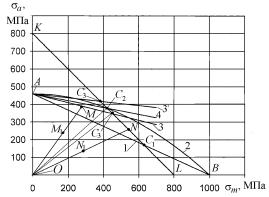

Fig. 1. Chart of

the limiting amplitudes for steel 40XH: 1 direct of Goodman; 2 Gerber

parabola; 3 marginal direct Serensen-Kinasoshvily(s0 = 1,6s-1); 4 proposed direct s0 = 1,8s-1; 3 the same when s0 = 1,6s-1 4 proposed direct schematized diagram |

In

Fig.1 for steel 40XH (with the characteristics of mechanical strength in MPa:

tensile strength σv =1000; yield

strength σ0,2=800;

endurance limit of a symmetric cycle σ-1=460) the diagrams of the limiting amplitudes

using the dependences (5) direct 1 and (6) curve 2.

For

parts made from plastic materials according to (5) and (6) are valid as the

threat to them is sra = f(srm) only on a portion

of the chart not only fatigue, but also

the transition for the yield strength, which leads to residual deformations

that distort the shape and dimensions of the part.

Therefore, the maximum stress cycles must be less not

only endurance limit, and yield strength smax = sa + sm < s0,2.

In order to exclude from the chart sra = f(srm) the area

where the limiting maximum stress σrmax=sra + srm > s0,2, take the

straight line KL, which cuts off on

the cuts the coordinate OL and OK is equal to the yield strength (steel

40XH s0,2 = 800

MPa, Fig. 1). The equation of a line KL

is:

![]() . (7)

. (7)

Thus, for the parts made of plastic materials chart

limit amplitude in the coordinate axes sm-sa is

limited by the line 1 and the parabola 2 (Fig. 1) until they intersect at the

points C1 and C2 with direct KL, and more direct C1L or C2L. The coordinates of the points of the

broken lines AC1L or AC2L give limit values and depending on the

selected function sra = f(srm).

Replace plot charts Goodman and Gerber schematized

diagrams. In Fig.1 by equation (2) with (3) built direct limit

Serensen-Kinasoshvily 3, assuming ψσ= 0,11)

and 3, ψσ= 0.25 to

crossing them with direct KL at the

points and respectively. Note that the direct limit ![]() (if taken

(if taken ![]() ) will be above the Gerber parabola, which contradicts

the results of studies P. Forrest [4].

) will be above the Gerber parabola, which contradicts

the results of studies P. Forrest [4].

For steel 40XH, using (4), find the value of ψσ= 0,22.

Limit direct, built according to (4), in this case almost coincides with the

straight 3 (Fig. 1).

Build a schematized diagram using three points σ0,2,

σ-1 and the

coordinates of the point of intersection C2

(![]() ) Gerber parabola with a straight KL. Combine in a system of dependency (7) and (8), after the

decision of who will receive the coordinates of the point C2 (

) Gerber parabola with a straight KL. Combine in a system of dependency (7) and (8), after the

decision of who will receive the coordinates of the point C2 (![]() ):

):

(8)

(8)

. (9)

. (9)

Connecting points A

and C2(![]() ), get a new schematized diagram OAC2L (Fig. 1)

in which the tangent of the slope of the straight AC2 to x-axis , considering the influence ys is

numerically equal to the coefficient of

medium stress (constant component of the cycle) at the limit of endurance:

), get a new schematized diagram OAC2L (Fig. 1)

in which the tangent of the slope of the straight AC2 to x-axis , considering the influence ys is

numerically equal to the coefficient of

medium stress (constant component of the cycle) at the limit of endurance:

. (10)

. (10)

When

calculating the value ys according

to the formula (10) are used, only those characteristics of mechanical

strength, which are listed in the reference literature.

Formulas (8) and (9) allow us to determine what type

of destruction is dangerous for a known working medium sm and the

amplitude sa stresses.

If during the calculation details sm/ sa < srm /sra , the duty

cycle of stresses is in the field OAC2

(Fig. 1) and calculate the factor of safety should be based on (1). If sm/ sa > srm /sra, the calculation is based on [1-3]:

(11)

(11)

The values of the coefficients ψσ and

relations limit srm /sra, can be defined by the formulas (9), (10) and (11) for steels, if known

mechanical characteristics of the materials.

In our proposed schematized diagram direct limit AC2 is located between the

parabola 2 and 1 direct, i.e., it satisfies the experimental data for ductile

metals [4, 5].

LITERATURE

1. Kogaev V. P., Makhutov N. A., Gusenkov A. P.

Calculations of machine parts and structures for strength and durability:

Handbook M.: Mashinostroenie, 1985. 224 p.

2. Birger I. A., Shorr B. F., Iosilevich G. B.

Calculation of the strength of machine parts. Handbook. M.: Mashinostroenie,

1993. 640 p.

3. Handbook on strength of materials // M. N.

Rudizin, P. Y. Artemov, M. I. Lyuboshitz.; Under the editorship of M. N.

Radizina. Minsk: Vysheishaya school, 1970. - 630 p.

4. Forrest P. Fatigue of metals. Translation

from English. Under the editorship of S. V. Sorensen. M.: Mashinostroenie,

1968. 352 p.

5. Collins J. Damage of materials in

structures. Analysis, prediction, prevention: Trans. from engl. M.: Mir,

1984. 624 p.

6. Gots A. N. The calculations of the strength

of engine parts with voltages, variable in time/A. N. Gots 3-e Izd. M.:

FORUM; infra-m, 2013 208 p.http://www.translate.ru/%28%F2%E0%EChttp://www.translate.ru/%28%F2%E0%EC