Ôèçèêà / 2.Ôèçèêà òâåðäîãî òåëà

Titova Yu.V., Majdan D.A., Sholomova À.V.,

Aleksandrov D.Yu., Khisamutdinova À.V.

Samara State Technical University

Self-Propagating High-Temperature Synthesis

of Nanostructured AlN Powder with the Use of AlF3 and NaN3

One fundamental base of technological advance is the development of new

materials meeting demands of modern technology. In 1967, when studying gas-free

combustion of mixtures of powders of metals and nonmetals, Russian scientists

(Academician A.G. Merzhanov, Professor I.P. Borovinskaya, and Professor V.M.

Shkiro) in the academic borough of Chernogolovka near Moscow developed the new

synthesis of compounds, including nitrides, which was called self-propagating

high-temperature synthesis (SHS) [1].

In 1970, Professor V.S. Kosolapov of the Kuibushev Polytechnic Institute

proposed using powders of solid inorganic azides, the application of which

increases concentrations of reacting substances in the synthesis zone and

eliminates filtration difficulties, instead of gaseous nitrogen as the

nitrifying reagent in SHS [2]. This is the beginning of azide technology of

self-propagating high-temperature synthesis (SHS-Az).

The investigation into the synthesis conditions and properties of

aluminum nitride AlN is considered in numerous publications [3-9], the results

of which were the origin of its application in modern engineering. Aluminum

nitride has a forbidden band of 6.2 eV with the direct transitions, which is

close to dielectric. Its resistivity is very high (greater than 1011 Ω), whereas permittivity is very low. Because of these

properties, AlN is ideally appropriate for the use as a material of electronic

substrates or the package of integrated circuits. It also has a low thermal

expansion coefficient of 4.3 × 10–6 K–1 and a high

thermal conductivity of 320 W m–1 K–1,

which is three times higher than for aluminum oxide, while it is the most

valuable known ceramic material [10].

The aim of the given work is to investigate the process for obtaining

the nanostructured powder of aluminum nitride in the SHS mode at the excess

pressure of nitrogen using sodium azide and aluminum fluoride.

The stoichiometric equation for the chemical reaction of obtaining

aluminum nitride in the SHS-Az mode is the following:

AlF3 +

3NaN3 = AlN + 3NaF + 4N2. (1)

In this study we investigated

the combustion temperature and rate of the starting component mixture under

conditions of a laboratory reactor with a constant pressure [2] and the

chemical and phase compositions of combustion products as a function of the

pressure of gaseous nitrogen in the reactor, the relative density of the

starting mixture, and the sample diameter.

Based on the

obtained data and technological considerations related to the use of pressing

equipment, it is appropriate to use the apparent density of the charge for the

further investigations. It is evident from data that the combustion temperature

and rate of the AlF3 + 3NaN3 system increase

with increasing sample diameter D

attaining the maximum at D = 3 cm.

Exceeding this value causes filtering difficulties for the nitrogen supply into

the central part of the sample. External nitrogen participates at the after burning

stage, which is why the desired product with a high N content forms [11]. Based

on these data, we chose a sample diameter of 3 cm for the further investigation

of the AlF3 + 3NaN3 system.

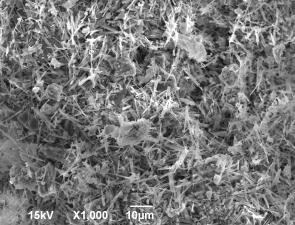

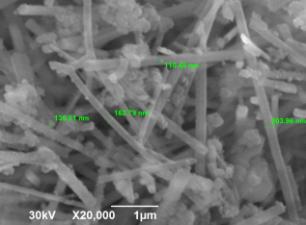

The surface

topography and particle sizes of the AlN powder synthesized from the AlF3 + 3NaN3 system are shown in Fig. 1. It is evident from the presented

photographs that aluminum nitride is synthesized in the form of particles

containing whiskers ~100 nm in diameter, which can be classified as nanofibers.

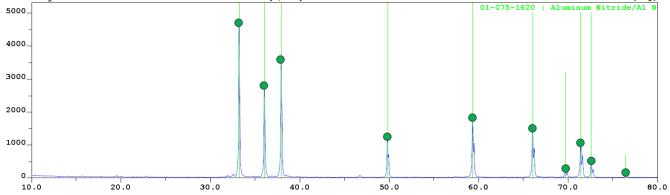

Data of X-ray

analysis (Fig. 2) testify that reaction products contain three phases: aluminum

nitride, sodium hexafluoroaluminate, and sodium fluoride. The last two

components are present only in unwashed combustion products and are removed by

washing in distilled water.

|

|

|

|

a |

b |

Figure

1 – Surface topography of AlN powders synthesized in the “AlF3 + 3NaN3”

system:

(a) ×1000 and (b) ×20000

Figure

2 – X-ray diffraction pattern of the washed product synthesized

in the “AlF3 + 3NaN3”

system

Let us note that

the binary system that we investigated makes it possible for the first time to

synthesize the aluminum nitride powder in the form of nanofibers.

References

1. Amosov, A.P.,

Borovinskaya, I.P., and Merzhanov, A.G., Powder Technology of Self-Propagating

High-Temperature Synthesis of Materials: Moscow: Mashinostroenie-1, 2007.

2. Amosov, A.P.

and Bichurov, G.V. Azide Technology of Self-Propagating High-Temperature

Synthesis of Micropowders and Nanopowders of Nitrides, Moscow:

Mashinostroenie-1, 2007.

3. Kosolapov,

V.T., Shmel’kov, V.V., Levashev, A.F., and Markov, Yu.M., 2nd All-Russia Conf.

on Technological Combustion, Chernogolovka, 1978, pp. 129-130.

4. Prokudina,

V.K., Shestakova, T.V., Borovinskaya, I.P., et al., Problems of Technological

Combustion: Proc. 3rd All-Russia Conf. on Technological Combustion,

Chernogolovka, 1981, vol. 2, pp. 5-8.

5. Zakorzhevskii,

B.B., Borovinskaya, I.P., and Sachkova, H.B., Inorg. Mater., 2002, vol. 38, no.

11, p. 1131.

6. D’yachkov,

L.G., Zhilyakov, L.A., and Kostanovskii, A.B., Tech. Phys., 2000, vol. 45, no.

7, p. 928.

7. Borets-Pervak,

I.Yu., Kvantovaya Elektron., 1997, vol. 24, no. 3, pp. 265-268.

8. Grabis, Ya.P.,

Ubele, I.P., and Kuzyukevich, A.A., Latv. PSR Zinat. Akad. Vestis., Ser.

Khimiya., 1982, no. 3, pp. 279–282.

9. Titova, Yu.V.

and Shiganova, L.A., Proc. Int. Theor. and Pract. Conf. “Modern Innovations in

Science and Technology”, Kursk, 2011, pp. 113-115.

10. Samsonov,

G.V., Nitrides, Kiev: Naukova Dumka, 1969.

11. Bichurov,

G.V., Self-Propagating High-Temperature Synthesis of Nitrides with Application

of Inorganic Azides and Halogen Salts, Extended Abstract of Doctoral

Dissertation, Samara: Samara State Tech. Univ., 2003.