EXPERIMENTAL STUDY OF VERTICAL

MOVEMENTS OF IN-PIPE INSPECTION ROBOT

S. Jatsun, doctor of

technical sciences, professor, the head of the department of theoretical

mechanics and mechatronics, South-West state university, (å-mail: teormeh@inbox.ru)

S. Savin, post-graduate

student of the department of theoretical mechanics and mechatronics, South-West

state university, (å-mail: sergey89mtkgtu@mail.ru)

S. Rublev, post-graduate student of the department of theoretical mechanics and

mechatronics, South-West state university, (å-mail: teormeh@inbox.ru)

In the present article the experimental study of vertical movements of

in-pipe monitoring robot is discussed. The results of the experiments are

shown.

Key words: in-pipe monitoring robot, testing stand, experiments, results.

Introduction

Nowadays there is an urgent problem of designing

devices, for automatization of control and diagnostic of pipes inner surface,

as well as there is a problem of designing vehicles for navigation inside

pipelines. In papers [1-3] authors pointed out the importance of creating and

using in-pipe robots as they can decrease the cost of maintaining pipelines of

different sorts. In papers [4] and [5] it is pointed out that the designing of

new in-pipe robots is important because most of the pipelines are buried

underground or placed in such way that it is difficult to gain an access to the

pipes. That makes it impossible for humans to work directly with the pipe-line

without deconstructing parts of buildings or facilities, or excavating the

pipe. In articles [6] and [7] it is mentioned that the usage of in-pipe robots

for diagnostic the state of gas pipelines, situated near houses and apartment

blocks, is important as it can gives us detailed information about the state of

the pipes and this information is critical for the companies that maintain such

pipelines. Also the usage of in-pipe robots for that purpose can help us locate

gas leakages, which is important for people security.

The design of the robot

In this article we want to discuss an in-pipe robot

consisted of two modules. The first module called inserted module. The inserted

module is moving along the pipe and transport the diagnostic equipment. The module

essentially is a link mechanism. The second module is called drive module. The

drive module stays outside the pipeline and connected with the inserted module

by flexible robes and their housings. The force generated in the drive module

transmitted to the inserted module by the means of the flexible ropes. The

inserted module consists of two sections, each can be fixated in the pipe.

When designing in-pipe robots, the question of the

impact of the weight of the equipment on the robot’s behavior is rising. For

gaining information on the subject a special testing stand was constructed.

Experimental study

The goal of the experiments, that were conducted with

use of the constructed testing stand, was to determine the value of deformation

of the flexible ropes on the different stages of the step when using weight of

the payload. Essentially, the robot was moving his first section with a payload

on it and the deformation of the flexible ropes was measured. The robot was

moving vertically in a wide enough pipe, so the moving part won’t touch the

inner surface of the pipe, during it’s movements. The value of deformation was

determined as the difference between the value h, which is how high the

first section had moved, and the value L, which represents the length,

that the ends of ropes, attached to actuators, had covered, forced by

actuators.

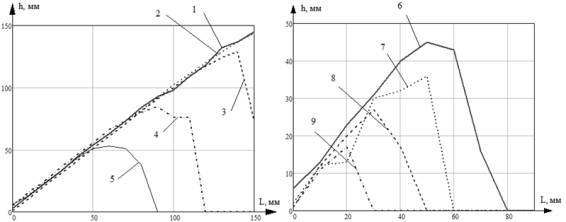

Figure 1 Relation between

the movements of the first section h and the length of ropes L. 1

– payload is 0.15 kg, 2 – 0.25 kg, 3 – 0.45 kg, 4 – 0.55 kg, 5 – 0.65 kg, 6 –

0.75 kg, 7 – 0.85 kg, 8 – 1 kg, 9 – 1.2 kg

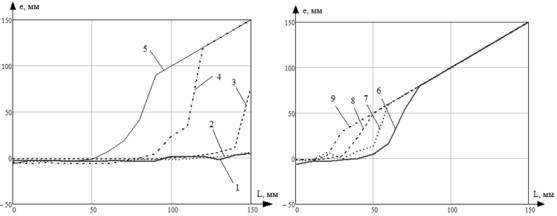

Figure 2 Relation between

e (the difference between h and L) and L

1 – payload is 0.15

kg, 2 – 0.25 kg, 3 – 0.45 kg, 4 – 0.55 kg, 5 – 0.65 kg, 6 – 0.75 kg, 7 – 0.85 kg,

