Engineering sciences

Êumykova Ò., Kumykov V.

D. Serikbayev East

Kazakhstan State Technical University, Kazakhstan

Ways to stabilize the pressure of compressed air

in the shaft PNEUMATIC

NETWORK

Reasons for pressure falling in ore

mining pneumatic network and especially directly at the places of mining are

analyzed in the article. As a decision to this problem it is suggested to build

a compressed air accumulator (CAA) on the way of moving compressed air from the

compressor station to the consumer. It will allow smooth out peak-loads both on

ore mining pneumatic network and on energy system, increase productivity of

pneumatic-geared technological equipment, save electric power on generating

compressed air.

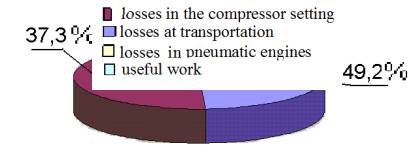

Transition to simulate mine lower horizons of the deposit

leads to an increase in the length of the pneumatic network and to removal of the

consumers of pneumatic energy from its source - the compressor station. The

effectiveness of the pneumatic network decreases with an increase in their

length due to growth in losses of energy of compressed air during

transportation to the consumer (Fig.1) [1].

Fig.1 - Diagram of energy losses

in the shaft pneumatic setting

The object of

research is the process of generation, storage, distribution and consumption of

pneumatic energy with the use of hydro-pneumatic accumulator (HPA) of

compressed air in pneumatic energy complex of an underground mine.

Work of major processing equipment (drill rigs,

loaders, etc.), by its nature is probabilistic, while the most natural mode of

operation of compressor units is a continuous mode, due to the difficulties of

starting and stopping power installations. These circumstances, in practice,

lead to the continuous fluctuations of the basic parameters of compressed air

(the flow and pressure) virtually in all elements of the pneumatic network. Thus,

the elements of the pneumatic network, of

which there is a direct intake of compressed air, are most likely to suffer

from the energy point of view of the situation.

At the same time, the parameters of compressed air at

the technological equipment have a direct impact on the performance of this

equipment. Thus, with increasing air pressure for 0.1 MPa, drilling

productivity increases at an average of more than 20%, with simultaneous reduction

in specific consumption of compressed air to more than 1,5 times. At the same

time, reducing the pressure in the faces below the nominal, leads to a sharp

deterioration in the performance of some pneumatic mechanisms.

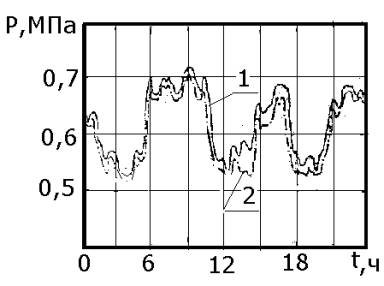

The investigation of pneumatic energy complex of Tishinsky

mine (Ridder, Kazakhstan) showed that the drop in air pressure at the

technological equipment during the work shift is 0.2 MPa (Fig.2) [1].

Fig.2

- Diagram of pressure in the main route of pneumatic gear (1) and in pneumatic

receiver (2)

The use of hydro-pneumatic accumulators of compressed

air (HPA) in the systems of pneumatic energy complex of mines allows upgrade

their work to a fundamentally new regime. One of the positive effects of

engaging the HPA pneumatic energy complex of a mine is that its presence allows

enclosing into specific characteristics of the compressor station and pneumatic

network into the specifications of HPA [2]. In first approximation,

specifications of GPA is a horizontal line ÐÃÏÀ= const.

But this option is valid only during active operation of HPA.

Engaging HPA in the pneumatic energy complex of a coal mine lets control the work of compressors,

regardless of the amount of intake of compressed air by coal mine pneumatic network

at each moment. This makes it possible to accumulate surpluses of compressed

air, available in the work of the compressor station in shift breaks, with its

subsequent applications using them for the shortfall in compressed air during a

working shift.

In addition, the presence of HPA in the pneumatic energy complex gives the possibility to manage the work of the

pneumatic system, not only by regulating the performance of compressor

stations, but also through the managing the regimes of accumulation of compressed

air in the HPA and harmonizing in timing its work with the work of a compressor

station.

To determine the parameters of compressed air, pressure

and temperature sensors were used, which had been installed at the exit from

the compressor station, the entrance to the mine’s pneumatic network, in pneumatic

camera of HPA and at points of mass air intake on the line from the compressor

station to the HPA.

During the HPA work the following was controlled: level of water in hydro camera of hydro-pneumatic accumulator;

air pressure in hydro camera of HPA;

air pressure in the pneumatic network.

