Agriculture 4. Technologies of storage and

processing of agricultural products

Assoc.

Prof. V. Yu. Ovsyannikov, postgraduate

student Ya.I. Kondrateva,

student N.I. Bostynets student A.N.

Denezhnaja

Voronezh State University of

Engineering Technologies, Russia

Apparatus for freezing products in

metal molds, immersed in the liquid refrigerant

Different processes of food technology are used for

the clarification, the stabilization and the concentration of juices,

nonalcoholic beverages and faults. Refrigerators processes especially expedient

to use in cases when divided mixture contains not the stable and easily

destructive substances. Similar are most frequently liquid food media, for

example, juices, extracts, protein solutions and many others.

Development of the processes of separating freezing

gives the possibility to create fundamentally new flow charts and equipment for

the complex processing of the vegetable raw material, to decrease environmental

pollution due to the application of wastrels technologies, and to also obtain

foodstuffs with the new functional properties and the high food nourishment

value.

Refrigerators processes in the technology of the

production of fruit juices at present are used in essence for their

clarification and concentration. The freshly-pulled fruit juice is the complex

colloidal system, formed by the smallest particles of plant tissue, not

dissolved in the water. Besides the particles of the fruit cloth and pulp, the

juices contain yeast cells, ballast admixtures, which are the reason for the

formation of dimness and sediments.

Such particles in the process of storing the juices

aggregate and fall out into the sediment. Stability to heterogeneous system gives

the stabilizers, which form on the area of the particle ionic or molecular

adsorptive layer. The presence of similar electric charge, and also hydrated

shells prevents aggregation of particles, which hampers the process of

independently clarified. Furthermore, in the juices are contained the

high-molecular connections of the complex chemical structure, for example,

pectin and protein, polyphenol and coloring, which also participate in the

formation of colloids. Thus as the interphase interface in this case it is

absent, then the molecular disperse systems, formed by these biopolymers, are

characterized by the increased stability and reversibility.

Clarification of fruit, fortified juices and wines is

associated not only with the removal of suspended solids, but also the partial

destruction of the colloidal system, instability of temperature variations and

long-term storage. Colloidal system must be destroyed only to the extent to

provide fast sedimentation of suspended particles, good filterability juice and

sufficient stability of the filtered juice when further storage.

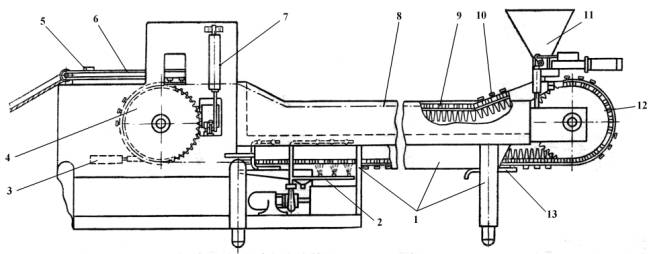

To this end, developed an apparatus for freezing

liquid and semi-liquid foods (vegetables, fruit juices, tomato paste, fruit

puree) in the forms immersed in a bath of coolant (see the figure) consists of

a welded frame, drive and tension Stars, drive unit, freight (working) conveyor

forms, bath with chilled water, filling, discharge conveyor and the cleaning

device.

Welded frame is equipped with six adjustable feet.

The drive and tension sprockets are mounted on a

common shaft. One drive sprocket circumferentially reinforced special fingers.

The drive unit consists of a hydraulic cylinder, the

piston rod is moved in the guides, and the oscillating pusher.

When the working stroke of the push rod abuts one of

the fingers located on the side surface of the drive sprocket. After a star

turn by one step.

Plate Exalt cargo conveyor move metal shapes and trims

are designed for excavation of frozen blocks of forms.

When you turn the drive sprocket one step form stops

underneath the filling. Strips at the time of filling out forms product must be

in it. Completed forms, together with the product bar to empty forms are moving

forward and are immersed in a bath of cold coolant, where the product is

frozen.

Fig. 1 Apparatus for freezing products in metal molds, immersed in the

liquid refrigerant:

1 - frame unit; 2 - washing device; 3 - driving device; 4 - driving

asterisks;

5 - freezable block; 6 - unloading conveyor; 7 -podemnik bath thawing; 8

- bath with

coolant; 9 - commercial (business) conveyor forms; 10 - frame

extraction; 11 filler;

12 - the idler; 13 - sterilizer.

The form is then fed to thaw. The next time the course

of the chain strap, frozen into a product, a special mechanism rise and pull

the melted block from the mold. Upon finding unit at the discharge conveyor

slats are rotated through 180 degrees and out of engagement with the unit. The

block falls on the output conveyor, and the strap re-introduced into the mold.

Single branch of the cargo conveyor is used for

sanitizing shapes and bars to extract the frozen material. In composition

washing device includes a washing tank for preparing the solution and a

centrifugal pump. The cleaning solution is sprayed nozzles, watering shapes and

strips, which are then washed, pure forms sterilized with steam and fed to the

filler.

Additionally, the apparatus of this type can carry out

production of edible ice for various purposes, frozen drinks, and some types of

ice-cream.