Технические науки/ Авиация и космонавтика

Dr Nickolay Zosimovych

University of South Wales, Pontypridd, UK

STRUCTURAL AND PARAMETRIC

OPTIMIZATION FOR FLIGHT VEHICLE STRUCTURES

Keywords: Parametric optimization (PO), technical system (TS), flying vehicle (FV),

design and development (D&D), structural optimization (SO), structure

diagram (SD), engineering design solutions (EDS), airframe, structural modules

(SM), essential features (EF), matrix, unmanned flying vehicle (UFV).

I. Introduction. The parametric

optimization (PO) methods enabling us to determine the optimal values of the

technical system (TS) parameters for a specified structure have been well

developed to date and successfully applied.

Besides optimization of parameters of the designed unit, considerable

attention of scientists and practical specialists is attracted to the problem

of synthesis of its structure [1-4]. This problem is very important and

fundamental, as it is virtually impossible to develop a unit with an

ill-conceived and ill-founded structure to a rational design level [5-7]. In

its turn, the flying vehicle (FV) structure influences the efficiency of TS [8].

In order to improve technical and economic parameters of the designed product,

design and development (D&D) shall be conducted in three stages [4, 9-10].

Specific types of problems shall be solved at each stage.

II. Principles of Design Objects Decomposition. Problems

of the first type are the problems of choosing or finding the most effective

physical principle of functioning under specified conditions and requirements.

In aviation and rocketry, these problems are solved at the stage of general or

external design of the flying vehicle. This stage shall result in establishment

of a combination of physical and geometrical characteristics, guiding a

conceptual design of the flying vehicle. They shall be as well initial data for

the next structural design stage solving the problems of the second type. It

should be understood that the structural design and designing are not synonyms and

are hierarchically interrelated separate stages of design and development

(D&D) [1, 4, 12].

The

second-type problems are the problems of selection or searching for the most

efficient technical solution, when physical operating principle has been specified.

Problems of the second type are sometimes referred to as problems of structural

optimization (SO). The flying vehicle structure usually means its structure

diagram (SD) governed by design features. However, SD ambiguously conditions

technical solutions [9]. A technical solution shall be predetermined both by

design and technological characteristics. When selecting and validating an

efficient technical solution, you should optimize its adaptability to

streamlined manufacture [5]. So, FV structure design stage must result in a

reasonable choice of engineering design solutions (EDS). Hereinafter, EDS shall

mean a structure clearly conditioning the technical solution. The problems of

searching rational structures belong to the class of inverse problems. To solve

the direct problems we are to study the predetermined structure of an object

and determine its physical condition while in order to solve inverse problems

we are to synthesize the structure of an object that optimally implements the

required physical condition. These

problems are not subject to full formalization, since complete set of

requirements for EDS cannot be formalized. It is difficult for example to

formalize the requirement of adaptability, ease of operation, etc. In these

conditions it is necessary to develop systems of models which should simulate

FV function and the designer dialogue with the simulated models. These problems

are rather scientific than technical ones [1].

The

detailed EDS elaboration to the level corresponding to the execution plan shall

be done at the design stage while solving problems of the third type. The

designing purpose is materialization of EDS.

The

third type of problems includes problems of determining the optimum design and

technical parameters for the given technical solution. The result from solving

these problems in the design stage shall be a set of design, engineering,

technical and other documents required by the standards.

The

hierarchical structure of D&D problems becomes apparent with a possibility

of step-by-step solution. It demonstrates that problems may be not merely split

into simpler ones but also that there are qualitative changes in the problems

occurring during transition between one stage and the next one. Another feature

of the hierarchical structure is a close relationship between designed

subsystems. It does not allow completing the design in one cycle, and makes it

necessary to build an iterative design process.

Apparently

each D&D stage is characterized by its own level of structure development.

If we present the airframe structure of FV as a tree graph with the entire set

of detailed structural features [13], then iterative design procedure will turn

dimensionality problem into what Bellman called "curse of

dimensionality" [1, 4].

