*98823*

UDC

621.313.333.1

PROTECTION

SYSTEM OF SEMI-CONDUCTING RECTIFIER WITH APPLICATION OF MAGNETSENSITIVE

INSTRUMENTS

S.S.

Issenov, å-mail: isenov_sultan@mail.ru

Saken Seifullin

Agricultural University, Kazakhstan

At present about 1/3 of produced electric energy around the

world is transformed (with the help power electronics equipment) of before

utilization. Power electronics represents nowadays an electrotechnical sector.

Its output plays a vital role in electrotechnical and electric-power industries.

To prove that the following data are given below [1]:

1)

Annual usage volume around the world is (8…

12) *1012 K.W.H. Annual energy production expenses amount

400… 500$ billion. 72… 78$ billion amount real loss of generative,

transmitting and consuming objects;

2)

The main electric energy users are electric drives of various functions (51%),

lighting (19%), heating/cooling (16%), and telecommunication (14%);

3)

At present less than 25% of electric energy is used optimally to implement work

required (meaning loss minimization). This is achieved by application of

high-performance methods of electric energy network system’s controlled

transformation into energy of object control. The majority of such methods are

based on high-performance energy converters utilization.

The

progress in semiconductor electronics and transforming technique has influenced

greatly the electric-power industry development. Application of semiconductor

control systems and converters has made it possible not only improve some technical

and economic indexes of the systems exist, but also apply new principles of

control, the realization of which used to be unreasonable economically or

impossible technically. To supply different loads noncontrolled rectifier (NR)

is used in the number of direct-current and alternating-current drives. Strong

reliability demands are made of the system of noncontrolled rectifier – load.

That is why in order to protect the given system there are used quick-break

fuses and quick-operating catalyst and noncatalyst switching units and

protectors, which are installed at the point of entry and outlet of the

rectifier.

To

protect elements and optimize operating regime of noncontrolled rectifier -

load electrotechnical system improved in its characteristics (lack of contacts,

climatic impact resistance, and diminutiveness) a differential protection (DP)

is applied on basis of ferreed appliances. The high sensibility of

semiconductors’ electrical characteristics to different external actions

(magnetic field, temperature) makes it possible apply them as sensors that

measure and transform the corresponding impact magnitude.

Providing

overall protection is one of the solving ways in creation and perfection of

noncontrolled rectifier protection. The overall protection maintains the

rectifier elements and the whole system itself against possible emergency

state. A differential protection of

semi-conducting rectifier (SR) underlies the overall protection, taking into

account the most dangerous state that brings to overcurrent leaking.

There

is known the differential protection of NR [2]. One of its features includes

utilization of direct-current and alternating-current transformers as current

sensors. Here the direct-current transformer (DCT) is functioning as current

matching node at the NR indirect point of entry and outlet. This may be the

basis of the overall protection. However, it is necessary to perfect its

technical and economical indexes first: to exclude DCT, which doesn’t fully

meet the demands made to semi-conducting devices protection. It also requires

the break of output circuit of NR while examining, setup, or checking the DCT

and matching node. Moreover, while incrementing the noncontrolled rectifier –

load system the DCT mass and size indexes grow nonlinearly.

DP

is more economical when DCT functions are implemented by magnetic diode, which

is placed close to the NR output line or inside the resistor networked at the

outlet point of the NR. Application of high-speed protection system that forms

the basis of differential protection with direct-current and

alternating-current sensors is one of the solving ways of the problem set

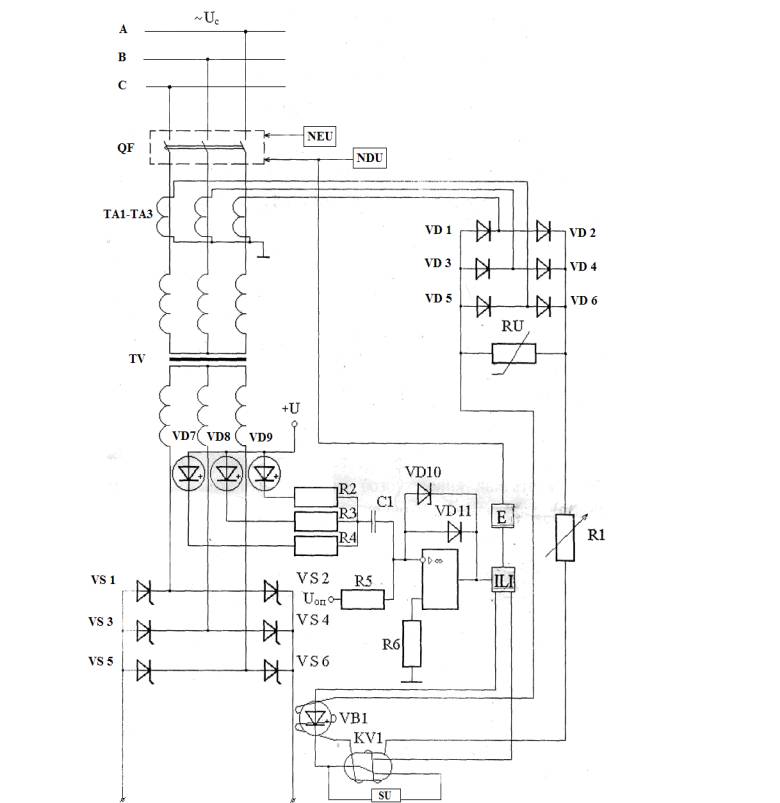

(picture 1).

