Engineering

/ 9. Aviation and Astronautics

MN Mukhtarova, AK Danlybayeva, AK Sariyeva, AI Kenzhebekova

Al-Farabi

Kazakh National University, Almaty, Kazakhstan

Instruments used for the visual

determination of the parameters for color change

Abstract: The

paper presents the block diagrams of devices that provide quality control

helicopter engine oil, fuel level measurement level, the thrust of aircraft

engines, the temperature of the heated bodies, the level of the two media

Keywords:

color sensors, helicopters, light-emitting diodes, aircraft, temperature,

thrust aircraft engines, fuel gauge, level gauges, optical pyrometer, optical

fiber, the quality of oil, bearings, hardening products from iron.

The last 25 - 35

years are increasing the quantity of publications and inventions in the methods of

manufacture color sensor - semiconductor devices, the maximum sensitivity which

is visible to the human eye. These color sensors can be used in such cases where the operator must

visually by a color change to determine or measure certain parameters. For

instance, quality of the oil in the tank on helicopters, which contains the

main bearings of the screw is determined every 50 or 100 flight hours. Herewith technician takes the oil into the tube

from tank in which are located bearings,

through which the helicopter's screw

rotates , and compares it with a butter color reference oil stored in

the cockpit of the helicopter. The fact is that the misalignment of the

helicopter propeller and shaft of engine, occurs the oil clouding, which is a

signal to the fact that the helicopter must be put on the overhaul. In

principle, this is a very important parameter. For continuous determination of

the oil quality in helicopter engines, has been proposed, "A method for controlling

the quality of oil helicopter engines and device for its realization" [7],

in which the definition of the oil transparency occurs by using color sensor,

which are placed outside the engine, but receiving information about the oil

color through fiber, which are inside

the tank motor, which, in which are bearings. In this case one fiber is

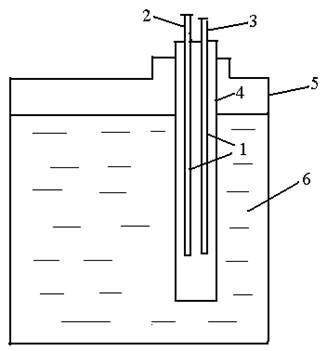

connected to the LED, and the other - with color sensor. Picture 1 shows an exemplary scheme of the device

for monitoring the quality of the oil helicopter engines. In principle, the fiber can be glued to the

wall of the oil tank - it will not be, practically, hold its scope.

Figure 1. An exemplary scheme of the device for

monitoring the quality of the oil helicopter engines.

1 – fiber; 2 – fiber coming from the LEDs; 3 – fiber connected to color

sensor; 4 – flat probe with reinforced fiber; 5 – oil tank with oil 6

Note that color

sensors [1] in the visible spectrum are more sensitive than the human eye. The use of optical fibers allows to

reduce the fire risk on board the helicopter. Similarly, the same device can be

used for continuous monitoring of the transparency oils in aircraft engines of aircraft, in which it

is important to oversee wear of the bearings

. It should be noted that last is

doing by a technician as well as on helicopters, visually through a certain

number of flying hours On airplanes

installs electric sensor that is triggered when into a small space between

its contacts appears dust from worn

bearings: it is usually a signal to put

the aircraft for overhaul. It should be noted that, apparently

monitoring the quality of the oil in the helicopter engines more important,

because its opacity connected with change of alignment in the alignment of the

main propeller, of the proper operation of which depends flight safety.

For aircraft in

the fuel gauge commonly used capacitive sensors, which determine the level of

fuel in the tanks. However, it is known that such fuel gauges have drawbacks,

chief among which are addiction of the temperature of their testimony, because

the dielectric constant of the medium depends on the fuel vapor between the

facings of the capacitive sensor, from which respectively depend on the indexes

of devices, as well as the grade of kerosene. In addition, a significant

disadvantage is the large size of the facings of the capacitive sensor, which

occupy a lot of space in the fuel tanks. In the proposed device for controlling the level

of fuel in aircrafts use color sensors, which connected to optical fibers of

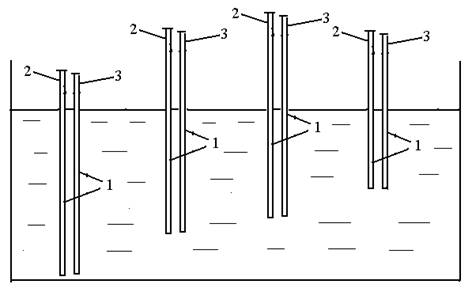

different lengths, which allows to determine the fuel level. Figure 2 shows an

exemplary diagram of the installation of optical fibers in a device for

measuring the level of fuel in aircraft.

