Tagiev Sanan Mehman oglu

Kuzbass State Technical University, Kemerovo

Technologies for the Conversion of Biomass to Liquid

Transportation Fuels

Cellulosic

biofuels have been proposed as part of the solution to climate change and the

dependence on fossil fuels, not only because they can be produced domestically

from a variety of renewable biomass feedstocks, but also because they can

reduce the greenhouse gas emissions, since the carbon dioxide captured when the

feedstock crops are grown and cultivated balances the carbon dioxide released

when the fuels are burned. According to the Energy Information Administration,

biofuel consumption in primary markets is expected to reach 20% of renewable

energy sources by 2030. Although corn ethanol has led the adoption of renewable

biofuels in the transportation industry, the Renewable Fuels Standard (RFS),

part of the Energy Independence and Security Act of 2007establishes a target of

36 billion gallons of renewable fuels by 2022 with cellulosic biofuels

contributing more (16 billion gallons) than corn ethanol (15 billion gallons).

Biomass-to-liquids (BTL) technology, which converts cellulosic biomass to liquid

transportation fuels, has been considered a promising approach for overcoming

the market barrier resulting from the current vehicle technology and fuel

distribution infrastructure [1].

The

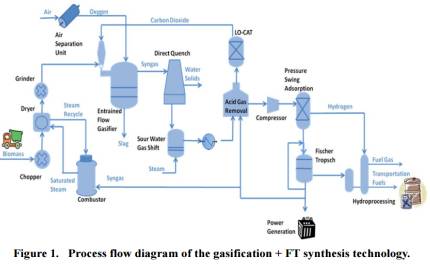

two major technologies reviewed here are gasification followed by Fischer-Tropsch

synthesis and fast pyrolysis followed by hydroprocessing.

Gasification

followed by FT synthesis

The

gasification technology produces transportation fuels through Fischer-Tropsch

synthesis with electricity as byproduct. There exist two techniques of

gasification: an oxygen-fed, low-temperature (870°C), nonslagging, fluidized

bed gasifier and an oxygen-fed, high-temperature (1300°C), slagging, entrained

flow gasifier. Both gasifiers are followed by Fischer-Tropsch synthesis, which

involves converting carbon monoxide and hydrogen into liquid hydrocarbons. The

major operational steps of this conversion technology are preprocessing,

gasification, syngas cleaning, fuel synthesis, hydroprocessing, power

generation, and air separation.

Biomass feedstocks are first dried to reduce the particle sizes during

pretreatment. Each gasifier requires a specific particle size. The

low-temperature (LT) option can handle larger feedstock size of 6 mm, whereas

the high temperature (HT) option requires a smaller feedstock size of 1 mm.

Low-temperature gasification also has the advantages of lower capital cost and

high heat transfer rates within fluidized bed; but it has lower thermal and

carbon efficiency. High-temperature gasification has advantages of higher

carbon conversion, low tar, and methane content [2].

Biomass feedstocks are first dried to reduce the particle sizes during

pretreatment. Each gasifier requires a specific particle size. The

low-temperature (LT) option can handle larger feedstock size of 6 mm, whereas

the high temperature (HT) option requires a smaller feedstock size of 1 mm.

Low-temperature gasification also has the advantages of lower capital cost and

high heat transfer rates within fluidized bed; but it has lower thermal and

carbon efficiency. High-temperature gasification has advantages of higher

carbon conversion, low tar, and methane content [2].

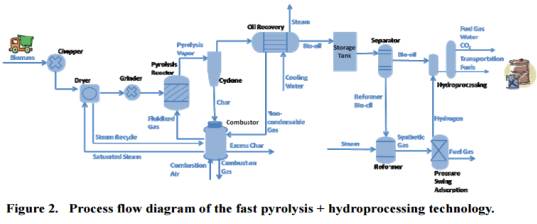

Fast

pyrolysis followed by hydroprocessing

Fast

pyrolysis is a process of heating biomass without oxygen that converts

feedstock into gaseous, liquid, and solid products. Its processing steps

include biomass pretreatment, fast pyrolysis, solids removal, oil recovery,

char combustion, and hydroprocessing. Biomass feedstocks are dried to around 7%

moisture content, and particle size is reduced to diameter of 3 mm during

pretreatment. The dried biomass is then fed into a fluid bed pyrolyzer

operating at 480°C and atmospheric pressure. Pyrolysis vapors enter a cyclone,

which separates solids and vapors. The vapors are then condensed in an indirect

heat exchanger that yields bio-oil. Noncondensable gases and solids from the

pyrolysis reaction are sent to a combustor to produce the required heat for the

drying and pyrolysis processes. Bio-oil is collected in a storage tank that

acts as a buffer to the upgrading process [3].

The

hydroprocessing step involves hydrotreating and hydrocracking. Hydrotreating is

an exothermic process that removes undesired compounds such as oxygen in

bio-oil. Hydrocracking is a process that breaks down larger molecules into

naphtha and diesel. During hydrotreating, hydrogen can be provided from outside

source or can be extracted from the bio-oil. Around one-third of the bio-oil is

needed to produce the required amount of hydrogen in the hydrogen production

scenario. Separator, reformer, and pressure swing adsorption are needed before

hydroprocessing. A gravity separator separates pyrolysis lignin from the

water-soluble bio-oil. Aqueous bio-oil and steam are sent to a high-temperature

reformer, which produces syngas. This syngas is fed with methane into a

pressure swing adsorption reactor to produce hydrogen. In the end, bio-oil is

converted into transportation fuels via hydroprocessing [4].

The

results of the implementation report show the potential of BTL in detail. A

considerable amount of fuel can be produced with feasible technologies, thus

making an important contribution to the security of supply. BTL also has a high

potential to reduce carbon dioxide emissions. To exploit these possibilities, further

steps by industry and the state are required. The company is responsible for

the economic risk when assessing its decisions on how far to go in the

development and production of BTL. Today, the cost of BTL production, which is

higher than that of conventional fuels, is of great importance here. If

large-scale BTL production is to be made economically competitive with

first-generation biofuels, the optimization potential identified needs to be

exploited. Industry and investors will have to provide the necessary capital;

government investment grants and guarantees are also required for the first

plants. Reliable legal and political parameters are also of prime importance.

Cooperation and networking between all of the players involved - agriculture

and forest management, investors, operators, and the petroleum and automotive

industries - will be both beneficial and expedient. Reliance is placed on

market mechanisms for the long-term and cheap provision of biomass. The

producers must be shown the perspectives related to this and provided with

incentives to achieve attractive yields  with suitable plant crops.

with suitable plant crops.

Bibliography:

1. Biomass as Feedstock for a Bioenergy and Bioproducts

Industry: The Technical Feasibility of a Billion-Ton Annual Supply; U.S. Department of Agriculture and U.S. Department of Energy:

2005.

2. Biomass Program Multi-Year Program Plan 2010; U.S. Department of Energy:

Office of Energy Efficiency and Renewable Energy: 2010.

3. Roadmap for Biomass Technologies in the United States; U.S. Department

of Energy: Biomass Research and Development Initiative: 2007.

4. National Biofuels Action Plan; Biomass Research and Development Board:

U.S. Department of Agriculture and U.S. Department of Energy: 2010.