Master student Terekhova A.A.,

Ph.D.Dyakov I.A.

Tambov State Technical University, Russia

The use of carbon nanotubes in electrical engineering

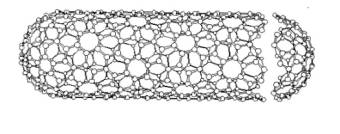

Carbon nanotube is a long cylindrical graphite

rolled strips with thickness up to several tens of nanometers and length up to

several centimeters with a carbon frame structure. Under this structure include

larger molecules are connected only to carbon atoms. At the ends of nanotubes

are usually formed by hemispherical heads (Fig.1).

Carbon nanotubes come in different shapes and

sizes – straight and curved, single layer and multilayer. Despite the fact that

at first glance they seem very fragile, actually they are quite durable

material that has been proven by many studies. It was found that carbon

nanotubes are characterized by such properties as tensile and bending, i.e.

under the influence of various mechanical loads the elements do not break and

are broken, and this suggests that they can adapt to different voltages.

Fig. 1 Idealized model of single-layer

carbon nanotubes

Due to characteristics such as bending strength

and conductivity of carbon nanotubes used in many fields: as additives to

polymers as absorber of electromagnetic waves, in the manufacture of various

sensors and capacitors, to transform electricity, in the production of

composites with the aim of strengthening their structure and properties.

Repeated experiments conducted by different

scholars, show that carbon nanotubes are the most rugged and tough of all known

materials - a material with a record

high values of ultimate tensile strength (~60

GPA) and young's modulus (≈ 1 TPA). It is connected with perfection of

structure and the strong sp2 chemical bond between the carbon atoms that

comprise the nanotube.

Nanotubes are also good heat conductors along

the tube, showing properties, so-called, unimpeded conductivity or

superconductivity. However, across the axis of the nanotubes have high thermal

insulation properties.

An interesting feature of carbon nanotubes is

that they can be metallic or semiconducting depending on their diameter and

chirality. As a result of the synthesis is usually a mixture of tubes, two

thirds of which have semiconducting properties, and one third metallic.

Metal tubes usually have a chair structure

(Fig.2A) and semiconductor zigzag (Fig.2B) and spiral (Fig. 2B).

Metallic and semiconducting carbon nanotubes

differing conductivity metal can conduct current at a temperature of 0 ° C, and

the semiconductor only at elevated temperatures.

Widespread use of carbon nanotubes in

electrical engineering possible due to the fact that they can transmit currents

with a density higher than the most conductive metals, such as copper. So a

single layer of nanotubes pass currents of density up to 109 A/cm2, and the

multilayer is up to 100 µa/cm2, and copper at such values of current density

melts.In addition, when the resistance is comparable to copper, and carbon

nanotubes is four times easier.

Carbon nanotubes outperform copper by such

indicators as the coefficient of thermal conductivity along the axis. For

copper it is equal to 400W/(m×K), for nanotubes 500 -5500 W/(m×K).

Another advantage of nanotubes is due to cold

emission of electrons, an along the tube axis of the electric field. The field

strength in the vicinity of the top part hundreds of times higher than the one

that exists in the volume, which leads to anomalously high values of emission

current at a relatively low external voltage and allows the use of nanotube

macroscopic system as a cold emission cathodes. The degree of emission of

carbon nanotubes can be used in the manufacture of flat panel displays and touch

control panels.

|

б) |

Fig.2 Types of carbon nanotubes:

a – chair structure; b – zigzag structure; с – helical structure

The application of carbon nanotubes in the

production of various electrical devices is one of the most promising

directions of work of scientists around the world. Due to the properties of the

nanotubes described above, their use in the production of, for example, cables

and wires is quite beneficial. Due to its lightness and high conductivity

cable, manufactured with the use of carbon nanotubes will significantly surpass

its copper predecessor, which makes its production more profitable.

The authors propose to use carbon nanotubes in

the manufacture of various parts of electrical machines. For example, the brush

for electric machines that are special conductive parts of the current

collection devices that provide a sliding contact between the stationary and

rotating parts of the machine and serve to supply or drain current, when you

add in the production of carbon nanotubes in them will last longer than usual.

Or, for example, nanomodification coating of housings of electric motors will

improve their heat-transfer properties. Such measures will allow to increase

the service life of electric motors, which will significantly reduce costs in

their operation.

Currently, due to their properties carbon

nanotubes are one of the most promising materials used in many industries.

Despite their shortcomings, such as toxicity, the use of nanotubes in

electrical engineering due to the need to create a new material the properties

of which will be an opportunity to reduce the cost of production and operation

of electrical equipment.