Õèìèÿ è õèìè÷åñêèå òåõíîëîãè / 5. Ôóíäàìåíòàëüíûå ïðîáëåìû

ñîçäàíèÿ íîâûõ ìàòåðèàëîâ è òåõíîëîãèé

Titova

Yu.V., Majdan D.A., Sholomova À.V.,

Aleksandrov D.Yu.,Khisamutdinova À.V.

Samara State Technical University

Preparation of aluminum nitride nanopowder using

SHS azide technology

A distinctive feature of nitride

compounds are broad areas of homogeneity where a great amount of vacant sites is

formed while their crystal structure is maintained. In addition, like many

other phases of implementation, nitrides are capable of forming numerous solid

solutions, many of which are distinguished by improved operating

characteristics.

The nitrides of elements of III

group (B, Al, Ga, In) and, particularly, aluminum nitride occupy a special

place among the nitride compounds. The application perspectiveness of AlN is

specified by the width of its band gap (6.28 eV), high value of the critical

electric breakdown, great heat resistance and mechanical strength [1]. Aluminum

nitride is the only ceramic material that has an extremely interesting

combination of high thermal conductivity and excellent insulation properties.

Due to this it is widely used in energetics and microelectronics. For example,

AlN is utilized in the manufacturing of printed circuit boards (substrates) in

semiconductors, it serves as a heat sink for the led lighting technology and in

high-power electronics. Moreover, aluminum nitride is viable for hardening

aluminum alloys operating at high temperatures.

Nowadays there is a huge number of

technologies for producing of aluminum nitride: direct nitriding,

plasma-chemical synthesis, carbothermic synthesis, chemical deposition from the

gas phase, the explosion of aluminum wire, etc.

This article [2] presents the

results of plasma-chemical synthesis of aluminum nitride nanopowder using

gaseous nitrogen and ammonia. A nanocomposite of Al/AlN with spherical

particles sized 50-100 nm is generated when pure nitrogen is used as a reaction

gas. Nitrogen content in the samples increases and the average particle size

decreases by adding ammonia.

Aluminum nitride was obtained by the

method of chemical deposition from the gas phase, using the system AlCl3-NH3-N2

[3]. Gaseous aluminum chloride, ammonia and nitrogen were reacted at a

temperature 1044 °C. The resulting powders’ particles have a spherical shape

and an average size of less than 0.1 micrometers.

In the following test [4] the

aluminum nitride was synthesized by the reaction of aluminum chloride and

sodium azide. The mixture was placed in a reactor with a nitrogen atmosphere,

and then the reactor was placed into a furnace for heating. The reaction

temperature of 450 °C was maintained for 24 hours. The synthesized product was

a micro-ribbon of AlN and bit long, straight fibers with a diameter of 40 to 60

nm and length of several micrometers.

The process of formation of aluminum

nitride in terms of electrical explosion of aluminum wire was investigated by

the authors of the present article [5]. As a result of the search for better

conditions of electrical explosion, a powder with a content of AlN equal to 93%

and a specific surface area of 14 m2/g.

However, these methods are

associated with large power inputs and high-cost and complex equipment is

required for them, the prepared powders have a strongly defect structure,

because of the shock cooling of the end-product. The self-propagating

high-temperature synthesis (SHS) of refractory compounds is free of these

disadvantages. It is characterized by low power inputs; short process duration;

high purity of products; the possibility to prepare new compounds, especially

multiphase composites, which are difficult to synthesize using other

technologies; and wide possibilities to control the dispersed structure of

powders from single-crystal grains to nanodimensional particles [6, 7]

The method is based on the

exothermic reaction of two or more chemical elements occurring in the

directional mode of combustion. The process is carried out in a thin layer of

the mixture of the initial agents after local initiation of the reaction

(ignition via electric impulse with a duration of 3-5 seconds) and

spontaneously propagates throughout the system due to heat transfer from the

hot products to original unheated materials that do not require energy input.

The authors [8] applied the SHS

method for the synthesis of highly dispersed AlN powder by combusting the

initial mixture of aluminum and gasifying additive (NH4Cl, NH4F) in the nitrogen medium. It is stated

that the degree of conversion of the aluminum to the nitride increases with an

increase in the proportion of aluminum in the charge and reaches a maximum

value (99.5 %) when the content of aluminum in the mixture in the amount of 50 wt

%. The particle diameter of the aluminum nitride decreases from 8-12 μm to about 1-2 μm, and the specific surface area increases up to 1.5 m2/g

with increasing of ammonium chloride proportion in the mixture up to 10 mass %.

