Сельское хозяйство/ 4.Технологии хранения

и переработки сельскохозяйственной продукции

Kovalenko

S.A., Professor Poperechnyy A.N., senior lecturer Vlasova I.A.

Donetsk National

University of Economics and Trade named after M. Tugan-Baranovsky, Ukraine

Frying machine

for plant material

Today,

food industry and restaurant management widely use current lines, that processing

potatoes and vegetables. Main machine of these lines is the unit for frying

foods in oil. The most widespread both in Ukraine and abroad, received frying aggregates of continuous action, the

construction of which applied the same transporting organs like screw, belt and

stepper devices [1]. However, these structures inherent in the following

drawbacks:

1.

Fry-up occurs in deep fat, in large amount of fat with a significant product of

its absorption;

2.

Complexity of intensification frying process;

3.

Complexity of design;

4.

Large dimensions (length apparatus at 3-4 m);

5.

Relatively low quality finishing products due to mechanical impact that

transporting bodies and oxidation, when exposed to air.

The

utility model relates to apparatus for frying finely lumpy plant products and

can be used in the processing of plant material, such as frying potatoes,

eggplant, zucchini and more. The device for heat treatment of bulk food is the

most similar to utility model for technical essence [1, p. 204]. It consists of

two horizontal vibrating trays. Gutters are attached to the side wall by

hinges. Upper and lower troughs through eyelets and hinges combined with three

swivel rocker arm that middle hinge mounted to the support frame. Based on the

supporting frame under the lower chute placed eccentric cam drive working shaft

which is driven in rotation by V-belt transmission from the motor. Above

gutters on supporting frame mounted blocks infrared emitters with reflectors,

the distance from which the layer material can be changed. The device is

equipped with a hopper loading and unloading tray. After warming up the machine

for the operating mode activated vibratory drive which leads trays in

oscillatory motion.

However,

this unit has a number of drawbacks:

1)

large heat loss and high energy consumption in the process of frying;

2)

long duration of frying;

3)

the use of V-belt transmission and cam drive.

The

main objective utility model - a system that will reduce the frying and,

therefore, increase productivity, reduce energy costs for frying process and

improve operating conditions machine. Set object is achieved by the fact that frying

device that consists of a frame, body, hopper for loading two frying trays, extraction fan, infrared emitters, mounted on

trays Oil Injector, oscillatory movement trays provided magnetic vibrator in

establishing trays springs, body covered with insulation panels that snap doors

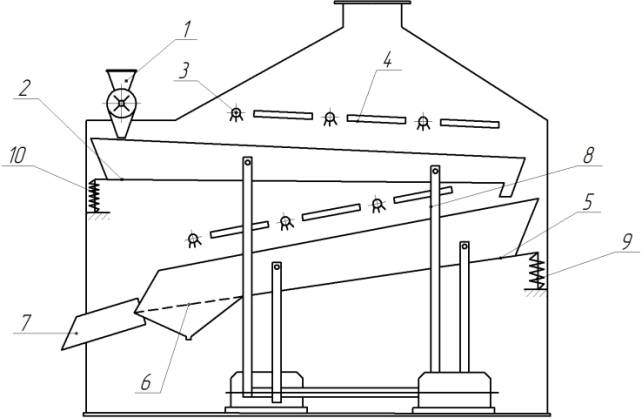

and observation windows. Frying machine shown in FIG. 1.

Figures

1. Frying machine

It

works as follows. Product using the boot device 1 reaches the vibrating tray 2,

which is mounted on springs 8. When transporting the product on oiled surface

is moistened with oil nozzle 3 which intensifies heat and prevents burning product

particles that act. Then the product moves under IR emitters 4, thanks to which

the process of frying. Speed is regulated by mechanisms 9 and 10,

which determine the angle trays 2. With increasing angle speed increases, so

changing the device's productivity and duration of frying. Getting on tray 5,

the product fried the other side. Frying temperature is 155-165 ° C. Excess oil

is removed by perforated bottom of the tray 6. Unloading product is due hopper

7.

The

design of the device has the following advantages:

1)

can reduce power consumption by summing the product of heat infrared radiation

and conductive heat from the walls of stalls;

2)

to speed up the process of frying due to more intensive heat supply and optimum

angle bins;

3)

simpler by changing the drive vibrator, which reduces its specific quantity of metal,

increases efficiency, facilitates assembly and disassembly issues, maintenance,

cleaning and repair.

Literature:

1.

Cherevko OI, Mikhailov, VM, Babkin IV Processes and equipment frying foods. Training. user / HDATOH

Kharkov, 2000 – P. 204 (Prototype).