Elina Khobotova

ELEMENTAL COMPOSITION OF

ASH-SLAG WASTES OF SLOVIANSKA

THERMAL POWER PLANT

The low-waste technologies stimulate the use of industrial wastes in

various branches of industry. Blast-furnace slag has the properties

of effective broken slag, ³t can be used for manufacturing various types of cement.

Wastes of the power engineering industry are fuel ash

and slag. Ashes from TPP carry-over are widely used for manufacturing cement

and various types of concrete, for manufacturing bricks and light porous fillers, as well as in road building. However, at the

majority of TPP ashes and slag are removed hydraulically. Thus, the ash-slag

being inhomogeneous by its structure and properties gets into dumps and that

complicates its further use.

The conclusion about the use of ash and slag for some

definite purposes can be made only after preliminary determination of their

elemental, chemical, mineral composition and granularity.

Identification of the class of ash-slag wastes

radiation safety is also of great importance. Ashes and slag are the components

of the technogenically changed radiation background.

Their uncontrollable application in the manufacturing of building materials can

increase the gamma radiation intensity, external irradiation doses due to electromagnetic

radiation, and the internal irradiation doses while inhaling radon isotopes.

The aim of research was to make a conclusion that ash and slag wastes of Slovianska TTP could be used in construction based on

determination of their elemental and chemical composition.

Research of the ash-slag wastes composition. Distribution

of ash-slag samples by granulometric fractions was

carried out by means of sieve sets. The granularity of ashes varies widely.

More often ashes of hydro dumps have a polydisperse

composition with predomination of small fractions. The maximum size of ash

particles is

The results

of the gamma-spectrometric research of ash-slag wastes.

Gamma-spectrometric analysis was performed on the scintillation gamma

spectrometer SEG-001 "AKP-S" which measures the range of energy of

gamma radiation from 50 to 3000 keV. The time of

measuring activity of natural radionuclides makes up

4 hours on average. To process the results of measurement program Akwin is used. The results of gamma-spectrometric analysis

of ash-slag wastes have shown that their fractions include 40Ê and

two representatives of radioactive families 226Ra and 232Th

(Table 1). The isotope 40Ê share is the biggest in the total

activity (more than 80 %). Efficient specific activity (Cef) of slag fractions does not

practically change as well as the content

of

particular radionuclides in it. Hence, there can not

be a restriction in the use of particular granulometric

fractions in construction. According to Cef values of ash-slag and its particular

fractions, they refer to the first class of radiation safety at the value of Cåf![]() 370 Bq/kg. Such materials can be used in construction without

restriction.

370 Bq/kg. Such materials can be used in construction without

restriction.

Table 1 − The results of gamma-spectrometric

analysis of fractions of ash-slag wastes from the Slovianska

TTP

|

Fraction, mm |

Ñåf., Bq/kg |

Ñsum., Bq/kg |

ѳ, Bq/kg (% content) |

||

|

40Ê |

226Ra |

232Th |

|||

|

<5 |

237 |

897 |

745 (83 %) |

83.4 (9.3 %) |

68.6 (7.6 %) |

|

5-10 |

269 |

984 |

807 (82 %) |

104

(10.6 %) |

72.9 (7.4 %) |

|

>10 |

264 |

966 |

792 (82 %) |

100

(10.4 %) |

73.5 (7.6 %) |

The results

of electron probe microanalysis of ash-slag fractions. Electron microprobe analysis (EMPA) is carried out by

the scanning electron microscope JSM-6390 LV INCA with the system of INCA

x-ray microanalysis. The x-ray microanalysis gives an idea

about the elemental composition of fractions. The fraction <

Table 2 − The results of the

electron microprobe analysis of fractions of the Slovianska

TTP ash-slag wastes (mass part)

|

Element |

Fraction, mm |

||

|

<5 |

5-10 |

10-20 |

|

|

C |

28.92 |

0.00 |

0.00 |

|

O |

48.86 |

63.87 |

56.75 |

|

Na |

0.43 |

0.96 |

0.79 |

|

Mg |

0.45 |

1.27 |

0.94 |

|

Al |

4.72 |

8.80 |

12.19 |

|

Si |

9.46 |

17.70 |

19.96 |

|

S |

0.27 |

0.10 |

0.35 |

|

Cl |

0.10 |

0.00 |

0.00 |

|

K |

1.18 |

1.37 |

2.26 |

|

Ca |

1.40 |

2.10 |

1.34 |

|

Ti |

0.28 |

0.23 |

0.48 |

|

Fe |

3.92 |

3.59 |

4.94 |

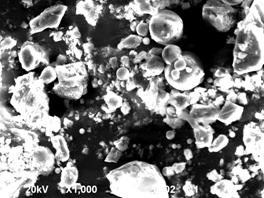

The method makes it possible to study the

morphological features of the sample surface. Conglomerates of aggregates

sintered with each other in contact are the prevailing spatial form (Fig. 1). The

availability of organomineral aggregates in fractions

worsens the quality of ash from a perspective of its use in concrete. The

fraction of 5–

a b

Fig. 1 – The surface of the <

The microelemental analysis

showed the full absence of organic components. The mass fraction of silicon

(17.7 %) follows oxygen (63.87 %), then come aluminium

(8.8 %) and iron (3.59 %). The silicon content has increased 1.87 times, aluminium – 1.86 times, the iron content practically has

not changed in comparison with the fraction <

The results of the

electron microprobe analysis of the fraction of 10–

Conclusions. The elemental

composition of fractions is different; fractions include glass as a material

without the crystal structure; there are also differences in granulîmetrical

properties of slag fractions; materials can be used in construction without any

restriction.