Utebayeba D.Z., Balgabekova L.U.

Almaty University of power

engineering and telecommunications

SIMULATION OF AUTOMATED MONITORING SYSTEMS

KEY

WORDS: SIMULATION, AUTOMATED MONITORING SYSTEM, SENSORS, THERMORESISTORS.

Currently,

the industrial enterprises are becoming increasingly urgent task of improving

the process of production management. It is particularly important solution to

this problem for those businesses or areas where the state parameters of

production decisive influence on the quality of products, and in some cases -

to life and health of the consumer (in the food industry, in homes or in the

manufacture of pharmaceutical products). Given a constant struggle for cost

reduction, production efficiency and competitiveness of their products, it is

necessary to ensure the correctness of managerial decisions and the adequacy of

the current state of the process. This can’t be achieved without the use of

timely and reliable information about the object at each level of production.

In addition to informed choice of hardware - sensors, communication lines,

transmitters - play a great role and software data. [1]

Energy

registration system allows for accounting of electricity and heat consumption

in the residential, commercial and industrial purposes.

Simulation

model - is a universal tool for studying complex systems, which is a

logical-algorithmic description of the behavior of the system components and

their interaction rules that display a sequence of events that occur in the

simulated system.[2]

Automatic

data collection commercial accounting of consumption (holiday) of electricity

at each point (group) accounting for the specified commercial ranges.

•

Storage parameters Registry database.

•

Ensure monitoring of compliance.

•

Derivation of design parameters for the terminal.

•

Maintain a single system time with the possibility of adjustment. [1]

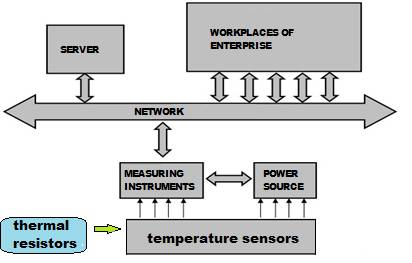

Figure

1 - The general scheme of the hardware of the automated monitoring systems

The

model is a complex set of software and hardware. The hardware part includes in

its membership the measuring equipment, real-time controller and temperature

sensors.

To

create such system is used modeling. However, regardless of the type developed

model, its purpose is to replace the complex original object and how can a more

accurate reflection of its basic properties.

The

proposed method of using simulation in solving technical problems of automation

of complex objects allows for the development of control systems, regardless of

the degree of readiness of physical objects. That is, when we do not have the

ability to use real devices, then we can replace them with affordable low-cost

electronics. A system is proposed for this use SCI resistor as a temperature

sensor.

The

essence of this method lies in the fact that the sensor is used as a type of

resistors SCI. That is, based on resistors sensors react to light, temperature

or pressure. Most of these are included as part of a voltage divider, which

varies depending on the resistance of resistors under the influence of changing

external factors. Resistance decreases and increases due to temperature.

Proposed

simulation model of automated accounting and control system can be used for

educational laboratories of creation of such

complex networks. The

real temperature sensors are costly for training purposes. In order to study and analyze the creation of such an automated system

in the conditions of educational laboratories as a sensor can be used thermal

resistors.

The

article revealed aspects of the design and implementation of simulation models,

in particular of such models, which replace the original object at its input

and output signals: signal control elements of technological equipment and

sensor signals, reflecting changes in process parameters.

REFERENCES:

1.

«Распределенная система

мониторинга климатических условий в производственных помещениях предприятия»., Кудрявцев С.А., Егорушкин Е.О.,

Кретинин О.В., 2012