D. Yermukhamed

al-Farabi Kazakh National University, Almaty,

Kazakhstan

Formation of the thin layers of

organometal perovskites by vacuum evaporation method for application in solar

cells

Nowadays the subject of attention

from specialists in the field of solar energy become materials, which called

perovskites. During the short time we obtained solar cells with coefficient of

performance (COP) of 3.8% in 2009 to 20.29% in 2015. World began to talk about

the remarkable success of CH3NH3PbX3 organometallic

threehalogen perovskites (where X - I, Br, Cl halogens, or their mixtures), and

about perovskite photovoltaics era. With this material began to have great

expectations for the development of highly efficient solar cells with cost much

lower (4-6 times) than cost of elements based on crystalline silicon, which is

basic material of modern photovoltaics.

It should be noted that the creation

of perovskite solar cells was observed by «Science» journal, as one of the

technical achievements of 2013. Perovskite solar cells manufacturing do not

require expensive clean rooms and technological equipment, and materials.

Formation of perovskite material required temperature that do not exceeding 150

° C.

In this article represented results

on the formation of perovskite layers by different vapor phase methods. In

vapor phase method organic part is treated by vapour of inorganic part; it is a

method of perovskite layers formation with wide band gap, which provides method

of producing CH3NH3PbBr3 wide-perovskite. This

perovskite may be used to create cascade solar cells, as frontal heterojunction element.

In this experimental work used vacuum evaporation methods such as vapor

deposition with dual source and deposition by vapour assisted solution process

to produce organometallic perovskites.

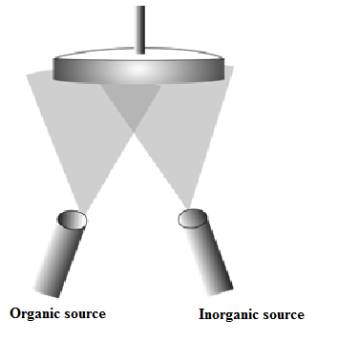

During vapor deposition with double source, we put in separate crucibles

500 mg CH3NH3I and 100 mg PbCl2. Substrate

fixed on substrate holder, which disposed above sources with FTO coated TiO2

converted down to the sources. After evacuating of pressure in chamber to 10-5 mbar, two sources were

heated slightly above the desired deposition temperature for 5 minutes (CH3NH3I

heated to 120 ° C, and PbCl2 to 325 ° C) to remove volatile

impurities before material deposition on substrate. The substrate holder

rotated for uniform deposition of coating, because the right source

predominantly covers the right side of substrate, which is similar to the left

source. The substrate holder cooled by water at about 21 ° C, although the

precise measurement of substrate temperature during the deposition process was

not carried out.

In Figure 1 schematically illustrated system of deposition with dual

source.

Figure 1 - Schematic image of

deposition system of materials. Thermal evaporation system with dual source for

deposition of perovskite absorber; organic source - methylammonium iodide and

inorganic source - lead chloride

Perovskite films have been optimized for improved device performance [1]

by applying the changes in key parameters such as speed and deposition time for

two sources. In particular, the performance of device [2] is very dependent on

the ratio of CH3NH3I to PbCl2 content, and the

total deposition thickness.

Perovskite films obtained by vapor deposition with dual source were

homogeneous [3]. Vapor deposition can lead to fully optimize the electronic

contact on the borders through

plurality of layers with controlled doping levels.

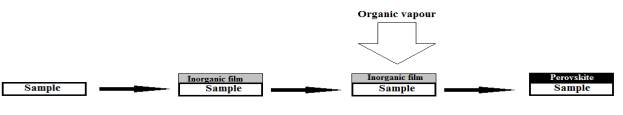

The following method which was used for manufacturing the organic /

inorganic hybrid perovskite films – is a deposition by vapour assisted solution

process. In this method, inorganic film structures is formed by depositing

precursor solution onto substrate, followed by treatment with vapors of

necessary organic compounds [4]. PbI2 and CH3NH3I

- corresponding vapours of precursors that form CH3NH3PbI3.

PbI2 films deposited on the FTO glass coated by compact and

mesoporous TiO2 layer, followed by annealing in CH3NH3

vapour at 150 ° C under nitrogen atmosphere for 2 hours to form perovskite

films (CH3NH3PbI3).

In Figure 2 represented schematic image of perovskite film forming by

vapour assisted solution process.

Figure 2 - Schematic image of the

formation of perovskite film with vapour assisted solution process

Vapour assisted solution process method is a low-temperature method for

production of perovskite films based on kinetically favorable reactions between

the newly deposited PbI2 film and CH3NH3I

vapour [5].

A key step in this method is the growth of film during the direct

reaction of just deposited PbI2 film with CH3NH3I

vapor phase. It uses kinetic reactivity of CH3NH3I and

thermodynamic stability of perovskite during the immediate growth of film; in

the result produced films with well

defined grain structure with grain size of several microns, with complete coverage

of the surface and small surface roughness of surface suitable for photovoltaic

applications.

