UDC 538.9:621.785.6

INFLUENCE of hardening

temperature and holding time on the phase-structureCondition Springs of Cr-Ni

alloy

Mukazhanov Ye.B.1

Telebayev Ye.Ye.2

Takenova G.D.3

Tynaliev Bauyrzhan4

1 Doctoral

Student, PhD, Associate Professor, Academy of Economics and Law, Zhetysu State

University. I.Zhansugurov, Taldykorgan, Kazakhstan

Taldykorgan

Polytechnic College

2 Taldykorgan

Polytechnic College

3 PhD, Associate Professor, Taldykorgan Polytechnic College

4 Taldykorgan

Polytechnic College

Taldykorgan,

Kazakhstan

Shows a

two-phase structure of the alloy 47HNM after quenching in the range 900-13000S,

installed a crystalline structure, morphology, size and volume fraction of

particles allocated phases. It was found that with increasing heating temperature

increases the degree of homogeneity of the solid solution. The features of

changes in the structure of the alloy 47HNM depending on the temperature, the

holding time of heating for quenching, cooling rate.

Introduction

Spring precipitation-hardening

alloys - one of the most important classes of structural metallic materials,

which, depending on the purpose and the conditions of service of the elastic

elements of devices should have a wide variety of properties [1]. In operation,

the product of the spring alloys must have sufficient strength and elasticity

in static, cyclic and dynamic loading, and high resistance to small plastic

deformations. In addition, they must also meet the specific process

requirements, without which it is impossible to produce high quality elastic

elements of the devices specified configuration and get a set of high physical

and mechanical properties.

In addition, the Ni-Cr alloys are

promising materials for structural components of nuclear and thermonuclear

reactors with water coolant. [2] In [3] studied the effect of the structural

state of Cr-Ni steels and alloys on the stability of the structure under

radiation exposure.

Solution to the problem of obtaining

a combination of practically important properties in Ni-Cr alloys are the

creation of efficient technologies and patterns of combination treatment

(thermal or mechanical-thermal) that enhance the performance properties of

these materials through targeted changes in their structure and phase

composition. As is known, the change in temperature and heating time for

hardening can get qualitatively different structural-phase states in alloys,

which in turn determine the properties and evolution of the structure of the

hardening during subsequent aging. Therefore, it seems urgent to study the

structure of the alloy after quenching in a wide temperature and time interval,

determining the optimal quenching conditions.

The purpose of this study is to

investigate the influence of quenching temperature, exposure time for quenching

and cooling rate on the phase-structural state of the alloy 47HNM.

Materials and methods of research

The material of investigation, the

alloy 47HNM industrial

manufacturing and standard

chemical composition (47%-Cr, 5%-Mo,

stop. - Ni).

During the heat treatment of the alloy 47HNM heating

for quenching of 12000-13000S

was carried out in a salt bath of molten BaCl2. Bath

temperature is automatically maintained

constant within 50C. State of the

samples were fixed by quenching

in cold water.

Structural-phase state of the samples

was investigated by optical (NEOPHOT-21,

MIM-7) and electron (EM 125K) microscopes and

X-ray diffraction method using a DRON-3.

Thin sections for metallographic

studies polished and etched electrolytically in 10% strength acetic chlorine

electrolyte. The microstructure controlled grain size, the

volume fraction of the phase, the presence of twins and other defects.

The samples for electron microscopy in

the form of discs were prepared by

jet electropolishing and by thinning of the foils.

When taking samples of diffraction on a DRON-3 was used to Co-a - radiation at X-ray tube modes U =

40 kV and I =

40mA. The calculation of the

diffraction patterns was carried out by a known method [4].

Results and Discussion

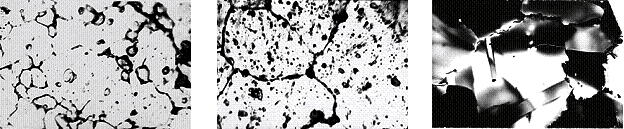

In Fig. 1, and shows the microstructure of the alloy after quenching 47HNM from

1250 ° C, performed in an inert gas.

Microstructure of a polyhedral grains γ-solid

solution with the particles of the

secondary phase. Electron

microscopic study of the alloy

after the specified heat treatment

(Fig. 1c) also show that the

alloy is in the two-phase state.

