Технические науки. Отраслевое

машиностроение

Alex Maslyakov

Kuzbass State Technical University, Russia

Improving pre-mounting passed

dismantling generation

On the domestic and foreign mines

widespread technology assembly and dismantling work using pre-traveled

dismantling workings. To maintain pre-traveled dismantling mines used roof

bolting and stationary lining in the form of wood fires, mine uprights. Analysis

of the experience of the pre-fixing traveled dismantling workings in coal mines

revealed that there is a problem of attachment. Existing types of stationary

lining does not meet the requirements of strength and stiffness, resulting in a

collapse of the roof in the development of dismantling and accidents at the

entrance to her cleaning mechanized complex (OMC).

Typical mounting

dismounting single generation in Kuzbass mines is that the roof

is fixed rope anchors

and props wooden

racks. The disadvantages of this lining is the lack

of compliance and load-bearing

capacity.

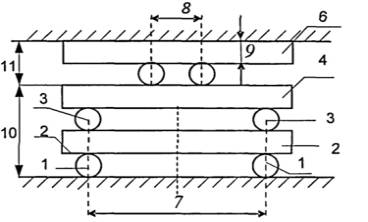

Known method of

building a camp fire lining

for mining in the development of stratified deposits (Figure 1). The technical result is to increase the

pliability of the wooden crib by creating a beam

system with the redistribution of loads of rock pressure on

the middle of the lining elements campfire. Campfire lining includes tiers of lining

elements Four campfire.

In addition, it is equipped with one or two tiers of flexible

elements crib stacked on the hard part of the elements Four campfire lining.

This flexible elements are shifted to the center of a camp fire lining, and

the relationship between compression force of rock pressure, falling to one corner of the

crib, and its deformation.

The disadvantage of this method of

construction is insufficient

bearing capacity of the lining does not allow to apply the lining to be stored

for re-use and innovative workings [1].

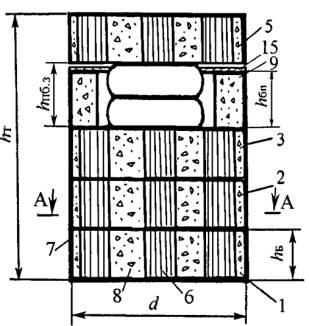

There is also the method of

building stone for the maintenance

of reusable development workings

(Figure 2). The technical result is to increase the efficiency of the tables by creating pre-thrust

when it is installed between the side

rocks. Bollard to maintain reusable

development workings includes a cylindrical timber-concrete blocks mounted on

each other at a height equal power excavated layer made of wooden racks,

installed in a metal cage and secured in a holder hardening solution. Cupboard

equipped with an additional constituent unit comprising a hollow cylindrical

block bellows 13 with a nipple 14 consists of two segments joined by a clamp, a

solid cylinder block, gasket placed between the rear segment and a cylindrical

timber-concrete.

Fig.1 Campfire

lining increased compliance.

1-4 - the lining

of the campfire tiers;

6 - compliant

elements of the crib;

7 - the distance

between the axes of the elements rigidly campfire

lining;

8 - the distance

between the axes of the elements of a compliant cog; 9 - the diameter of the lining elements campfire; 10

- the value of the hard part; 11 - the value of the

pliable.

Fig.2 Stand

for the maintenance of reusable development workings.

1,2,3,5 - individual

cylindrical wooden and concrete blocks; 6 -

wooden racks; 7 - a metal clip; 8

- curing the

composition; 9 - segment; 15 - a lining.

The disadvantage of this

method is that it does not

satisfy the conditions of fracture

harvester as wood-concrete

blocks are metal cage

[2].

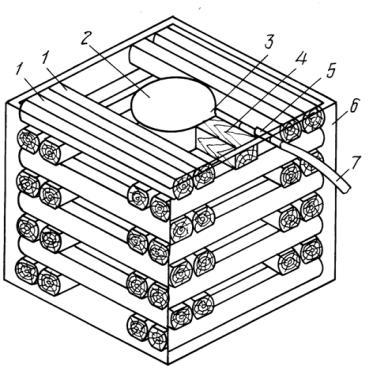

Also, there is a campfire limited

compliance (Figure 3). Koster to protect excavation workings involves a convoy

of pro-dolgovato boards installed in pairs around the perimeter of the fire

with ligation at right angles on the edges of each pair of two adjacent pairs.