Starting from 1970, the azide

technology of self-propagating high-temperature synthesis (SHS-Az) has been

developed at the Samara State Technical University. This technology makes it

possible to fabricate micropowders and nanopowders of nitrides and composites

based on them using the sodium-azide (NaN3) powder as the nitriding

reagent and haloid salts [9].

The goal of this study was to

investigate the possibilities of applying the SHS-Az technology to fabricate

the nanostructured aluminum nitride powder.

The stoichiometric equation of the

preparation reaction of aluminum nitride in the SHS-Az mode is as follows:

AlF3 + 3NaN3 =

AlN + 3NaF + 4N2, (1)

Na3AlF6 + 3NaN3

= AlN + 6NaF + 4N2. (2)

The usage of halide salts containing aluminum (AlF3,

Na3AlF6) instead of metallic aluminum as a starting component

reduces the combustion temperature and also enables the performing of the

reaction on the atomic level. In this case, it is possible to synthesize the

nanosized powders of aluminum nitride.

As the initial feedstock, we used the

sodium azide powder of the “Pure” grade (assay percentage 98,71 wt.%), aluminum fluoride

powder of the “Pure” grade (assay percentag 99,9 wt.%), sodium hexa-fluoroaluminate

powder of the “Pure” grade (assay percentag99,0wt.%), nitrogen gas quality “1” (assay percentag 99,99 wt.%).

The procedure of experimental

investigations in an SHS constant-pressure reactor with a volume of 4.5 L is described

in monographs [9]. The cylindrical samples (diameter – 30 mm, height – 45 mm)

of the initial powder mixture of the apparent density under an external

nitrogen pressure in a reactor of 4 MPa were combusted.

We investigated the phase and

chemical compositions, morphology, and particle size of combustion products.

The phase composition was determined using an ARL X’TRA automated X-ray

diffractometer. X’ray spectra were recorded using Cu radiation with continuous

scanning in angle range 2θ = 20°–80° with a rate of 2 deg/min. The surface

topography and morphology of powder particles were investigated using a

JSM-6390A scanning electron microscope.

To preliminarily analyze the

combustion temperature of the mixture of initial components and composition of

synthesis products, thermodynamic calculations were performed using the Thermo

computed program developed at the Institute of Structural Macrokinetics and

Problems of the Materials Science of the Russian Academy of Sciences

(Chernogolovka, Moscow region).

Table 1 presents the results of

thermodynamic calculations, which show the values of the adiabatic temperature,

reaction thermal effect, and composition of combustion products for the two

main compositions of the initial mixture, which differ in haloid salts.

Table 1 – Results of

thermodynamic calculations of combustion parameters

|

Composition no. |

Charge

composition |

Adiabatic

temperature [K] |

Reaction thermal effect [kJ] |

Synthesis

products [mole] |

||

|

AlN |

NaF |

N2 |

||||

|

1 |

AlF3+3NaN3 |

1682 |

–135 |

1 |

3 |

4 |

|

2 |

Na3AlF6+3NaN3 |

1269 |

–107 |

1 |

6 |

4 |

From the analysis of the presented

data for the compositions 1 and 2 follows, that the adiabatic

temperature and the thermal effect are higher while using aluminum fluoride as

a starting component than sodium hexa-fluoroaluminate. However, the yield of

the desired product - aluminum nitride is

the same in both speciations.

The results of the experimental

determination of the combustion temperature and its rate, as well as the phase

compositions under consideration, are presented in Table 2.

Table 2 – Combustion

parameters and composition of synthesis products

|

Composition no. |

Charge

composition |

Combustion

temperature[°C] |

Combustion

rate[mm/c] |

Phase

composition |

|

1 |

AlF3+3NaN3 |

1250 |

11 |

AlN, Na3AlF6,

NaF |

|

2 |

Na3AlF6+3NaN3 |

950 |

6 |

AlN, Na3AlF6,

NaF |

It appears from Table 2 that, while

using sodium fluoride the combustion temperature and its rate are higher, than by using sodium hexa-fluoroaluminate by 300 °Ñ è 5 mm/s correspondingly. The combustion products of both

speciations consist of three phases: aluminum nitride (AlN), sodium hexa-fluoroaluminate

(Na3AlF6) and sodium fluoride (NaF).

