Undergraduate Kaldybaev Ò.S.,

c.ò.s., professor RÀS Kolesnikov À.S.,

PhD doctor Zhakipbayev B. E., c.t.s. Kocherov Ye.N., master

Estauova À.À., master Êulmahanova À.N., master Besbaeva N.À., master Àykenova S.Zh.,

master Shegenova G.Ê., master Êàsimova Zh.Zh., student Ayazbekov M.

A study

of aluminum-containing accelerators used for Torbert concreting

At the present time when carrying out concrete work, which require quick

setting and hardening concrete and mortar additives are put accelerators of setting

and hardening. Instead of alkaline additives are increasingly used supplements

boosters that do not contain compounds of alkali metals, with the purpose of

increasing the strength at the later stages of hardening and resistance of

concrete to internal corrosion caused by the interaction of alkalis with

aggregate and thereby increase the durability of structures made of concrete.

Of particular importance supplements boosters have sprayed concreting when the

concrete mix with the concrete spraying machine is supplied under pressure and

compacted under the action of impact. In shotcrete adhesion of concrete or

mortar mix should occur within seconds. As alkali-free accelerators are the

most used aluminium compound is a finely dispersed amorphous modification of

hydroxides and oxides of aluminum, aqueous solutions of sulfates and

hydroxocuprate aluminum. High reactivity of these additives in cement paste

caused by intensive education in the interaction with components of the test

vysokoplotnogo hydrosulphate-minata calcium 3CaO∙Al2O3∙3CaSO4∙32H2O

(ettringite phase).

The rotor is a high - tech way of concrete, which are nowadays solved

various tasks in the construction industry, mining, agriculture. Invented in

the early XX century in the USA, this mechanized method of laying concrete

quickly spread worldwide [1,2]. The rotor allows you to perform special, a

particularly challenging work such as tunnel driving, fastening the coastal

slopes, the device shaft lining and many others. With more than 90% of the

total use of concretestone have to mount mine

workings [2]. The use of this technology in Kazakhstan has received active

development in recent years is that associated with the construction of sports

facilities in Almaty and Astana for holding the Asian games, the development of

the metro. To build infrastructure in the mountainous terrain necessitated the

construction of long transport tunnels.

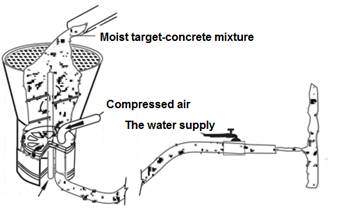

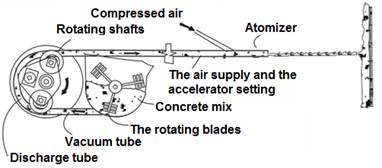

In shotcrete, the concrete mixture using a

special device (shotcrete machine)is applied to the

surface under pressure and compacted by the impact energy [2]. Layers of Torreblanca, in some cases reaching a thickness of more

than 25cm, and must quickly gain a firm foothold on rough vertical surfaces,

the vaults of tunnels, mines, hard to reach areas and components of the

equipment. In addition, when spraying should be provided with minimum rebound

of the concrete mix. The rotor may be "dry" or "wet"

methods [3-4]. During the "dry" shotcrete

at the nozzle of the gunning apparatus with compressed air is a dry mixture of

components (aggregate, cement, powdery additives), where it is mixed with water

or an aqueous solution of additives and then discharged onto the surface. When

wet spraying in the nozzle of the gunning apparatus is supplied ready concrete

mixture, compressed air and a solution of additives (figure 1).

a

b

Figure

1 – is a Conventional diagram of the installation for the preparation of

sprayed concrete in the dry (a) wet and (b) methods of production [5].

With its advantages of wet shotcrete method to date, is

most prevalent, especially when performing major works.

As subjects of the study selected highly dispersed

amorphous aluminum hydroxides, one of which is a product of Russian manufacturer (JSC "Boksitogorsky alumina") of AmGA,

another product of the company "Industrias Químicas del Ebro"

(Spain) Geloxal. Chemical composition of aluminum hydroxides according to the

manufacturers is presented in table 2.

Table

2–Chemical composition of aluminum hydroxides

|

¹ Number of indicator |

Íàèìåíîâàíèå ïîêàçàòåëåé |

Name of indicators |

Geloxal |

ÀmGÀ |

|

1. |

Mass fraction of Ñl- |

% by weight. |

not more than 0,5 |

– |

|

2. |

Mass fraction of SO42- |

% by weight. |

not more than 2 |

– |

|

3. |

Mass fraction of SiO2 |

% by weight. |

– |

0,16 |

|

4. |

Mass fraction of Na2O |

% by weight. |

not more than 1 |

0,15 |

|

5. |

Mass fraction of Al2O3 |

% by weight. |

50 |

50 |

Thus,

the requirements of modern accelerators for shotcrete

are not only in the fact that at a moderate cost, they provided almost

immediate grasp of the concrete mix and quick set early strength, but also in

the fact that they do not adversely affect the properties of concrete in

adulthood and did not serve the cause of reduction of its durability.

Bibliography

1.

Yoggy,

G.D. The history of shotcrete / Shotcrete.

2005 (Summer). P. 26–32.

2.

Melbye,

T. Sprayed concrete for rock support / Garshol – MBT

International Underground Construction Group, Division of MBT: Switzerland-

2001. -247 pp.

3.

EFNARC (1999) – Guidelines for Specifiers and Contractors: UK- 1996. – 35 pp.

4.

William, D. Brown. Standard practice

for shotcrete. Engineer Manual No. 1110–2–2005.

Washington – 1993 – 49 pp.

5.

American Concrete Institute ACI

506R–90: Guide to Durable Concrete. Farmington Hills. –1995. – 41 pp.