Under

these conditions, the solution of problems at any design stage encounter two

difficulties [1, 13]:

1)

there are too many variables; for FV

the vector dimensions are to be within 103…106;

2)

structural variables at different

levels influence the functional properties of the structure too differently,

which certainly results in a large number of inefficient search steps.

Therefore,

it is necessary to have harmonized decomposition design problem schemes and

design object structures.

Creation of harmonized decomposition schemes for object structures and

design problems reduces the dimensionality problem and allows us to choose the

structure and characteristics of load-bearing units not only from the

standpoint of efficiency of the units, as it often happens in practice, but

also considering their joint operation in the designed flight vehicle. This

should significantly increase the efficiency of EDS due to reduction of time,

cost and complexity of experimental testing of flight vehicle’s design

elements. In order design tests could be verification of the design, rather

than an improvement means, you must submit to the tests a design implementing a

reasonable technical solution [14].

III. Decomposition of Flight Vehicle Structures. Let’s define the structure of TS and

formalize it in relation to the subject area of research, i.e. FV

[8, 15, 16].

From the engineering point of view different structures of TS under

consideration differ from each other by the number of elements, the elements

themselves and the method connecting these elements. From the mathematical

point of view, there are different PO problems for different structures. If you can’t specify same sets of optimized parameters, the same objective functions and

limits when stating PO problems for

two TS versions, these TS versions have different structures [7, 11]. It is

easy to note that this definition of the structure does not contradict the

engineering sense. Let’s describe this concept, based upon the information

about the product contained in the structure.

The

structure of the product determines its properties, which ensure operation of

the product with high reliability, and which may be provided to it during the

manufacturing process. This definition general for TS applies as well to the

concept of flying vehicle structures but requires more detailed consideration.

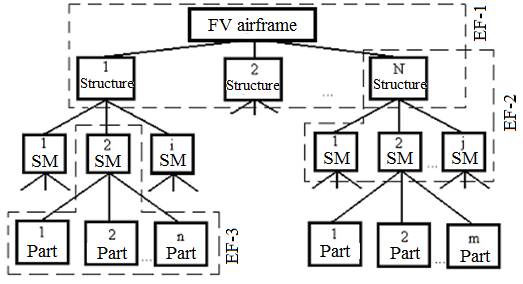

Fig.

1. Functional and constructional modules of structures included into FV

airframe

When

we design the structure of a flying vehicle airframe, we deal with a complex TS

hierarchically subdivided into simpler assembly units [13]. So, for example

airframe functionally and structurally consists from several FV structures,

which in their turn are subdivided into units – structural modules (SM), and

each of the lower-level units consists of technologically inseparable parts (Fig.

1) [16].

The

assembly units are products with their specific functional properties. It means

they have their own structures implementing these properties. Obviously, the

principle of structure decomposition must be general for all levels of scheme

decomposition (see Fig. 1). It should bring in line common design and

engineering laws specific for FV airframe design with the functional properties

of the structure at each decomposition level.

The

suggested decomposition of FV structures is based on the principle of

identification of the essential features (EF) in the structure, and their

localization at each level of the decomposition scheme [3, 4, 13]. The idea to

identify the essential TS features and to establish the relationship between

them can significantly accelerate finding the best solution in order to improve

the quality of the design process itself [7, 10, 17].

Table 1

Matrix for essential feature groups according to their

influence upon different functional characteristics of the object

|

Level of study |

TS function |

Performance capabilities |

||

|

FV airframe |

units |

SM |

||

|

1 |

|

|

|

|

|

2 |

|

|

|

|

|

3 |

|

|

|

|

|

4 |

|

|

|

|

We

can establish several groups of EF as relates their influence on the various

functional properties of the object (Table 1.) in the structure of assembly

units for airframe of an unmanned flying vehicle (UFV) [1, 13]. These properties should include [18]:

·

functioning of the object as TS with

well-defined tasks;

·

functioning (performance

capabilities) of the object and its constituent elements under the influence of

the environment.