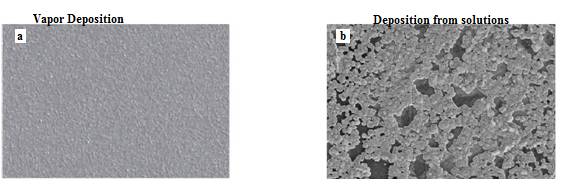

In Figure 3 shown SEM images of films surface prepared from the solution

and by vapor-phase method. The films deposited from vapor is extremely

homogeneous. In contrast, the films treated in the solution, covered partially

the substrate with crystalline islands on tens of micrometers of scale length.

Voids between crystals in the film treated in solution apparently reach

directly glass coated by compact TiO2 and FTO. Perovskite film,

deposited from vapour, is uniform and similar to the FTO layer with a little

more crystallinity in appearance. Perovskite film obtained from solution, has

an extremely smooth surface, in accordance with the larger size of crystalline

particles.

Figure 3 - Characteristics of the

topology of thin films. SEM images of the surface (a) perovskite films

deposited from vapour and (b) perovskite film treated in the solution

Perovskite film obtained by deposition by vapour assisted solution

process method have full coverage of the surface, uniform grain structure with

a grain size of more than micron and

100% conversion of the precursor. Rebuilding of PbI2 film during the

implementation of CH3NH3I conditioned by decreasing

energy of grain boundaries. Vapour assisted solution process method is simple,

manageable and universal method in an effort to achieve high quality of

perovskite films, and therefore, photovoltaic devices with high efficiency. The

inclusion of organic compounds in the deposited inorganic structures by vapour

effectively prevents from a high rate of reaction (formation) of perovskite

during coprecipitate precursor, and also eliminates the possibility of film

deterioration which sometimes observed during the immersion of inorganic

structure to solution with organic compounds.

The roughness of film produced by vapour assisted solution process

method is small. The resulting film has thickness of about 350 nm, with

distinct grains across the whole thickness of film. 100% surface coverage,

microscale grain size and uniform grain structure make this prepared film

promising to use in photovoltaic devices. These characteristics may be

associated with relative smoothness of PbI2 films.

1. Were carried out research works on the formation of perovskite films

by vapor deposition methods with a dual source and deposition by vapour

assisted solution process.

2. We used three-layer version of the front contact consisting of FTO

layers, blocking and mesoporous TiO2 layers. Blocking TiO2

layer prevents entering of holes to the FTO. Photoconverters based on

mesoporous have several advantages over the planar devices such as higher

efficiency, less hysteresis effect.

3. Using the methods of scanning microscopy were

studied structural properties and determined the thickness of perovskite layer.

In work was found optimal deposition regimes, under which formed perovskite

thin layers.

4. Considering methods show that can get

organometallic perovskites films with high-quality for further practical

application in solar cells and lasers. Another advantage of metal halide

perovskite lasers is their frequency tuning in the visible range. This can be

easily achieved through the replacement of iodide ions by bromide.

5. Based on the experimental data one can conclude

that the obtained films is not inferior to known literature methods and are

suitable for use in photovoltaic devices.

Literature:

1.

Lee,

M. M., Teuscher, J., Miyasaka, T., Murakami, T. N. & Snaith, H. J.

Efficient hybrid solar cells based on meso-superstructured organometal halide

perovskites. Science 338,643–647 (2012).

2.

Ball,

J. M., Lee, M. M., Hey, A. & Snaith, H. J. Low-temperature processed

meso-superstructured to thin-film perovskite solar cells. Energy Environ. Sci.

6, 1739–1743 (2013).

3.

Liu M., Johnston M. B., Snaith H. J. Efficient planar

heterojunction perovskite solar cells by vapour deposition //Nature. – 2013. –

Vol. 501. – №. 7467. – P. 395-398.

4.

Chen

Q. et al. Planar heterojunction perovskite solar cells via vapor-assisted

solution process //Journal of the American Chemical Society. – 2013. – Vol.

136. – №. 2. – P. 622-625.

5.

K.

Liang, D. B. Mitzi and M. T. Prikas, Synthesis and Characterization of

Organic-Inorganic Perovskite Thin Films Prepared Using a Versatile Two-Step

Dipping Technique, Chem. Mater., 1998, 10, 403–411.

Резюме

В этой работе рассматривается получение пленок перовскита

с помощью методов вакуумного

испарения. А именно

методами, парофазного осаждения с двойным источником и осаждения обработкой из раствора индуцированное паром.

Были

определены преимущества и

недостатки данных экспериментальных методов. Были исследованы структурные

свойства пленок с помощью

сканирующего электронного микроскопа. Были

найдены оптимальные режимы осаждения тонких слоев перовскита.

Ключевые слова:

органометаллический перовскит, парофазное осаждения с двойным источником, осаждение обработкой из раствора

индуцированное паром, СЭМ изображение.