The price-fire central part has a cavity into which the inner formwork, such as

in the form of an inflatable elastic membranes. The outer shell has an opening for fitting. Hardened materials only filled the voids

between the wooden elements and the corners of the cavity with a hose, the

hoped-Con to the union. As a result of performing the fire hardening material it

adheres to the rough surface of wooden elements, making them work together,

even under the action of forces on a security structure deviated from the

normal. Intimate contact with the surface of the cured material of the soil

eliminates point loads, to destroy-ing it. The presence of wooden elements into

the design to provide security Vaeth its compliance to 25% which excludes

destruction of hardened mother la the inevitable shift of the main roof.

Therefore, when working in the fire mode, it pliable bearing capacity is not

reduced [3].

Fig 3. Fire limited

pliability.

1 - wooden

elements; 2 - elastic shell; 3 - the

valve; 4 - a wooden tube; 5 - hole for the union; 6

- external formwork.

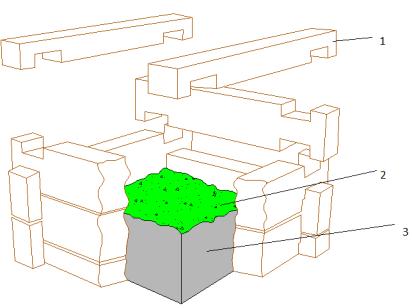

After analyzing all the

existing lining, we offer individual wood-concrete combined mining support with

adjustable load-bearing capacity, the possibility of failure and the clearing

mechanized transport complex (Figure 4). The technical result of the invention

is to increase the carrying capacity of the lining with the possibility of its

destruction and transportation of the clearing mechanized complex. This

technical result is achieved by the fact that, in the process of construction

of the individual roof supports, which includes the construction of a wooden

formwork zavodka plastic insulation inside the fire, fill a plastic bag with a

mixture of concrete. Wooden decking

is structural, its elements are made of timber with slots for quick assembly in mining conditions, the plastic insulation is made of dense

bag to fill the entire inner space of the wooden formwork, plastic bag filled with a solid malleable composition.

Mining support with adjustable load capacity, has the ability to transport and destruction of the clearing mechanized complex. Distinguishing characteristics

of the prototype lies

in the fact that the plastic bag

has an arbitrary shape, it is not filled with air, after setting hardening material (concrete) plastic bag is not recovered,

the wooden formwork is structural, destroys combine.

Figure 4. Individual

composite wood-concrete

rock bolting with

an adjustable load-bearing capacity

1 - Structural

wooden formwork; 2

- hardening solution; 3 - a plastic bag.

Using as a

stationary formwork lining

structural wood fire,

geotextiles, sliding plastic pipes can get a

wide range of strength and deformation

characteristics of stationary lining

installed in the dismantling chamber

and reduce the likelihood of accidents during demolition

work.

Thus, research on

the experience of entering into a

pre-prepared OMC dismantling

development in Kuzbass

mines and the world have shown that the standard methods of attachment dismantling mines in Kuzbass mines do

not meet modern trends of development of assembly and dismantling.

Studies have shown that

emergency cases are

related to insufficient fastening very weak roof bolting, and insufficient assessment of the role of the stationary

lining located in the development of (coal pillars, bonfires,

ores. Rack).

On the basis

of studies proposed improved

design of fixed lining,

reduces the risk of roof collapse and

accidents UMC at the entrance to

a pre-prepared production of the

dismantling, due to a high load

capacity and variable compliance. Using structural

elements increases manufacturability

and ease of installation of roof support in mine

conditions. The ability to combine

the destruction of the lining makes it easy to dismantle the stationary lining at

the entrance and provides

transportation of destroyed parts

of the lining of the mine conveyor network.

Bibliography:

1. Патент номер 2381367(13) С1 «Костровая крепь»

2. Патент номер 2472933(13) С1 «Тумба для поддержания повторно используемых подготовительных выработок»

3. патент номер 2079665(13) С1 «Костёр для охраны выемочных выработок»