Table

1 [13, 16, 19] represents a triangular SM

matrix. The main elements of the matrix (![]() ), which represent a group of EF, which is established during the analysis

of the relevant functional design properties are to be found at the

intersection of lines (levels of study) and columns (functional properties).

All the structural features designated in the columns represent the structure

at the referred level of study.

), which represent a group of EF, which is established during the analysis

of the relevant functional design properties are to be found at the

intersection of lines (levels of study) and columns (functional properties).

All the structural features designated in the columns represent the structure

at the referred level of study.

Structural

features are generalized structural parameters hierarchically adjusted

according to decomposition levels with progressive detailed elaboration to the level corresponding to the design

concept. At each level of the structure decomposition we can identify three

groups of structural features [1, 3, 18]:

1)

physical and mechanical

characteristics of construction materials;

2)

geometric parameters with

technological and operational limitations;

3) mass and inertial characteristics.

Hence,

the structure at each ![]() level of decomposition scheme will be

determined by three sets of parameters [14, 16]:

level of decomposition scheme will be

determined by three sets of parameters [14, 16]:

![]()

The

first group ![]() is parameters, which are invariable during

the analysis and synthesis of the structure. The second group

is parameters, which are invariable during

the analysis and synthesis of the structure. The second group![]() are the geometric parameters variable

within the prescribed limits:

are the geometric parameters variable

within the prescribed limits:

![]()

where

![]() and

and ![]() are the minimum and the maximum

values determined based on technical and operational conditions.

are the minimum and the maximum

values determined based on technical and operational conditions.

Table 2

Topology levels of structure development

|

Structure decomposition level |

Complex of varying characteristics |

Decomposition of structure topology |

|

1 |

|

External

topology of FV structures |

|

2 |

|

Internal

topology of FV structures |

|

3 |

|

External

SM topology |

|

4 |

|

Internal

SM topology |

Table 3

Formalization of the structure

decomposition of FV structures

|

Structure decomposition level |

Structure decomposition of FV structures |

|

1 |

|

|

2 |

|

|

3 |

|

|

4 |

|

The

third group![]() are the parameters derived from the first and

the second groups. All the varying characteristics at the structural levels

represent the level of development of the structure topology. (Table 2) [12, 14, 18].

are the parameters derived from the first and

the second groups. All the varying characteristics at the structural levels

represent the level of development of the structure topology. (Table 2) [12, 14, 18].

So, if

we summarize the above and complement definition of the structure with a

requirement of the minimum FV weight requirement, it will be possible to give a

definition of the structure general all levels of decomposition [18, 19]. The FV structure consists of a set of

structural features (providing the structure with physical, mechanical,

technical and operational properties), which will ensure a highly reliable

operation of the designed unit, conditioned upon minimum weight of the FV [8,

13].

The

above analysis of structural components according to their influence on the

functional properties of the FV, allows us to formalize the structure

decomposition of FV structures (Table 3) [3, 16, 18].

Conclusion. Thus,

the structure decomposition of FV structures is based upon identification of

essential features that reflect the specific structural and technical patterns

for structure formation and adjustment with specific functional properties of

FV [13, 19]. Such structure decomposition is

not an artificial device decreasing dimensions. It is caused by the difference

in operational requirements for the airframe in general, its units and

structural modules. For example, if the requirements for strength and stability

of the SM, which make up the structural units (compartment housing, the bearing

surface), are fulfilled, there will remain the problem of overall stability

(static and dynamic) of the FV structures.

At the same time, operability of units is a necessary but not sufficient

condition for the FV airframe operation, since implementation of the

operational requirements for the design of the FV in general associated with

harmonization of the elastic behavior, mass and inertial properties of the

units.