While

connecting semi-conducting rectifier according to the bridge circuit

VS1÷VS6 to ac network through the switching unit QF and a transformer

TV, a load is linked up at its outlet point. At the transformer point of entry

TA1÷TA3 alternating-current sensors are placed, to their entry point the

VS1÷VS6 noncontrolled rectifier is networked. NR goes out through the RU

nonlinear element, R1 resistor, VB1 controlling bundles of magnetic diode, KV1

sealed switch, trough the ILI gating circuit and is connected with the effector

(E). At the transformer outlet point a velocity sensor of current change is

placed on the basis of VD7÷VD9 magnetic diodes. The velocity sensor is

networked with the second entry point of the ILI element through the

single-limit comparator with feed back (VD10, VD11) and C1 condenser, which

compares the velocity sensor of voltage build-up with voltage reference Ureference. The ILI element outlet point is

networked through the effector (E) with the outlet point of nonautomatic

disengage unit and the controlling entry point of the commutation unit

disengagement. VB1 magnetic diode is placed close to the ac busbar. During the

normal operating conditions of SR there is a signal at the outlet point of the

nonautomatic engaging unit (NEU) that provides the starting of the commutation

unit. So the SR is connected with the ac network through TV transformer and to

the load by means of ac busbars. At the

same time rectified current proportionate to current at the SR entry point is

running along the VB1 magnetic diode gate winding and KV1 sealed switch. VB1

magnetic diode is in off condition as 2 magnetic fields are applied to it: one

from the gate winding and another one from SR ac busbar. The magnetic flow of

the VB1 magnetic diode’s gate winding is regulated by current change in the

winding with the help of R1 resistor. Magnetic field created by ac busbar is

regulated by the distance change between the busbar and the magnetic diode or

by the angle change between them. Under the action of the magnetic flow of KV1

sealed switch’s gate winding the latter flips (front contact seals in and back

contact breaks) thus effector (E) input circuit is prepared to act, and

signaling unit’s (SU) input circuit breaks.

|

|

Picture

1 – Differential protection of the semi-conducting rectifier on magnetic diodes

The SU signalizes the

continuity of differential protection control circuit. There is no signal at

the first entry point of ILI element as VB1 magnetic diode is locked. There is

also no signal at the second entry point of ILI element because of the

comparator base, which does not act till the SR operates normally and current velocity

change di/dt at SR’s point of entry and consequently at the outlet point of the

current change velocity sensor is correspondent to the normal operating

condition of SR (di/dt<di/dtsteady). That is why there is no

signal at the entry point of ILI element and SR, and the commutation unit

remains engaged.

When

short circuit takes place in SR, at its entry and outlet points between the ac

busbars and in the load short-circuit current appears in the circuit between

the network and the short circuit point. At the same time short-circuit current

velocity exceeds greatly current velocity change controlled by the velocity

sensor of current change in the ac circuit at SR. That is why the signal at the

outlet point of the velocity sensor of current change is strong enough to make

the comparator base act (di/dt>di/dtsteady) and at the outlet

point of the latter a signal appears, which comes in the second entry point of

the ILI element.

At

the outlet point of ILI element a signal appears that comes in the entry point

of the effector (E). The effector (E) acts and gives signal to the commutation

unit’s controlling entrance. The latter acts and disengages the SR power

circuit from the ac network.

DP

also acts at overcurrent. Current increases proportionally at the SR points of

entry and outlet. However, magnetic fluxes influencing the VB1 magnetic diode

increase proportionally to the current of protection act, when the RU nonlinear

element goes into action. Then the RU nonlinear element limits the voltage at

the NR outlet point and therefore limits the current and magnetic flux of the

VB1 magnetic diode’s gate winding, it opens; at the first entry point of the

ILI element a signal appears and at the outlet point of the latter a signal

appears also. This signal sets the effector (E) going, and the commutation unit

disengages the SR from the ac network.

To

disengage the SR a signal is made by the nonautomatic disengaging unit (NDU).

The signal goes to the controlling entry point of the commutation unit

disengagement, which disengages the SR from the ac network.

Conclusion:

application of DP of semi-conducting rectifier helps cut maintenance charges.

There are several advantages of the DP application: the opportunity of full

interconnection of entry and outlet circuits, non-contact transformation of

little mechanical motions into electrical signals, magnitude detection and

direction of magnetic field induction with high locality, the “non-sparking”

mechanical commutator creation in circuits, and non-contact current test.

Literature

1. G.S.Zinoviev.

Theory of power electronics. Tutorial. 3rd edition revised and

augmented. – Novosibirsk. Publication of NSTU (Novosibirsk State Technical

University).2004.-672 p.

2. V.S.Kopyrin,

V.P.Markowskiy. Differential protection of the non-controlled rectifier – drive

winding system//Science and new technology in power industry of

Pavlodar-Ekibastuz region: thesis report. – Almaty, 1994. 68-71 p.