Matrix alloy is

γ-solid solution with fcc-based

Ni, a second-phase

particles - α-solid solution with bcc-based Cr. Α-phase

particles are primarily based on the grain boundaries (see Fig. 1, d), and the volume fraction of the excess phase is 5-10%. At

the micro-electron diffraction corresponding quenched samples (see Fig. 1c), visible bands that

are continuous in the reciprocal lattice, which shows, as you know, or to partially hardened, or on low speed cooling during hardening, which results in partial decomposition of the supersaturated

solid solution.

![]()

![]()

![]()

a) b) c)

![]()

![]()

![]()

d) e) f)

Fig. 1 47HNM

microstructure of quenched by 12500S 1 minute:

a - optical micrograph

(x1200); b (x850), c (x13000), e (x14000), f - electron micrographs

(x7000); b - micro-electron

diffraction pattern of Fig .1, b

An interesting feature of the structure of quenched samples

is the large number of twins, cross grain (Fig. 1, b,

c, d). Twin boundaries are mostly straight and very stable. Figure 1, e shows the intersection of

twins with extinction contours.

At low cooling rates, for

example, in the air, after the formation of high-temperature heating of twins, as a rule, is not observed.

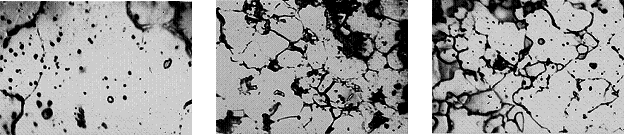

With increasing exposure time up to 10 minutes

at a temperature of quenching is further dissolution of

the hardening α-phase, with

the result that the degree of supersaturation

of the alloying components of the

matrix increases. With increasing

time of exposure to the hardening 12500S is also a change in the

structure of the alloy 47HNM,

namely, there is a growth of grains (Fig.

2a, b), the increase in assorted alloy

and the changing nature of the grain

boundaries (Fig. 2c). Typical microstructures at different temperatures and exposure time

for hardening are also  shown in Fig. 3.

shown in Fig. 3.

a) b) c)

Fig. 2 47HNM microstructure

of quenched temperature 1250ºÑ: a - 1 min. (with reproductions increased 2 times) (x1000), b - 30 min (x2000). c - 5 min (x850).

a) b) c)

Fig. 3 Changing the structure of the alloy according to the

temperature and exposure time for

hardening a - 1200 º C for 30 min. (x1000),

b - 1300 º C, 1 min. (x1000) c - 1300 º

C for 30 min (x1000).

The loss of stability of the grain boundaries,

which is expressed in a strong curvature

(Fig. 2, c, Figure

4, a, b), is a characteristic feature of the alloy 47HNM at

speeds more than 1-2 minutes

in the interval 1250-1300 ° C. In this

case there dissolving α-phase

particles and their subsequent spreading along the grain boundaries,

forming sometimes they continuous

layer (Fig. 4, c) with a high chromium content. This is confirmed by microdiffraction analysis. Allocation at

the grain boundaries (particularly strong secondary phase) can dramatically change the technological

properties of the alloy.

The loss of stability of the grain boundaries,

which is expressed in a strong curvature

(Fig. 2, c, Figure

4, a, b), is a characteristic feature of the alloy 47HNM at

speeds more than 1-2 minutes

in the interval 1250-1300 ° C. In this

case there dissolving α-phase

particles and their subsequent spreading along the grain boundaries,

forming sometimes they continuous

layer (Fig. 4, c) with a high chromium content. This is confirmed by microdiffraction analysis. Allocation at

the grain boundaries (particularly strong secondary phase) can dramatically change the technological

properties of the alloy.

a) b) c)

Fig. 4 Changes in the structure of grain boundaries in the alloy quenched

from 1250ºC 47HNM for varying the exposure time: a - 2 min. (x1000), b - 5

min. (x1000) at - 10 min (x2000).

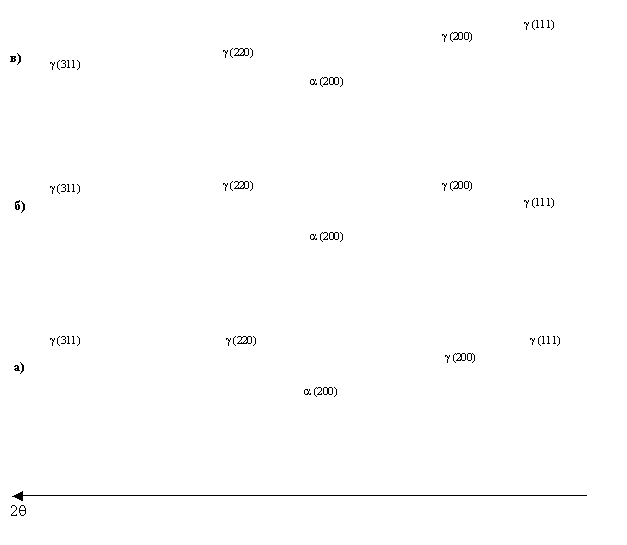

The results of X-ray diffraction patterns of the alloy 47HNM

quenched from 1250 ° C for different

exposure time are shown in Fig. 5.

