Saidmurod

Sangovich Nazarov, Senior Teacher of the

chair “Mechanization of Processing of Agricultural Production and

Cattle-farms”, Tajik Agrarian University. Tajikistan.

Victor

Alexeyevich Muhin, Doctor of Technical

Sciences, Professor, Head of the chair “Mechfnization and Technology of

Stock-breeding”, Saratov State Agrarian University in honor of N.I.Vavilov.

Russia.

Andrey

Anatolyevich Zhizdyuk, Candidate of Technical

Sciences. Russia.

THE DIFFERENTIAL EQUATION OF RELATIVE MOTION FOR PARTICLES OF THE FEED RESIDUES

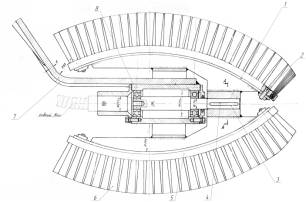

The article shows a diagram of

a rotational ellipsoid brush cleaner and shows the principle of operation of

the device. Theoretical studies of the dependence between the design parameters

of the rotary ellipsoidal brush cleaner and kinematic motions parameters of

feed residues particles. Determined relative velocity of particles is given and

an analytical solution of the equations about motion of a forage particles

residues (impurities). As a result these theoretical studies will allow in the

future undertaking the development of an installation for cleaning feeders.

Keywords:

Rotary

ellipsoidal brush cleaner, equations about motion of

forage particles residues (impurities), fodder rests,

blades, feeder, animal products, relative velocity of the particles.

After feeding the

animals, according to our observations, feeding remains a certain amount of

waste, these wastes reach 8-10% distributed forage, i.e. 300-400 kg in the

cowshed on 200 goals. Wastes

consist of different types of particles, from dry dust to wet stem. Uneaten

food mixed with distributed feed and worsen its quality, which ultimately

affects the productivity of animals. This is due to the hygiene of obtaining

animal products. Impurities impair the sanitary condition of the feeders, can

cause food poisoning and contribute to the spread of pathogenic microbes. So after each feeding trough must be thoroughly cleaned.

In this paper, we theoretical studies given the

dependence between the design parameters of the rotary ellipsoidal brush cleaner

and kinematic parameters of motion of particles of feed residues.

![]()

flexible shaft

![]()

Figure 1 - The scheme is

a rotational ellipsoid brush cleaner

The scheme is a

rotational ellipsoid brush cleaner shown in figure 1. The cleaning brush

consists of four blades. Brush blades are fixed to the casing 1 two screws 2 at

both ends. The casing is fitted on the shaft 3 by the key 4. Pads 5 of the

brushes are made from aluminium. Tufts of the brushes 6 of nylon filament 1.2

mm thick with diameter of brush 8 mm start. They form the blade. [1]

The shaft is

mounted in the bracket 7 in two radial-thrust bearings 8 inclined to the

horizontal and intersecting surfaces. Brush mounted above the trough bottom so

that its blade in contact with him get fit.

In the process of

cleaning a rotating ellipsoidal rotating brush moves toward the remnants of

feed at the bottom. Keep

blade brushes are shifted, and then released, picked up by the air flow through

the pneumatic transport serves in the cart.

In our case, the

process of movement of particles on the blades, located radially. Waste feeding will make

complex motion: relative on the blades and rotational. General theory of motion

of particles on rotary surfaces taking into account all the resistance forces

developed by academician P. M. Vasilenko. [2]

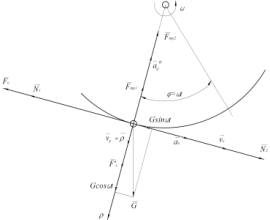

the Foundations of this theory and were adopted in the analysis of movement of

particles of the investigated material on the blades (figure 2).

Figure

2 - Dynamic diagram of the forces acting on the particle feed residues

Draw up the differential

equation of the relative motion of the particles of feed residues through a

rotating ellipsoidal brush cleaner. [3]

![]() , (1)

, (1)

where m – weight of particulate food residues,

kg; G – the force of gravity, N;

,

– the friction forces that depend on the action of gravity and of inertial forces kriolitovyjj, N;

– karaliova the inertial force, N;

– carrying the force of inertia, N.

The differential

equation of the relative motion after the transformation of equation (1) has

the form:

![]() , (2)

, (2)

where ![]() – the angular velocity of the

ellipsoid, rad/s; t – the adventures of the particles along the arc of the

ellipsoid, s.

– the angular velocity of the

ellipsoid, rad/s; t – the adventures of the particles along the arc of the

ellipsoid, s.

The force of

gravity is equal to:

G = mg, (3)

where g –the acceleration of gravity, m/s2.Friction force that depends on normal pressure N1 (including gravity):

Fòð1 = f N1 , (4)

where f1 – coefficient of friction; N1 – normal pressure, N.Normal pressure is equal to:

. (5)

Equation (4) with (5) has the form:

Fòð1 = f1

. (6)

Friction Fòð2 taking into account of the Coriolis forceis equal to:

Fòð2 = f2 N2 . (7)

The normal pressure N2 is:

. (8)

The Coriolis force is equal to:

, (9)

where– relative velocity, m/s;

– Coriolis acceleration of particles, m/s2,

.

Then the equation (7) with (9) is equal to:

Fòð2 = f2

. (10)

Carrying the force of inertia is equal to:

, (11)

where- portable centripetal acceleration, m/s2.

Then we have:

. (12)

After some transformations of equation (2) are as follows:

. (13)

Reducing weight (m) are:

. (14)

The differential equation has the form:

. (15)

Solution of these equations has the form:

; (16)

For

:

; (17)

; (18)

; (19)

; (20)

; (21)

. (22)

The second solution:

. (23)

Then we have the equations of motion:

. (24)

Differentiating with respect to time, are:

(25)

When t = 0

. (26)

; (27)

; (28)

. (29)

; (30)

; (31)

; (32)

; (33)

; (34)

The coefficients are equal:

; (35)

; (36)

. (37)

The relative velocity of the particles:

. (38)

An analytical solution to the equations of motion of the particles of the feed residues (impurities) and determined the relative velocity of the particles. These indicators will allow us to develop installations for cleaning feeders.

References

1. Nazarov, S.S., V.A. Muhin, N. Shamsiev, A.A. Zhizdyuk and H. Zaidov, 2008. Rotacionno-jellipsoidnyj shhetochnyj ochistitel' [A rotational-ellipsoidal brush cleaner. The registration certificate of intellectual product], 081TJ (81/08), pp:2.

2. Vasilenko, P.M., 1960. Teorija dvizhenija chasticy po sherohovatym poverhnostjam sel'skohozjajstvennyh mashin [The theory of motion of particles on rough surfaces agricultural machines] Kiev: Izdatel'stvo Akademii s/h nauk, pp: 284.

3. Muhin, V.A., A.A. Zhizdyuk and S.S. Nazarov, 2009. The differential eauation of relative particles’ movement of the fodder rests. The Bulletin of Saratov State Agrarian University named after N.I. Vavilov, 5: 61-65.