Строительство

Совершенствование

экспериментально-лабораторной базы исследования сцепления

бетона с опалубкой

Жайлаубеков Алмас

Шариханулы

Студент-магистрант 2

курс

Казахский национальный технический университет имени К.И. Сатпаева,

г.Алматы, Республика Казахстан

E-mail: almaszhailaubekov@mail.ru

a

candidate for a Master's degree Zhailaubekov A.Sh.

Kazakh National Technical Univercity after K.I. Satpayev

Almaty, Republic of Kazakhstan

E-mail: almaszhailaubekov@mail.ru

Improvement

of experimental and laboratory research base of concrete adhesion with

formwork.

ABSTRACT.

In this article from the standpoint of

manufacturability, cost and complexity of pilot plants presented allowing for

experimental studies of different types of lubricants, in order to identify and

reduce the adhesion of least effort vouchers, including at low temperatures.

Keywords.

Designing pilot plants, concrete formwork adhesion,

adhesion and cohesion of the concrete, the plane of contact with the concrete

formwork, breakout force when removing the formwork.

From an economic point of view, the complex process of

monolithic construction of basic structures, is the dominant method of

construction, as it requires considerably lower energy consumption, consumption

of concrete and formwork, and as a result, more than 15% lower financial costs.

The most time-consuming technological conversion there are formwork. Their

labor intensity varies from 40 to 55% of the total labor input, and the cost is

estimated at 30-45%, respectively. For every cubic meter of monolithic

structures necessary to install and remove from 3.0 to 8.0, and in thin-walled

structures to 12.0 m2 of formwork. Application of lubricants inefficient

shuttering or general application, as often happens in practice that increases

complexity demolding 70-100%, while because of the high clutch Stripping large

effort and mechanical action on the formwork at its purification 70% of

premature formwork building and faces after stripping require mnogozatratnoy

posleraspalubochnoy finishing. It is worth noting that the work is aimed at

addressing the potential of reducing the cost of stripping and improving the

quality of construction can not be relevant.

In this connection, the problem of underestimating the

importance of technological operation lubrication on the formwork, attributing

it to the category of minor, and sometimes unnecessary, (the period of contact

with the concrete formwork creates favorable conditions for the manifestation

of the clutch) and the predetermined goal of theoretical and experimental

studies of the influence of adhesive and cohesive properties of the concrete

formwork with the forming surface during its removal.

Based on the above, it sets the main goal - the

determination of indicators affecting the construction of monolithic high-rise

buildings, with step by step solution to the underlying problem of the design

of experimental facilities for future studies grip concrete formwork.

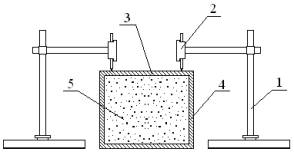

The authors have designed and prepared for the

experimental setup in experimenting pioneer (Figure 1) intended for holding the

samples in specific conditions of real structures, allowing for experimental

studies of various types of lubricants in order to identify and reduce adhesion

least vouchers effort, including greases used in zero temperatures:

The experimental apparatus №1 consists

of two side fastened together tayrotami and two face sheets of plywood deck

pretreated with inner surfaces, various types of lubricants. The main elements

of the module and are loading devices, guide blocks, the site of attachment,

traction ropes and measuring the load.

The experimental

apparatus №1

251658240

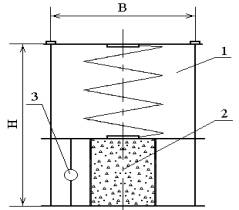

To measure the shrinkage humid offered special unit

number 2, where linear (three-dimensional) deformation of concrete is

determined using dial gauges. To this end, during vibration of the concrete in

the form of a 10cm edge on the surface of the plate stacked polished aluminum

1mm thick. Deformation of each sample was determined by two dial gauges every

4h in the first day from mixing with the mixture, and then twice a day for 14

days.

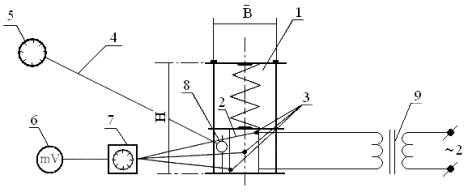

In the case study species expanding

concrete be used in an experimental setting number 4 is a torque jig,

consisting of three cross-pieces - the lower, middle and upper interconnected

rods which serve to support the spring, which creates a strain related linear

expansion of concrete. Measurements of strain as a result of expansion of the

concrete produced in the conductor set a dial indicator. To produce the samples

used cylinders GOST 10180 D = 71,4 mm, h = 143 mm. After dialing the stripping

strength of a sample of extruded through a die cylinder on the press with

metering in special place pull force.

|

The experimental apparatus № 2 251658240 1-stand; 2 - indicator of hour type ; 3-aluminum plate; 4-metallic form; 5 – concrete. |

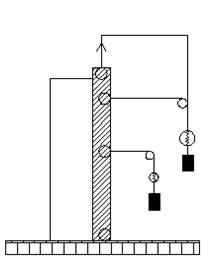

The experimental apparatus № 3

2-

cylinder; 3- indicator. |

The experimental apparatus № 4

251658240

1 – dynamometric conductor; 2 - electric cylinder; 3 –

sensors of temperature control in section of sample; 4 – sensot of

temperature control in mode; 5 - potentiometer; 6 -

micro-voltmeter; 7 – ten point switch; 8 - indcator; 9 –

laboratory transformer.

In order to simulate the contact heating concrete (for

lubricants used at low temperatures below -s ° C.) Developed an experimental

setting number 4, the prototype of which was the installation № 3. What metal

molds (cylinders) were converted into the electric cylinder (by winding the

layer of asbestos spiraling output 350B, which in turn is protected by a second

layer of asbestos). The specified temperature and humidity conditions of

keeping the samples were maintained test equipment. The sensors monitor the

temperature of the regime were Chromel-Copel thermocouple fastened on the deck

of cylinders.

The advantage of these methods for

determining strain detachable effort strength and methods of holding the

samples, in addition to simplicity lies also in the fact that the samples in

the required amount may be in the conditions of curing concrete structures,

thus providing a real picture of the material.