Fig. 5 X-ray diffraction patterns of the alloy 47HNM

after quenching from 1250 ° C for different

exposure time: a - 5 sec., B - 30 sec., c - 10 min.

We see that all the intense lines

in the diffraction belong g-phase - solid solution of Cr and Mo in the nickel matrix c

fcc lattice. Along with them there are weak X-ray diffraction lines

of a-phase bcc. After quenching temperature 1250 ° C remain

undissolved particles a-phase. With increasing exposure time there is an increase

in the hardening of the lattice

parameter g-matrix from 3.560 to 3,568 Å and a

decrease in the volume fraction of a-phase, which after hardening

delayed 10 minutes or more practically not detected (Fig. 5, b).

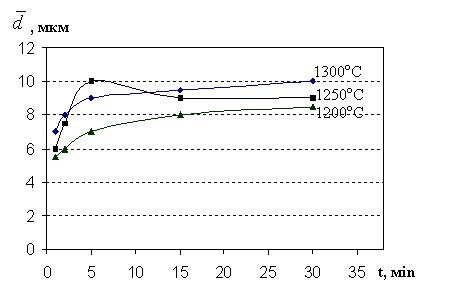

As you know, the quality of hardened material is determined not only by its technological properties, but also the size of the recrystallized grains. For alloy 47HNM interesting feature is the low tendency to grain growth in the temperature range 1000-1300ºC. In a very short time by exposing the alloy hardening process is completely primary recrystallization and formed fine-grained structure with an average grain size of 6-10 microns. Processes of primary and collecting rekristalizatsii known flows in the heating process of the deformed metal. Because of the presence of excess α-phase structure clearly reveals two groups of grains of various sizes. This is particularly undesirable in assorted operations deep drawing, stamping and etching and polishing preparations.

The main cause of assorted, apparently, is the uneven distribution of excess α-particle phase. In areas with a high content of coarse α-phase, forming small grains, whereas in regions of the material with no phase particles, grain grows to much larger sizes.

The results of electron microscopic studies of border regions of the alloy structure 47HNM allow us to conclude that, for small periods of time delay for hardening grain boundaries remain straight, and mostly free of grain boundary precipitates. However, with increasing duration

of exposure

to the hardening

temperature is

a loss of

stability of

the grain boundaries, increasing their length, and they become strongly curved shape.

The dependence of the average grain size of the alloy 47HNM the exposure time of the hardening temperature 1200-1300ºC is shown in Fig. 6.

As can be seen from the data, the grain growth in the alloy 47HNM very depressed because of excess α-phase, which inhibits the migration of boundaries during recrystallization.

Fig. 6 Change in the average grain size of the alloy 47HNM depending on time and temperature exposure during quenching

Based on these results we can conclude the following:

After quenching in the temperature range 1200-1300 º C 47HNM alloy structure is

two-phase, consisting of

grains of γ-matrix and α-particle phase. With increasing exposure time is set for

hardening solution hardening α-phase grain

growth of the matrix alloy and increase assorted changes in the nature of the grain boundaries. Grain growth in the alloy

47HNM very depressed because of the presence of excess α-phase, which inhibits the migration of boundaries during recrystallization.

Literature

1 Rahshtadt A.G. Spring steels and

alloys. - Moscow, Metallurgy,

1971 - 496p.

2 Solonin M.I.,

Kondratyev V.P. Votinov

S.N. Alloy HNM-1

as a promising material for structural

components of nuclear and thermonuclear reactors with water coolant / / VANT Series Materials and new materials. - 1995. - Issue 1

(52). -P.13-20.

3 Kolotushkin V.I.

Impact on the stability of the structural state of Cr-Ni steels and alloys under neutron irradiation

// FMM. - 2004. -T.97,

¹ 2. - P.63-73.

4. Gorelik, SS, Skakov

JA, Rastorguev LN

X-ray and electron-optical

analysis. - Moscow: MISIS, 2002. - 360 p.