References

1. Голубев И.С., Андреев В.В., Парафесь

С.Г. Методы структурно-параметрической оптимизации силовых авиационных

конструкций: Учеб. пособие. – М.: Изд-во МАИ, 1991. – 68 с.

2. Зосимович Н.В. Декомпозиция задач синтеза структуры силовых

конструкций ДПЛА для оперативного природоресурсного и

экологического мониторинга окружающей среды // Cборник научных трудов по материалам научно-практической

конференции «Научные исследования и их практическое применение. Современное

состояние и пути развития», 1-15 октября

3. Первозванский А.А., Гайцгори

В.Г. Декомпозиция, агрегирование и приближенная оптимизация. М.: Наука,

1979.

4. Лось Л.В. Теория структуры

конструкций технологичных машин и приборов. – Житомир:. Житом. сельскохоз. ин-т, 1991. – 167 с.: ил.

5. Бирюк

В.И., Липин Е.К., Фролов В.М. Методы проектирования рациональных конструкций ЛА // Труды ЦАГИ, № 1776, 1976.

6. Ланцош К. Практические методы прикладного анализа. М.: Физматгиз, 1961.

7. Валуев

М.И., Харченко В.П., Яппаров А.Н. Системотехніка

та основи проектування аеронавігаційних систем: Навч. Посіб. – К.: НАУ, 2003. – 120 с.

8. Беспилотники /

Аэрокосмический вестник. – 2005. - № 8.

– К.: ООО «СПЕЙС-ИНФОРМ», с. 32-33.

9. Половинкин А.И., Бобков Н.К., Бум Г.Я. Автоматизация

поискового конструирования. – М.: Радио и связь, 1981.

10. Половинкин А.И. Автоматизированные системы поискового

конструирования // Материалы І Всесоюзного совещания по

автоматизации проектирования в машиностроении. АН БССР, Минск, 1978.

11. Дитрих

Я. Проектирование и конструирование. Системный подход. – М.: Мир, 1981.

12. Вязгин В.А.,

Федоров В.В. Математические методы автоматизированного проектирования. М.: Высш. шк., 1989.

13. Зосимович Н.В. Структурно-параметрическая оптимизация

силовых конструкций дистанционно-пилотируемых летательных аппаратов

оперативного природоресурсного и экологического

мониторинга окружающей среды //

Региональный вестник молодых ученых. М.: Academa, 2005.- №3.- C. 97-98.

14. http://www.mai.ru/conf/aerospace/internetconf/

- Парафесь С.Г. Использование математического аппарата

идентификации конструкций в задачах проектирования летательных аппаратов // Интернет-конференция

"Авиация и космонавтика-2007"

15. Зосимович

Н.В. Методика решения декомпозиционных задач синтеза

структуры силовых конструкций ДПЛА для оперативного природоресурсного

и экологического мониторинга окружающей среды // II

Международная периодическая научно-практическая конференция «Альянс наук:

ученый – ученому», 3-7 октября

16. Зосімович М.В. Структурно-параметрична

оптимізація силових конструкцій дистанційно-пілотованих літальних апаратів для

оперативного природоресурсного та екологічного

моніторингу довкілля // Вісник Національного авіаційного університету. - № 3-4

(33). – К.: НАУ, 2007. – С. 127-132.

17. Левин

Г.М., Токаев В.С. Декомпозиционные методы оптимизации

проектных решений. – Минск: Наука и техника, 1978.

18. Зосимович Н.В. Задача декомпозиции структуры силовых

конструкций ДПЛА для природоресурсного и

экологического мониторинга окружающей среды //

Матеріали VIIІ Міжнародної науково-практичної конференції

“Наука і освіта’2005”, 20-30 червня 2005 р. Том 53: Технічні

науки. Дніпропетровськ: Наука і освіта, 2005.- C.14-17.

19. Зосимович Н.В. Математические основы проектирования ДПЛА

экологического назначения // Стратегія розвитку України, К.: НАУ, 2006.

- № 5.– C. 218-222.