Engineering / Automated control systems in manufacturing

1MN Mukhtarova, 2RB Akhmetkaliev, 1AK Danlybayeva, 1AK Sariyeva, 1EM Zulbukharova

1Al-Farabi Kazakh National University, Kazakhstan Republic

2Almaty University

of Power Engineering and Telecommunications, Almaty, Kazakhstan Republic

Structure

of the technological complex

The mobile technological complex consists of three

main principally new devices : a rotary hydraulic (hydrodynamic) mill (RGDM), a

multicommodity multi-product hydrocluster (CIM) and centrifugal concentrators

(CCC).

The hydrodynamic mill (MHD) is a kind of rotary

hydraulic cavitation mill, designed for finely grinding various materials of

any strength and abrasiveness. The mill can provide grinding of granular

material to a size of 0.1 microns (a characteristic feature - the thinner the

grinding of the raw material is required, the more effectively the hydrodynamic

mill operates), and also for mixing various liquids, liquids with gas and solid

materials.

Experimental-industrial tests of a mill with a

productivity of ~ 100 t / h have confirmed the high efficiency of grinding. At

the same time, it became necessary to increase the wear resistance of the mill

units. This problem was solved by the method of electropulse hardening of the

working surfaces of the mill and the use of special polymeric and metallic

nanopowder materials.

The technical and economic comparison of the rotary

hydraulic cavitation mill (RHCM) with serially produced domestic and foreign

vibro-ball mills indicates that the rotary hydraulic mill with the same degree

of grinding is almost five times less than the energy consumed per 1 ton of the

raw material . Its mass is 30-90 times, and its dimensions are 7-10 times

smaller than in the best vibro-ball mills. In addition, the new mill easily

fits into the technological line for hydraulic processing of granular

materials, since it can suck in and pump up the original pulp to a height of up

to 20 m or more.

Multicommodity shelf hydroclassifier (CGS) provides

effective separation of various granular materials at any size and density,

including fine particles, as well as productive and quality enrichment and

separation of such materials by fractions with different granulometric and

chemical compositions of the incoming slurry.

As a result of studying the process of precipitation

of suspended grains of minerals in laminar flows, it was possible to separate

fine-grained materials with relatively high accuracy, and also to brighten the

polluted waters.

The dependence of the distribution of various

components of the slurry (noble and heavy metal ores, mercury-containing

components, and other toxic products) on the zones of MGC is established. The

distribution is determined by calculation, allowing to establish a qualitative-quantitative

plot of precipitation of various components in different zones of multi-product

hydroclassifier.

The enlarged characteristics of shelf

thickeners-hydroclassifiers of different firms are given in Table. 2.

Advantages of a shelf thickener-thickener: own weight and production cost are

reduced by 1.7-2.0 times, and the simplicity of the design allows it to be

manufactured in small workshops. The latter is achieved due to the transverse

(horizontal) flow direction in the interlam space, when the liquid phase of the

pulp-flows perpendicular to the direction of the sediment movement.

Table. 2

Comparative data of shelf thickeners of hydroassifiers

|

Characteristic, indicator |

Form-developer (manufacturer) |

|||

|

Ecoresources Hydrotechnics |

Uralmashobr |

Research Institute Hydromechanism |

Denver (USA) |

|

|

Output by initial pulp, m3 / h |

165 |

165 |

165 |

165 |

|

Total mass, t |

12.0 |

24.0 |

28.0 |

23.5 |

|

Overall height, m |

3.0 |

6.0 |

9.0 |

11.1 |

|

Cost of production, thousand rubles. |

400 |

780 |

840 |

1600 |

|

Laminarization of the flow

(liquidation of the counterflow) |

stream

laminarity |

missing |

missing |

stream

laminarity |

|

Flow direction |

horizontal |

vertical |

vertical |

combo |

The horizontal arrangement of the thickener with

several bunker discharges of condensed products compared to vertical

single-bunker designs of shelf thickeners made it possible to reduce the

overall overall height of the apparatus by 1.5-2 or more times.

Centrifugal concentrator gives off heavy metals, incl.

And mercury containing, as well as gold and platinoids from technogenic wastes

(tailings) of concentrating plants. With this method, extraction of heavy

metals, incl. Mercury-containing and precious metals, from tailings will be

95-99%. After the recovery of heavy metals, it is possible to use waste as

building materials and, in particular, as a backing material for underground

mining. Land that has been freed from the tailings, after reclamation, can be

used for farmland, construction and other areas of economic development.

The proposed technology makes it possible to use

environmentally friendly solvents for the transfer of precious metals into the

ionic form and to extract them on selective ion-exchange filters having a fiber

base. It is also promising to use ceramic filters.

The proposed technological complex and the equipment

included in it have no analogues in the world practice of hydraulic processing

of granular materials due to their efficiency, low material intensity and cost.

The novelty of technical solutions is protected by more than ten author's

certificates of inventions and patents.