8 – 1 kg, 9 – 1.2 kg

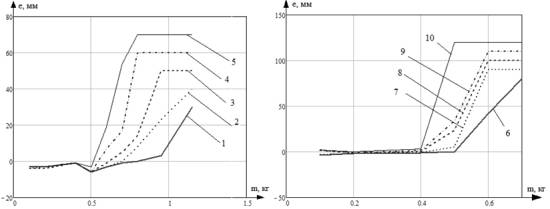

Figure 3 Relation between

e (the difference between h and L) and the value of the payload

m;

1 – L is

equal 30 mm, 2 – 40 mm, 3 – 50 mm, 4 – 60 mm, 5 – 70 mm, 6 – 80 mm, 7 – – 90 mm,

8 – 100 mm, 9 – 110 mm, 10 – 120 mm

Let us assume that regular working mode for the robot

is when the robot can keep its stability while exposed to external perturbation

actions. Let us assume that this condition is met if the value of flexible

ropes’ deformation e is less than the value L. The mode when the

robot loses stability and his form we assume to be an abnormal mode. In that

mode the value of flexible ropes’ deformation e would be larger than the

value L.

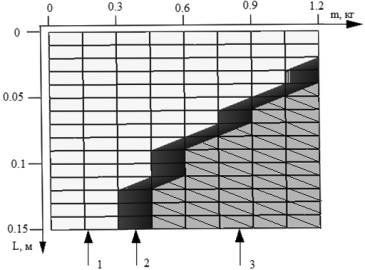

Figure 4 Parameter space of the device; 1 – the space in which the robot

is functioning in the regular mode; 2 – the space with possible bifurcations from

which the robot can move to the first space or the third space; 3 – the space in

which the robot is functioning in the abnormal mode

Making analysis of the acquired data and the result,

shown on the figure 4, we can come to the conclusion that when the weight of

the payload is increasing the maximum of the length of the step that robot can

make, while moving vertically, is decreasing. From that we can conclude that in

order to move equipment with considerable weight the robot needs to reduce the

length of it’s steps. That will increase the preciseness of robot’s movements

and guarantee the absence of emergency situations.

Conclusions

In the present paper the results of conducted experiments

are shown. The results gives us opportunity to see the characteristics of the

movements of the in-pipe robot, while moving vertically. Three parameter spaces

were discovered. The first one represents the regular mode of the robot

functioning. In that mode robot can keep its stability while exposed to

external perturbation actions. The second parameter space represents

bifurcations area, in which it is possible for the robot to move into the first

space or the third space. The last parameter space represents the abnormal mode

of the robot functioning. This data can be used in designing in-pipe robots,

that need to move vertically. Also this data can be used in programming and

making software for such robots, in order to take into account the deformation of

the flexible ropes, which depends on the number of factors, including the

weight of the payload.

REFERENCES

1

Se-gon Roh Differential-drive in-pipe robot for moving inside urban gas

pipelines / Se-gon Roh, Hyouk Ryeol Choi // IEEE Transactions on robotics, VOL.

21, NO. 1, February 2005 – 17 c.

2

Hyouk Ryeol Choi In-pipe robot with active steering capability for

moving inside of pipelines / Hyouk Ryeol Choi, Se-gon Roh // Bioinspiration and

Robotics Walking and Climbing Robots, Maki K. Habib (Ed.), ISBN: 978-3-902613-15-8,

2007 – ñ. 376-402

3

Se-gon Roh Navigation inside pipelines with differential-drive inpipe robot

// Robotics and Automation, 2002. Proceedings. ICRA '02. IEEE International

Conference on, Volume 3 / Washington, 2002 – 2575-2580 ñ

4

Shuichi Wakimoto A micro snake-like robot for small pipe inspection [Òåêñò] / Shuichi Wakimoto, Jun Nakajima, Masanori Tanaka,

Takefumi Kanda, Koichi Suzumori // Mechanical Engineering fields, Okayama

University – Okayama, 2003 – c. 303-308

5

Ono Manabu Development of an in-pipe inspection robot movable for a long

distance / Ono Manabu, Hamano Toshiaki, Takahashi Masato, Kato Shigeo // Nippon

Kikai Gakkai Robotikusu, Mekatoronikusu Koenkai Koen Ronbunshu, 2001, ¹1; 91-92

ñ.

6

Dertien E. Basic maneuvers for an inspection robot for small diameter

gas distribution mains / Dertien E., Stramigioli S. // Robotics and Automation

(ICRA), 2011 IEEE International Conference on, Shanghai International

Conference Center – Shanghai, 2011 – ñ. 3447-3448

7

Dertien E. Development of an inspection robot for small diameter gas

distribution mains / Dertien E., Stramigioli S., Pulles K. // Robotics and Automation (ICRA), 2011 IEEE

International Conference on, Shanghai International Conference Center – Shanghai,

2011 – ñ. 5044-5049