“Технические

науки” / 12.Автоматизированные системы управления на производстве.

PhD of Science Khakimyanov M.I., PhD of

Science Svetlakova S.V.

Ufa State Petroleum Technological University,

Russia

CONTROL OF SUCKER ROD PUMP UNITS WORK BY METHOD OF

ANALYSIS WATTMETER CARDS

Recently oil production

industry has been paying much attention to

the introduction of modern

automation technologies. Electric units of sucker rod pumps (SRP) are one of

the main objects of automation in the oil industry. This is due to their large

number and that they are scattered over the large area, as well as their distance

from the dispatch centers [1].

Modern controllers allow to

measure the electrical parametersof the motor SRP such as the input current,

active and reactive power, voltage level and power factor.

The efficiency and reliability of the

well-equipped SRP are known to directly depend on the proper selection of

equipment and balancing. Balance setting is determined by the analysis of

wattmeter cards. An analysis vattmeter card of SRP allows you to get the

electric power parameters, determine the characteristic fault ground and

downhole equipment.

To measure with the help of

wattmeter cards it is necessary to connect a measuring controller as shown in

Figure 1. Wires to measure voltage and current are connected to each of the

three phases [2].

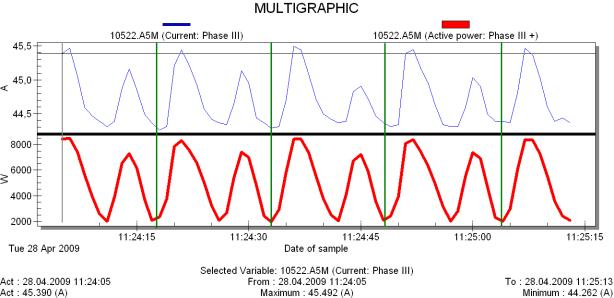

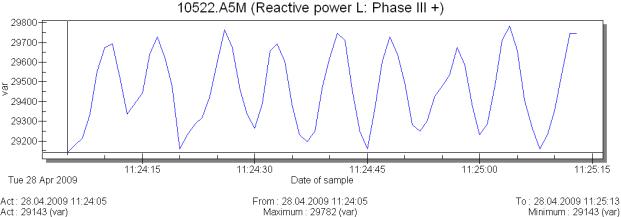

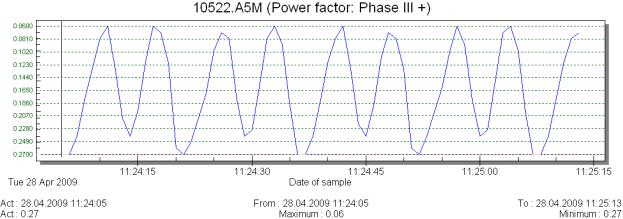

Figure 2 shows an example

of graphs of SRP electric drive parameters. The bold lines indicate the moments

of the rod passing the lower dead point or running start points.

As shown in Figure 2, the

current and active power peaks while the rod moving up and down are not the

same, indicating that the imbalance of SRP installation. Reactive power is

inductive (inductance caused by the motor windings) and significantly exceeds

the active power: 30 kVAr against 2 ... 8 kW. Moreover, reactive power in the

swing varies only slightly - no more than 2%, while the active power varies by

75%. Power factor changes from 0.06 to 0.27.

Figure 1 – Measurement scheme of electrical parameters of SRP unit motor

Obviously the installation

motor is greatly underused - the maximum active power is 8 kW of the installed

capacity 30 kW, which negatively affects the energy parameters.

The SRP balance can be

rated (measured) with the help of the current or active power [3]:

![]() ,

,

![]() ,

,

where DP and DI -

unbalance calculated through (using) power and current, respectively;

PU and IU

- peak current and active power while lifting rods;

PD and ID – peaks of active

power and current while downhill bars.

We obtain the following

values of unbalance for this well:

![]() ,

,

![]() .

.

Figure 2 – Graphs of SRP electrical

parameters change

Comparing DP and

DI it can be concluded that the assessment of SRP balance by current

is very rough, as the current varies a little because of the strong influence

of the reactive component of power. Thus, the balance assessment in the

technical availability should be carried out by the active power consumption by

the motor drive.

To summarize, we can

conclude that the control of electrical parameters is an essential factor in

SRP automation and should be implemented (realized) in all modern controllers.

In addition to the automation functions this equipment will allow to organize

the control of energy consumption in a particular well and enable their

integration into the systems of technical and commercial electricity metering.

References

1 How to

Maintain High Producing Efficiency in Sucker Rod Lift Operations: [site]. URL: http://www.rogtecmagazine.com/PDF/Issue_013/07_Maintenance.pdf.

2 Power

Current Transducer: [site]. URL: http://echometer.com/Default.aspx?tabid=107.

3 M.I. Hakimyanov, M.G.

Pachin. Monitoring of sucker rod pump units on result of the analysis wattmeter

cards. Electronic scientific journal "Oil and Gas Business", 2011,

Issue 5, pp. 26-36. http://www.ogbus.ru/authors/Hakimyanov/Hakimyanov_7.pdf.