In processing the results of measurements of compressed air in pneumatic energy complex without HPA the following was established.

Pressure of compressed air in the mine at idle pneumatic

receivers (rotary hammers, drills, etc.) varies between 0.5÷0.7 MPa.

Compressed air pressure in the working faces with pneumatic receivers working, varies

between 0.35 and 0.5 MPa, and air pressure equal to 0.4¸0.48 MPa is dominating. Duration of peak loads during the shift reaches 1.7÷3.4

hours, and dominated by yielding a peak period of 2.1

hours per shift.

Compressed air pressure at the compressor station in the period of

measurement fluctuates within 0.58÷0.8

MPa. Predominant pressure is equal to 0.6¸0,7 MPa. Fluctuation of compressed air pressure is equal to 0.22 MPa, predominant

air pressure ¾ 0.15 MPa. An average of 4 ÷ 5 compressors were running. Fluctuation

of compressed air pressure during a shift is 0.1÷0.3 MPa.

Processing of the data obtained with a running HPA showed that a most rational

mode of operation of the HPA allows use 3 compressors to during the work day. In this mode of

operation of compressor station air pressure in the working faces was equal to

0.56÷0.62 MPa, with a predominant

pressure 0,6 MPa. Fluctuation of pressure of compressed air was 0.04 ¸0.06 MPa, with a predominant pressure of 0.05 MPa.

Thus, the results of the investigations suggest that the presence of hydro-pneumatic accumulator in the system of coal mine pneumatic

energy complex leads the work of compressed

air network to a fundamentally new mode, in which the characteristics of both, the

compressor station and of the mine pneumatic

network, each separately, depend on the characteristics

of hydro-pneumatic accumulator [3].

Introducing HPA in the pneumatic system allows for the system of automatic

regulation of pneumatic

energy complex be carried out on

qualitatively new principles: by controlling the accumulation mode of compressed air in the HPA, and

harmonizing the work of the compressor station and HPA over time [4, 5].

Work of hydro

pneumatic accumulator in a mine pneumatic

energy complex permits increase the pressure

of compressed air in the working faces during a shift from 0.4 to 0.55 MPa.

The advantages of pneumatic systems with a HPA include:

compressed air is supplied to the process equipment with constant and

increased pressure, which increases its productivity;

a drier compressed air is supplied to pneumatic receivers, which

improves their work;

constant pressure benefits the work of compressors and pneumatic

receivers and increases their service life;

compressor stations can be designed not to "peak" loadings, but

taking into account the accumulation of air power in the HPA, which gives the

possibility to significantly reduce energy consumption in the systems and, in

some cases, reduce the number of operating compressors;

in the case of a short break in work of compressors,

pneumatic mining machines may be employed during some time receiving the

compressed air from the accumulator.

The most rational way of balancing peak loads, as in a

pneumatic system, the same as in the power system, is the use of underground

storage of compressed air in mines, which provide stabilizing and increasing

pressure of compressed air in the working faces, regardless of the number of

pneumatic receivers at work.

Using hydro

pneumatic accumulators of compressed air in the mines and quarries will provide

significant savings of electricity while developing compressed air and will

align the schedule of daily power consumption, allowing the processing

equipment work during the hours of peak loads on compressed air of the

pneumatic system, located in pneumatic camera of HPA.

References

1. Investigate the state of the coal mine pneumatic economy

of Zyryanovsk, Ridder, Irtysh plants and give data on its reconstruction / /

Inf. Map / VNIItsvetmet.-Ust-Kamenogorsk, 1995 .- 58 pp.

2.

Lisowski G.D., Kumykova T.M. Methods of stabilizing

work of shaft pneumatic network // Science and Education - a leading factor of

the strategy "Kazakhstan - 2030" / IY Proceedings of the

International Scientific Conference. - Karaganda: KarGTU, 2001. - S.

279-281.

3.

Kumykova T.M., Kumykov V.Kh. Energy conservation

in underground mines. Bdesheto problemite on svetovnata nauka. Material for a 4-and international scientific

practical conference. (17-25 December) Volume 23 Technology: ByalGRAD-BG Ltd. -

Sofia, 2008. - P.26-28

4.

Kumykova T.M., Kumykov V.Kh. Hydro

pneumatic accumulator of compressed

air. A provisional patent of the Republic of Kazakhstan for

the invention number 19314. Publ. 15.04.2008,

book. ¹ 4

5. Kumykova T., Kumykov V. Hydro pneumatic accumulator of compressed air. A provisional

patent of the Republic of Kazakhstan for the invention number 25580. Publ. 15.03.2012, book. ¹ 3