Trunov V.S, Mochalov A.S,

Koltsova E.A.

Ivanovo State Power

Engineering University

DEVELOPMENT OF APPARATUS AND

SOFTWARE COMPLEX FOR SCANNING OF THREE-DIMENSIONAL OBJECTS

The paper deals with scanning of 3-dimensional object techniques. As 3D

modeling has become popular in engineering and designing, the issue of

obtaining 3D computer model from an existing object is of great importance. Some

complicated objects contain an enormous amount of smaller details and their

modeling can take quite long. Therefore, this process requires automation.

This research aims at developing a device which is able to scan 3D

objects and obtain a computer model represented as a point cloud for further

transformations into well-known editors' formats. This device is expected to meet next

requirements:

1. The computer model should be precise, it is to exactly

copy the object (all the complex parts it consists of must be reflected in the

model).

2. The device software is required to be open-source and

free. Documentation of how to deploy and use it is expected to be

published.

3. All the calculations this device performs are to be

sped up to minimize the time of scanning.

4. The device is required to be as cheap as possible, it is

to contain only the elements which can be easily purchased. Everyone should be enabled

to assemble such a device.

To achieve the aim, the following research methodologies were employed:

1. Experimental study for improving the main procedure of

model obtaining and speeding up the calculations.

2. Correlation study to determine the relationship

between the quality of obtained model and device parameters such as the frequency

of step motor and the angle between the camera and the source of laser beam.

Device

hardware and components

The list of

included components is represented below.

1. Arduino Uno Computing platform.

2. Nema 23' Stepper Motor.

3. ULN2003 Unipolar stepper motor driver on

microcircuits.

4. Power Supply of 12v 300w.

5. 800x600 Web-camera.

6. The case of a cubic form with a side of 0.5 m and a

rotating disk (platform).

7. 22' LED screen.

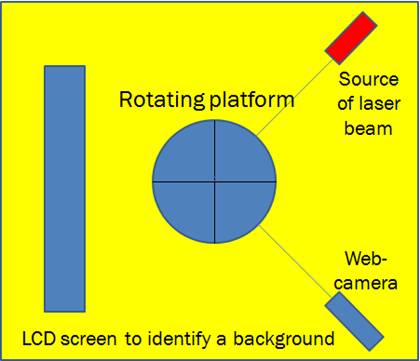

The schematic

diagram of the device is shown in Figure 1.

Fig.

1. Schematic diagram of the device.

For object scanning it was decided to put the camera and the source of

laser beam statically (they aren't moving throughout the whole scanning process)

and to move the object around the axis of rotation. The vertical laser beam

passing through the middle of the rotating platform falls on the object

outline. The web-camera takes pictures of that object with the laser beam on

its surface. The platform keeps rotating and the camera keeps taking pictures

until the whole object surface is handled. Device components are put in the

special box with the walls covered with light-absorbing material to absorb the

laser and prevent its reflection.

Device

software

The

software presents the mathematical solutions listed below.

1. Laser recognition.

2. Distance measuring of the laser beam.

3. Plane transformation (from 2D plane to 3D).

4. Object representation in computer memory.

Let us consider each item in more detail.

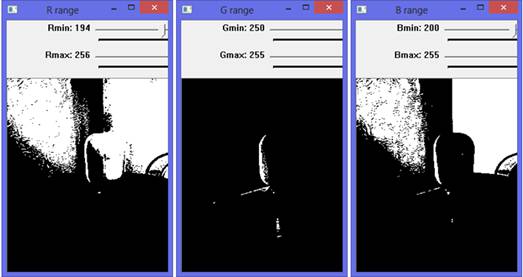

Laser

recognition

The laser line should be the brightest in the picture,

the color of it should be known. There is a way to select a laser line from an

image by decomposing the image into RGB streams. The algorithm has been

developed with the help of C++ and OpenCV framework.

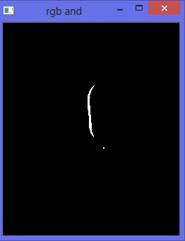

In figures 2-3 the experiment of laser recognition is presented.

Fig. 2. Stream decomposition

of an image. Threshold determining for each stream.

Fig. 3. Logical

multiplication of streaming images and receipt of recognized laser line.

Distance measuring of the

laser beam

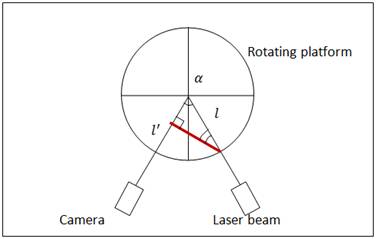

As the camera and the source of laser beam are situated

at an angle, the camera takes pictures of distorted laser line. Therefore, it

is necessary to calculate the precise distance to the laser beam. The issue is

presented in Figure 4.

Fig. 4. The issue of laser

beam distortion.

The line ![]() (red line) is a

line the camera views,

(red line) is a

line the camera views, ![]() is a precise

one. To calculate

is a precise

one. To calculate ![]() it is necessary

to apply the following formula:

it is necessary

to apply the following formula:

Plane transformation (from 2D to 3D)

The stepper motor rotates the object at 1°. As a

result, 360 two-dimensional planes are obtained (the z coordinate is zero). To

set the z coordinate, the following conversion should be applied:

,

,

where ![]() ,

, ![]() ,

, ![]() are new

coordinate values;

are new

coordinate values;

![]() ,

, ![]() - coordinates

of laser points;

- coordinates

of laser points;

![]() - coordinate of

object rotation axis;

- coordinate of

object rotation axis;

![]() - angle of rotation around

the axis. If the rotation angle of the stepping motor is 1°,

- angle of rotation around

the axis. If the rotation angle of the stepping motor is 1°, ![]() equals to the number of current plane in 360

two-dimensional plane list.

equals to the number of current plane in 360

two-dimensional plane list.

Object

representation in computer memory

It has been decided to represent the object model in computer memory as

a point cloud. In other words, the model is saved in the memory as a list of

point coordinates. The point cloud allows converting to well-known editors'

formats (for instance, AutoCAD). To prove the correctness of a point cloud

which looks like the scanned object surface it was decided to build its

axonometric projection. The transformation is performed due to the

multiplication of the coordinates matrix by the transformation matrix presented

below:

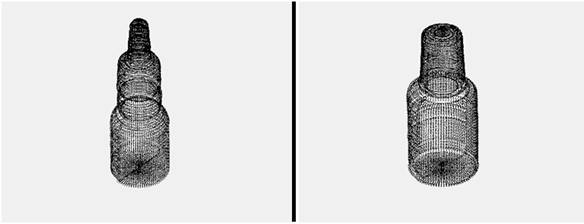

In figure 5, the models of scanned white-out bottles are represented.

Fig. 5. Models of scanned white-out bottles

To summarise, all the goals of the study have

been achieved. As we have seen, the 3D scanning device has been assembled and

tested with several objects with all obtained models being highly precise. The

cost of the device is approximately $100, which is relatively inexpensive. The

key findings of this research have already been published in some scientific

journals in Russia. The device has practical applications with a lot of

positive feedback.

The current research contributes substantially to the objects copying

techniques. It will prospectively allow developing and assembling the copying

object device in the future.