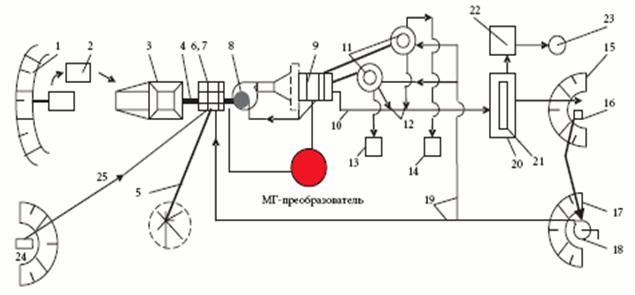

The technological complex works as follows (ðèñ.1): waste (tails) from the tailings (tailing dump)

are transported (2) by road (3) to the receiving hopper through the grate

screen, which releases inclusions of fineness +50 mm. Sand from the bunker with

the help of a belt feeder and a tray (4) is fed to the vibrating screen (6),

mounted above the sump (7). Pulp preparation is carried out by supplying

technical water to a tray, a vibrating screen and a sump in a volume of 3-4 m3

/ t of the starting product. The oversized product of the vibrating screen (+2

mm ... 50 mm) is fed by a conveyor (5) belt to the storage area, and the

sub-product (-2 mm ... +0 mm) from the sump in the form of a slurry flows

through the suction nozzle into the cavitation hydrodynamic rotor mill (8).

Here, grinding (dispersing) occurs, the disclosure of fine-grained materials

due to high-intensity hydrodynamic impacts and cavitation.

![]()

Fig. 1 Diagram of connections of devices of an autonomous mobile

technological complex for processing and utilization of technogenic and

natural-technogenic deposits

The destruction of the intergrowths of the minerals of

heavy metals (Cu, Zn, Pb, Kd, Se, etc.) in noble metals (gold,

platinum, palladium, silver) with quartz and other minerals occurs on weaker

metal contacts with nonmetals Effect of Rebinder),

which to a large extent facilitates the removal from the tails of RP of

mercury, heavy metal toxins and precious metals.

From the mill, the pulp is sent to multi-product

hydrocracker (MGC) (9), where the stream is laminated in a labyrinth of

parallel plates and is divided into fractions characterized by the density and

granulometric composition of the granular material that settle on inclined

surfaces made of special material (lamellas). The fractions (+0.2 mm ... 2.0

mm) are separated in the first compartment of the hydroclassifier, which are

sent to a hydrodynamic mill for re-grinding by a vibrating screen (6). In

subsequent sections, minerals, heavy metals, mercury, harmful components are

released, Cu, Zn, Pb and others.

In the lower storage chambers of MGC (9), precious metals and heavy metals, as

well as other ores, are enriched to a concentration of 10 times or more from

the initial (1st stage). Further (up to 80%), most of the pulp with dissolved

toxins, radionuclides and other fine dispersible harmful inclusions through the

drain pipe of the hydroclassifier is sent to the thin-layer settler (20). From

the accumulating lower chambers of the hydroclassifier, the enriched slurry of

minerals is sent to the second stage of

enrichment in concentrators (11), in which the degree of concentration

of metals increases by 2-3 orders of magnitude (for example, 2-3 kg / t of the

starting product in gold with an annual concentrate output of 8-20 Tons).

From the concentrators (11), the bulk of the pulp in

the form of an obsolete product, the yield of which is more than 90%, with the

toxins and radionuclides dissolved in it through the fixed drainage boxes and

the waste pulpwood (10) is sent to the thin-layer settler (20) with the

coagulator (21). In the settling tank the slurry with finely dispersed

particles (less than 5-40 microns) is condensed with the help of coagulator to

the state T: Æ = 1: 1. The condensed fine suspension with demilitarized

products sent to the storage card – blade (15), which has a dumping well (16).

Clarified water with dissolved toxins and radionuclides is sent to the

radionuclide and toxin (22) release unit, after which they are sent to the

respective disposal facilities of radioactive waste and toxins (23). Purified

from fine particles and harmful impurities, the technical water from the well

enters the sedimentation pond (17), from where it comes from a circulating

water pump (18).

Bibliography

1.

Latyshev, P. N.

Directory CAD. Programs and manufacturers: Catalogue edition. — Moscow: publishing

house of SOLON-PRESS, 2006, 2008, 2011. — 608, 702, 736 S. — ISBN

5-98003-276-2, 978-5-91359-032-9, 978-5-91359-101-2.

2.

Muromtsev Yu.

l., Muromtsev D. Yu., Tyurin I. V., etc. Information technology in the design

of electronic equipment: proc. a manual for students. ouch. uchebn.

institutions. — M.: Publishing center "Akademiya", 2010. — 384 p. —

ISBN 978-5-7695-6256-3.

3.

Norenkov I. P.

fundamentals of CAD: proc. for higher education institutions. — 4-e Izd., Rev.

and extra — M.: Izd-vo MGTU im. N. E. Bauman, 2009. — 430 p. — ISBN

978-5-7038-3275-2.

4.

Norenkov I. P.

computer-aided design. Tutorial. — M.: Izd-vo MGTU im. N. E. Bauman, 2000. —

188 p