However, their ratio differs.

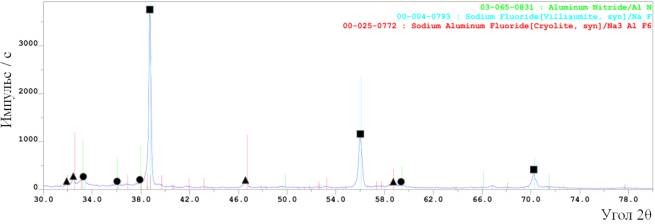

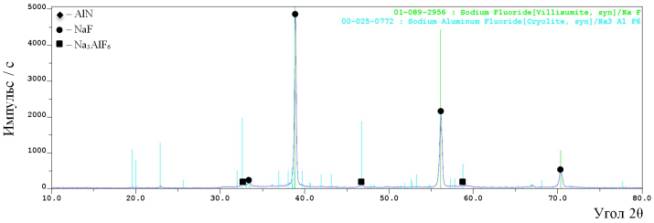

Figure 1 displays X’ray powder diffraction

patterns of synthesis flushed and unflushed products synthesized of the

speciation 1. the flushing was performed by diluting the

powders with distilled water in ratio

1:10, roiling the suspension and than filtrating the desired products in the

vacuum funnel. The filtered powder was blown dry to the constant weight in the

vacuum oven.

![]()

à)

b)

Figure 1 – The

results of X-ray phase analysis of the products, synthesized

of the mixture “AlF3+

NaN3”:

a)

before flushing; b)

after flushing

The X-ray

patterns demonstrate that the combustion produtcts of the temper “AlF3 + 3NaN3” consist of three phases:

aluminum nitride (AlN), sodium hexa-fluoroaluminate (Na3AlF6) and sodium fluoride (NaF). The peak

heights allow us to assume that NaF > Na3AlF6 > AlN.

The amount of the desired product - aluminum nitride is low, so that the X-ray pattern of the unflushed products there are no peaks of AlN.

A good solubility in water sodium fluoride is absolutely removed from the

combustion products after flushing in the distilled water. On the contrary, due

to bad solubility in water sodium hexa-fluoroaluminate exists in the combustion

roducts. The quantative phase composition

of the flushed combustion products of the temper “AlF3 + 3NaN3”

displayed the fraction of aluminum nitride – 64% and sodium hexa-fluoroaluminate – 36%.

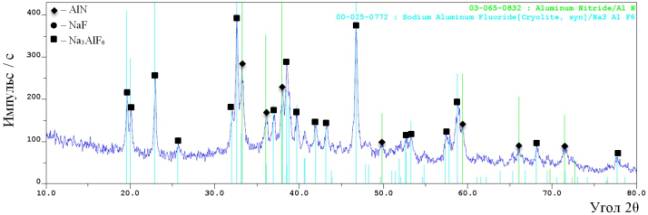

See figure 2. The X-ray

patterns of the unflushed and flushed produts synthesized form speciation

2.

à)

b)

Figure 2 – The

results of X-ray phase analysis of the products, synthesized

of the mixture

“Na3AlF6+ NaN3”:

a)

before flushing; b)

after flushing

The X-ray

patterns demonstrate that the combustion produtcts of the mixture

“Na3AlF6+ NaN3” consist of three phases:

sodium fluoride (NaF), sodium hexa-fluoroaluminate (Na3AlF6) and aluminum nitride (AlN). The peak

heights allow us to assume that NaF> Na3AlF6 >AlN.

The quantative phase composition of the flushed combustion products of the temper “Na3AlF6 + NaN3”

displayed the fraction of aluminum nitride – 61% and sodium hexa-fluoroaluminate – 39%.

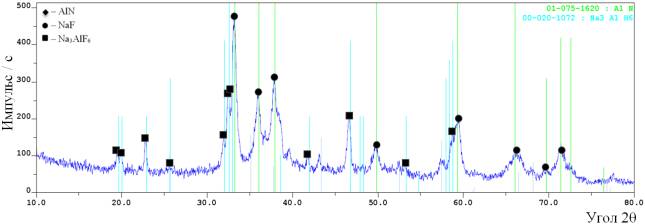

The process of flushing of sodium hexa-fluoroaluminate consisted of decomposing it into the fluorides of sodium and aluminum

which are soluble in water by heating them in Ar at a temperature of 400 °Ñ for 30 min and flushing it with water. This action allows extracting

the high purity aluminum nitride powder (figure 3).

