Danylova L.,PhD, Lanyn

O.

National Technical

University of Ukraine «Kyiv Polytechnic Institute»,

Kyiv, Ukraine

calculation

of the lead hole diameter for the UNC and UNF machine screw

In industry

and construction, Self-Drilling Thread-Forming Screws are used. Self-cutting

screws drill their own tapping hole to close tolerances and from their mating

themselves. The specially formed and stamped drill point prevents any drifting

around the surface of the component allows rapid spot drilling. There’s no longer

any need to centre punch the drilling point. No drilling or thread-cutting

tools needed, no additional securing elements needed. Thanks to this properties

self-cutting screws can be worked quickly and cheaply. Savings up to 50% are

possible compared with conventional tapping screws. Their effectiveness is determined by eliminating the

need to pre-drill holes in joined parts or extrusion of the threads and

accurate basing of the screw in the hole under the thread formation.

In general,

tapping screws permit rapid insertion because nuts are not used and access is

required from only one side of the joint. Mating threads created by these

tapping screws fit the screw threads closely, and no clearance is needed. The

close fit usually keeps the screws tight even when subject to vibrations.

Tapping

screws are used in steel, aluminum, die-castings, cast iron, forgings,

plastics, reinforced plastics, and resin-impregnated plywood. This method

provides a high yield, higher quality of connection, increase of static and

fatigue durability of screw-threads in comparison to screw-threads that are

cut.

Self-drilling screws for the application fixing to

steel, intended for drilling and tapping into layered or unlayered steel shall

be type ASD, BSD or CSD. TYPE ASD and BSD screw have spaced threads and type

CSD screws have threads of UNC machine screw diameter-pitch combination with a

60 degree basic thread form. Lead hole for thread traditionally defined on the ground of maintaining the constancy of volume before and after

plastic deformation, the various clarifications and limitations that take into

account the conditions of friction as strength, size tolerances. All these

specification necessary to reduce the likelihood for overflow profile of the thread. In case of the threads of UNC and UNF

machine screw lead hole for thread defined not only the constancy volumes before and after deformation, but the conditions of

similarity thread profiles on the screw and in the hole. Spaced threads forming the thread in the hole of a

different profile, so you can not apply the conditions are similar. Spaced

threads form the thread in the hole of a different profile, so you can not

apply the conditions of analogy.

Since the condition for preserving the

constancy of volume before and after plastic deformation abideth in strength,

it is necessary to determine the geometric parameters of the established

profile, such as raising the height of the deformed material. This can be done

using a solution of the classical problem of the theory of plasticity the penetration of

a smooth rigid wedge into a semi-infinite mass of rigid/perfectlyplastic

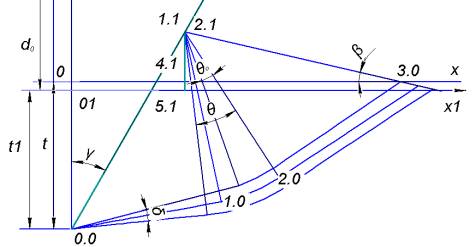

material. Based on the Figure 1 calculated

value of the diameter of lead hole for thread d0= (d-2t)/2+Dt. It

depends on the outside diameter d of the screw and of

indentation, the value of which is easily

determined depending on the desired size of the profile

height or taken from the drawing-rigid plastic region.

Figure.1. - The

scheme of the determination of the correction.

Method of

determining d0 is based on the classical problem of the theory of plasticity, such as solving the

problem of the penetration of a smooth rigid wedge into a semi-infinite mass of

rigid/perfectlyplastic material, to simulate any combination conditions of thread-formation (conditions of friction,

tightness, precision connection) for any combination s profile height and width

of the thread pitch.

This study

proposes an analytical model based on a study concerning radial penetration of

a rigid acute wedge into a perfectly plastic material. The method uses the

slip-line method with a model taking into account the interaction between two

consecutive formed threads and enables the mean pressure on the thread flank to

be obtained as a function of the formed thread height.

Figure 1 shows that

with increasing d

increased

free limits 2.1-3.0, which leads to the expansion of 2.1-3.0-2.0. This depth

introduction wedge t with

increasing d are reduced. According to the

theory Sokolovsky angles θ0 and β are independent of ![]() . The figure 4 depicts the variation of co-efficient of friction

with respect to semi wedge angle. With the increase of wedge angle the normal

force and tangential force increases. But, the variation of normal force is

very high. Again, it is clear that normal and tangential force increase with

increase of depth of indentation. But wedge surface pressure decreases with the

increasing wedge angle.

. The figure 4 depicts the variation of co-efficient of friction

with respect to semi wedge angle. With the increase of wedge angle the normal

force and tangential force increases. But, the variation of normal force is

very high. Again, it is clear that normal and tangential force increase with

increase of depth of indentation. But wedge surface pressure decreases with the

increasing wedge angle.

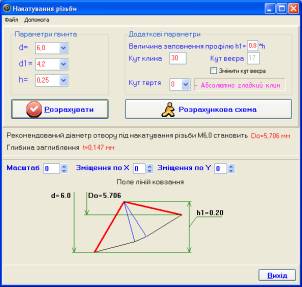

For calculating of lead hole for thread, propose program for visualization of the plastic

thread formed area. For specified parameters thread, friction coefficient and

filling thread profile is built right slip-line to

a particular case, taking into account the friction. The real picture of

deformation gives an opportunity to profile and overflow election under

diameter depending on requirements of threaded connection (Figure 2) .