Figure 2. An exemplary diagram of the installation of

optical fibers in a device for measuring the level of fuel in the aircrafts:

1 – the optical fibers; 2 – the optical fiber that comes from LEDs; 3 – the

optical fiber connected with color sensor

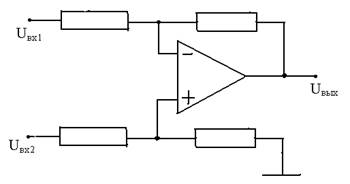

Herewith these

color sensors connected to difference

amplifiers (Figure 3), the second inputs of which are connected to the output

of the standard color sensor, the optical fiber which is at the bottom of the

tank, and the outputs of difference amplifiers via comparators or Schmitt's

triggers connected to a display unit or to a computer.

Figure 3. Scheme of difference amplifier:

Uвх1 – signal from color sensor; Uвх2 – signal from

standard color sensor

Critics may say

that the system is obtained optical and so it will be polluted. But in the case

of aviation fuel gauge where the medium is a jet fuel, such a system would be

operational.

For aircraft,

there is another problem associated with the measurement of aircraft engine

thrust, which values are usually determined by measuring the temperature of

exhaust gases using thermocouples [2, p. 7-28]. This method has the

disadvantage of relatively low precision instrumental error is caused by thermocouples. The disadvantage of this

method can also be considered that the thermocouple should be in contact with

the medium whose temperature is measured. When it comes to high temperatures,

typically use optical pyrometers [3, p. 86-92]. However, the latter have the

disadvantages, in particular an optical pyrometer readings disappearing

filament depends on the quality of

eyesight, a particular operator. Therefore, the high sensitivity of

color sensors can be used for measurement of aircraft engine thrust and ,in

principle, for the temperature of any heated body [4] in a contactless manner,

as long as it has changed the color of the body. You can also use color

sensors in installations for hardening

products of iron [5].

An important

parameter in the production of yellow phosphorus is determining his level under

a layer of water. The fact that, as is known, white or yellow phosphorus must

always be under a layer of water, as the

in contact with air it ignites

spontaneously. At the same time by the phosphorus level in the tank usually

determine the amount of phosphorus - this is very important, because the

company needs to know how much phosphorus it sells. In actual production, this

parameter is usually determined with a ruler at the tip of which is attached a

small scoop, by which is captured a

small amount of phosphorus, which ignites in the air and on the basis of it the

operator concludes that it reached the level of the phosphorus by using the

ruler. It should be noted that for the combustion of phosphorus is released

harmful gases, among which is considered detrimental phosphine. It is clear

that all this is very inconvenient. For this case, it was proposed "Device

for measuring the level of the two media" [6], wherein two color sensors

being disposed at a small distance from each other in a tube of transparent

material and separated by two light-proof partitions, between which there is a

light source. In

this case, the signals from these color sensors

fed to the inputs of a differential amplifier which provides at its

output a signal equal to zero, if color sensor in one environment and a

stronger signal, if the lower color sensor enters the medium with another

color, and the signal of this sensor will be different from the upper signal of

color sensor.

As a result,

modern color sensors having spectral sensitivity of the human eye, can be used

when creating new instrumentation.

REFERENCES:

1.

Beck V.G and oth. A new type

of semiconductor of color sensor// Vestnik KazNU. Physics. -1994.

2.

E.A Gritsenko, the chief

designer. Engines family of NK-8. Effect of washing-gas path of the engine to

operate at its parameters // Technical Report TS-1004-84. -1984. - P. 7-28.

3.

Kulakov M.V Technological

measurements and devices for chemical industry / M.: Publishing house

"Engineering", 1983. - P. 86-92.

4.

RK Patent № 15047,

15.09.2009. Tuyakbaev AA Aldamzharov KB, Tuyakbaev SA, DA Tuyakbaev Temperature

measurement method RK // Patent № 15047, 15.09.2009. Bull. Number 9.

5.

The patent number 30678,

12/15/2015.Tuyakbaev AA Askarova, SA Bolegenova SA Installation for hardening

products from iron // Patent № 30678, 12.15.2015. Bull. number 12

6.

RK Patent № 4770, 16.06.1997. Tuyakbaev AA Tuyakbaev

SA, Tapalov TT, Baekenov MA, Sadikov AA, AN Kosilbekov Apparatus for measuring

the interface level between two media of Kazakhstan // Patent № 4770,

16.06.1997. Bull. Number 2

7.

Prepatents RK № 15341,

17.01.2005. Tuyakbaev AA Aldamzharov KB, Artemyev VL Tuyakbaev SA A method of

controlling the quality of oil helicopter engines and device for its

implementation // RK prepatents number 15341, 17.01.2005. Bull. №1.