Agriculture/2. Mechanization of

agriculture

Tumanova M.I.

Kuban state agrarian University named

after I. T. Trubilin, Russia

On the question of working machines

grinding bodies roughage in compressed form

In order to successfully address the problem of development of animal

husbandry, which is of strategic importance for food security of the country,

need to strengthen the fodder base. Widely introduce progressive methods of

harvesting, allowing in the shortest possible time to carry out the cleaning of

forage crops and get a high-quality forage. Corn is superior to all

other crops in terms of yield and fodder advantages. It is widely used as food

and raw materials in many industries, from its green mass produce high-quality

feed [1,2,7].

Avoid loss of feed at reaping,

transportation, storage and use. It is necessary to attract the required number

of units of foraging techniques and create the conditions for its smooth

operation.

According to information provided by the Ministry of Agriculture and

Processing Industry of Krasnodar Region, in 2016 farmers Kuban exceeded the

plan for preparation of feed for livestock. As a result, in the Krasnodar

region harvested more than 1.5 mln. Tons of silage, which is 103% of the plan,

and 314.9 thous. Tons of hay (118% of plan). This would allow for wintering

cattle at a high level and perform tasks for the production of animal products .

In livestock need the technology and equipment, which significantly

reduces the need for people, energy and material resources, and at the same

time make it possible to increase the production of livestock products.

The determination of the conditions and modes of working machines, in which the

destruction of the processed food particles will be possible with the least expenditure

of energy and is in most cases the main purpose of research [5,6].

The determination of the conditions and modes of working machines, in

which the destruction of the processed food particles will be possible with the

least expenditure of energy and is in most cases the main purpose of research .

Mobile and fixed pins chopper roughage IGK-5, passing through the feed

itself, breaking the stalks, tearing them and crushed. stalk chopping length

can be adjusted by means of drive gears mounted on the conveyor drive - feeder.

The working body Tomakawk 5050 -

a rotor, which is suitable for the treatment of wet silage bales, for the

treatment of hay and root crops as well as for crushing and spreading straw in

pens at besstoylovom content. The grinding system is represented by a set of

blades on the rotor. triangular-shaped blades tear the bale. Long blade milled

material. The rotor provides constant dispensing rate even when processing wet

material.

Twin-screw design of working bodies with grinding blades of the

mixer-distributor-feed shredder ISRK-12 "Master" allows quality to

grind and mix the components of long-fiber feed. Gearbox drive has 2 stages,

which allows you to select optimum performance for different types of feed.

Equipped with autonomous hydraulic system. Availability weight device allows

control of the mass of the loaded wagon in the feed according to the diet.

Thus in a shredder rolls Uniball LUCLAR chopping rotor is made as a disc

with a diameter exceeding the diameter of the roll on which the knives are

interchangeable. Disc straw chopper rolls is more efficient in comparison with

the drum, as it provides a uniform grinding material without jerks. The length

of the particulate material fractions standard is 8 to 12 cm or 8.7 cm using rotor

power (with a large number of knives).

The main operating body in a shredder rolls IR-8 - chopper drum located

in front of the camera via knives mounted on it (blades) provides grinding

material. The discharge device has the ability to hydraulically vary the height

and distance of the ejection of crushed material.

Job feed rolls IRK-145 harvester is based on the organization of

counter-rotation in drum roll feed and cutter grinder, which is a disc with 8

blades, located at the bottom of the bottom of the drum. The roll is pressed

against the mill under its own weight, resulting in crushing the pressed mass

roughage. The crushed mass enters the cavity under the mill, gets on the rotor

blades of the impeller, under their action shall be made up and goes to the

unloading arm.

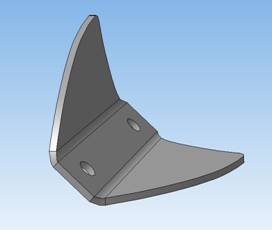

It is proposed to improve the shredders roughage installing cutting

segments (RF Patent №163827). The technical result of the proposed constructive

solution is achieved in that the cutting segment forage chopper, designed as a

blade composed of two planes disposed at an angle to each other and having an

arcuate cutting edge, the cutting segment plane are connected by fastening

elements to the working body, made in the form of rectangular plate with holes

to form a single piece, the plane of the blades set at an angle α to the

plane of mounting plate, and cutting edges formed arc outwardly planes.

It is proposed to improve the shredders roughage installing cutting

segments (RF Patent №163827). The technical result of the proposed constructive

solution is achieved in that the cutting segment forage chopper, designed as a

blade composed of two planes disposed at an angle to each other and having an

arcuate cutting edge, the cutting segment plane are connected by fastening

elements to the working body, made in the form of rectangular plate with holes

to form a single piece, the plane of the blades set at an angle α to the

plane of mounting plate, and cutting edges formed arc outwardly planes.

This design helps to improve feed milling quality due to the fact that

the material is cut in two planes, two-plane grinding arc segment profile [3,4].

Cutting forage harvester segment affects the feed material is as

follows. The feed to be ground, getting under the cutting edge of the blade

planes initially compacted to a certain limit, and then is cut.

When compaction occurs lateral feed force in a direction which coincides

with the side force occurring during cutting, thereby increasing the proportion

of the cutting and moving, as a consequence, reduction of energy consumption

for grinding feed. In view of undirected receipt of feed material is a material

impact on the planes of the cutting element in different directions

(omni-cutting).

The plate, made for fixing to the working body of work planes with

cutting edges, allows to increase the working surface of the cutting segment,

which increases productivity.

Literature:

1. Очистка початков кукурузы. Петунина И.А.

Монография / И. А. Петунина. Краснодар, 2005.

2. Обмолот початков кукурузы. Петунина И.А. Монография

/ И. А. Петунина. Краснодар, 2006.

3.

Фролов В.Ю. Измельчитель зерна сои в замоченном виде / Фролов В.Ю., Сысоев

Д.П., Горб С.С., Класнер Г.Г. // Эффективное животноводство. 2016. № 6 (127).

С. 22-23.

4.

Фролов В.Ю. Устройство для получения белковой суспензии из зерна бобовых

культур / Фролов В.Ю., Сысоев Д.П., Горб С.С., Класнер Г.Г. // Эффективное

животноводство. 2016. № 6 (127). С. 26-27.

6. Гаврилов М.Д. Раздатчик-измельчитель рулонной заготовки /

Гаврилов М.Д., Туманова М.И., Сысоев Д.П., Фролов В.Ю. // В сборнике: Научное

обеспечение агропромышленного комплекса Сборник статей по материалам IX

Всероссийской конференции молодых ученых. Ответственный за выпуск: А.Г. Кощаев.

2016. С. 330-331

7. Туманова М.И. Способы

уборки кукурузы на зерно / Туманова М.И. // Новая наука: Теоретический и

практический взгляд. 2016. № 3-1 (69). С. 37-39