Ermolaev V. A, Komarova N.A., Sosnina O.B.

The Kemerovo technological institute of the food

industry

Changes of a microstructure of products of an animal

origin in the course of freezing

Freezing

of a product is the most widespread method of conservation of a product, and

also the integral stage in many technological operations applied in the

food-processing industry at which in fabrics of a product there are the

essential physical and chemical changes reflected finally on its quality. Thus

distinguish the freezing occurring in separate freezing chambers and

self-freezing, occurring under vacuum as a result of tap of warmth by

evaporation at fall of temperature more low криоскопической

points and formations in a product of crystals of ice. Process of self-freezing

under vacuum is caused by intensive evaporation of a moisture in a product.

For

the majority of materials the most comprehensible is the method of

self-freezing that is caused by more uniform and fast cooling of a product on

all volume. Such a frost allows to avoid formation of large crystals of the ice

adversely operating on structure of fabrics of a product. Thus self-freezing is

favourable in the power plan.

Firm

cheeses on power and food value take a special place among foodstuff that is

caused by the high maintenance in them of fibers, dairy fat, vitamins and

mineral salts. Cheeses are a source of irreplaceable amino acids [1]. For

research of influence on a microstructure of cheese of freezing and

self-freezing in vacuum cheese "Dutch" was used. Preliminary a frost

of cheese it was made in the refrigerating chamber at temperature -40OC.

Self-freezing was carried out in the vacuum chamber.

|

|

|

|

a |

d |

|

|

|

|

b |

e |

|

|

|

|

c |

f |

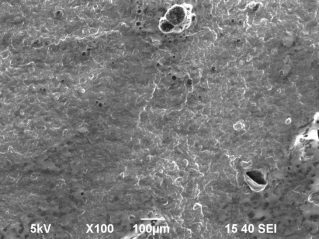

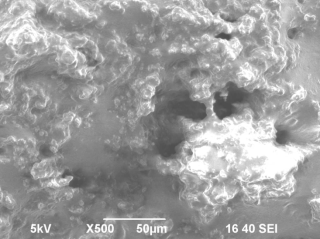

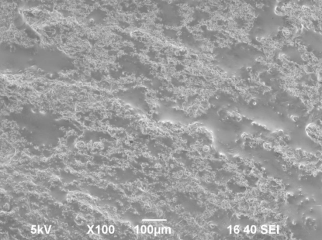

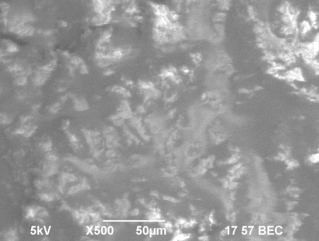

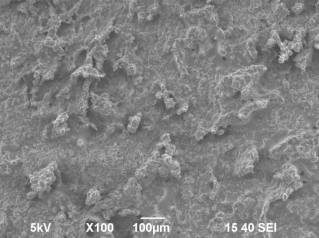

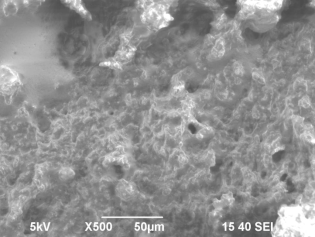

Fig.

1. A microstructure of the "Dutch" cheese: a, d - before frosts; b, e

- after self-frosts under vacuum; c, f - after frosts in the freezing chamber

On

fig. 1 cheese microphotos "Dutch" before and after frosts are

presented. After self-freezing cheese was characterized by an equal, smooth

surface (fig. 1 b, e) with characteristic cellular structure and capillaries,

the size 100 microns.

Formation

of crystals of ice in the course of self-freezing occurs by gradual deepening

of a zone of crystallization. A sign of end of process of self-freezing is

achievement in the middle of cheese particles of temperature-20 …-30OC.

Duration of self-freezing varies within 20-30 minutes. Increase of duration of

this process conducts to formation of too large crystals of ice that can be at

the bottom of destruction of cages of fabrics and deterioration of quality

indicators of the defrosted cheese.

At

fast freezing more uniform formation кристалликов

ice in cages and in intercellular space is observed. In a case with slow

freezing are formed кристаллики the large sizes, the cheese structure is thus broken, the surface

becomes rough with chaotic сколами (fig. 1 c, f). The

difference in distribution of crystals of ice at fast and slow freezing speaks

diffusion processes.

Thus,

on the basis of the spent experimental researches the expediency of application

of self-freezing under vacuum at which more uniform structure with small

crystals of ice in comparison with заморозкой

in the freezing chamber is observed has been established that directly affects

quality of cheese.

The

list of references:

1.

Majors, A.A. Formation of structurally-mechanical properties of cheese / А.А. Majors, Е.А. Nikolaev. – Barnaul, 2005. – 223 P.