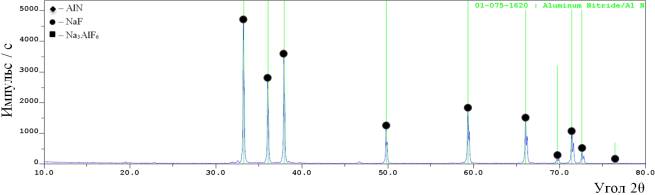

Figure 3 – The

results of X-ray phase analysis of the products, synthesized of the mixture

“AlF3+3NaN3” after been blown dry in the vacuum oven

See figure 3 we may see after been

dry in the vacuum oven the product consists of one phase - aluminum nitride.

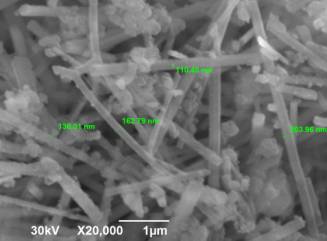

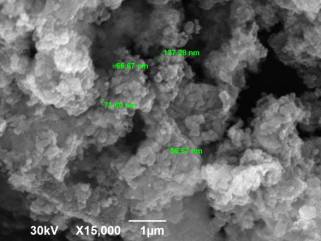

See figure 4. The photographs of

microstructure of the aluminum nitride powders synthesized of speciation 1 and

2

|

|

|

|

à) |

b) |

Figure

4. The microstructure of synthesized aluminum nitride powders:

a)

“AlF3+3NaN3”; b)

“Na3AlF6 + NaN3”

The picture displays a crystal whiskers structure of aluminum

nitride, synthesized of the mixture “AlF3+3NaN3”. The

whiskers have a diameter from 100 to 200 nm and in length they are about 5 µm.

Aluminum nitride, generated in the combustion of the temper “Na3AlF6

+ NaN3” has a structure of the spherical particles with a diameter

from 50 to 140 nm.

The applying of energy-saving SHS

azide technology allowed extracting high purity aluminum nitride micro and

nanopowders of the speciations “AlF3+3NaN3” and “Na3AlF6

+ NaN3”. It is of tremendous value for using them in electronics and

electric engineering. AlN is synthesized as the crystallized whiskers with the

diameter 100-200 nm and spherical particles with the diameter 50-140 nm

depending on the haloid salt used in the reaction.

Bibliography:

1. Yu.A. Bystrov, N.Z. Vetrov, A.À. Lisenkov. Plasmachemical

synthesis of aluminum-based nitride compounds in vacuum-arc discharge plasma // Technical Physics Letters (2012) Volume

38.20. p. 50-56.

2. Kim K. Plasma synthesis and

characterization of nanocrystalline aluminum nitride particles by aluminum

plasma jet discharge // Journal of Crystal Growth 283 (2005) 540–546.

3. Wu N., Tsai M., Wang M., Liu H. /

The morphology and formation mechanism of aluminum nitride nanocrystals

synthesized by chemical vapor deposition // Journal of Crystal Growth 208

(2000) 189-196.

4. Wang, H.L. Synthesis of hexagonal

AlN microbelts at low temperature // Journal of Alloys and Compounds. – 2009. –

Ð. 580-582.

5. Beketov I.V. Electric explosion

of wires as a method for preparation of aluminum nitride nanopowder // The

Second Russian conference of nanomaterials «NANO 2007» (13-16 march 2007, Novosibirsk)

– p. 109.

6. Levashov, E.A., Rogachev, À.S., Kurbatkina, V.V. Perspective materials and SHS technologies. Moscow, (2011) 377p.

7. Amosov, A. P., Borovinskaya,

I. P., Merzhanov, À. G. Poroshkovaya. SHS Technology of material synthesis: Educational

Aid / Amosov, A. P, Edited V. N. Anficerov. – Moscow: Machinery

-1, (2007) – 567 p.

8. Zakorzhevsky, V. V., Borovinskaya,

I. P., Sachkova, N. V. Aluminum nitrides synthesis through combustion of the mixture

Al+AlN // Inorganic Material, 2002. – ¹ 11. – V. 38. – P. 1340-1350.

9. Amosov, A.P. Bichurov, G.V. SHS

azid technology of synthesis nitrides micro and nanopowders. Moscow: Machinery-1,

(2007) – 526 p.