About speed of

electromagnetic atomizers in systems of injection of fuel

V.I. Sarbaev, J.V. Garmash,

T.S. Valova

Introduction. Application of systems of injection of fuel provides increase of fuel

profitability and decrease of toxicity of fulfilled gases, optimizes process mixing

of a fuel - air mix [1, 2]. With the purpose of increase dynamics the

automobile, reliability of start-up, increases of capacity of the engine apply

systems of the coordinated injection of fuel which in comparison with the

central injection have more error of batching of fuel because of small cyclic

submissions. Identity of structures of a gas mixture on cylinders in the

greater degree depends on non-uniformity of batching of fuel atomizers, than

from a design of inlet system. The quantity of air acting in the cylinder for a

cycle, pays off the block of management according to the gauge of the charge of

air and frequency of rotation of a cranked shaft of the engine. Atomizers

should have nonlinearity of the characteristic of batching of fuel within the

limits of 2 - 5 % during all service life (about 600 million cycles of operation).

They work in a pulse mode at frequencies from 10 up to 200 Гц and even above in conditions of vibration of the engine and the

raised(increased) temperatures [1, 2].

Statement of a problem. In the case of an

atomizer the locking element of the valve pressed to a saddle by a spring is

located. When on a winding of an electromagnet from the electronic block of

management the electric pulse of the rectangular form of the certain duration

moves, locking element moves, overcoming resistance of a spring, and opens an

aperture of a spray and fuel acts in the engine. After the discontinuance of an

electric signal locking element under action of a spring comes back in a

saddle. The quantity of injected fuel for a cycle (at a constancy of pressure

in bringing pipeline) depends on duration of managing pulse.

In a real atomizer time of an open condition of the

valve does not coincide with its duration. After submission of managing

electric pulse on an atomizer in a winding of an electromagnet there is the

current of a self-induction interfering increase of a magnetic stream in

system. At a stopping delivery of managing pulse as a result of a

self-induction the kept magnetic stream will interfere fast stop locking element. To

increase speed of an electromagnetic atomizer it is possible due to reduction

of inductance. However thus resistance of a winding decreases and the current

consumed by it is increased, questions of reduction of operation of time of an

electromagnetic atomizer now completely are not developed also their research

is actual and yet the not decided problem [1-5].

The basic part. With the purpose of an estimation of an opportunity of regulation of

time of operation of an atomizer, we shall consider some common questions of

calculation of transients on an example of inclusion of a consecutive contour

(rLC - circuits) to a source constant voltage forces (E).

It is accepted to count, that transitive the process

occuring in a circuit, it is possible to consider consisting of two processes

imposed against each other - established, and free, having a place only during

transient. During operation tср an electromagnet accept duration of action from the moment

of submission of a pulse of operation up to the moment of the ending of moving

of an anchor from one extreme position in another. This time can be divided

into two components: move time tтр - a time interval from the moment of submission of a

pulse on a winding of an electromagnet up to the moment of the beginning of

movement of an anchor (it is the greatest part tср) and time of movement

tдв - an interval from the

moment of the beginning of movement of an anchor up to its full stop.

At inclusion of a winding of an electromagnet

transient will be determined by the equation:

![]() , (1)

, (1)

Where

U - a voltage of the power supply of a circuit, V; i - value of a current in a

winding, A; R - resistance of a

circuit of a winding, Ohm; Ψ - instant value full stream coupling windings, Vb; t - time, S.

Deciding

the equation (1), we shall receive the known equation for a current at constant

initial inductance ![]()

, (2)

, (2)

Where

![]() , s,

, s, ![]() - Initial inductance, H - found at a reference value of a backlash in a magnetic circuit of an

atomizer.

- Initial inductance, H - found at a reference value of a backlash in a magnetic circuit of an

atomizer.

For

final inductance at final value of a backlash in a magnetic circuit of an

atomizer by analogy it is received:

, (3)

, (3)

Where

![]() , s.

, s.

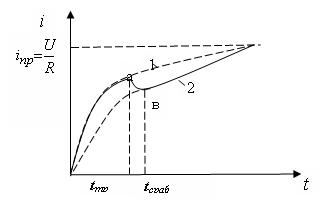

The settlement oscillogram of a

current for a nonsaturated electromagnet is shown in figure 1 by 1 continuous

line, the experimental oscillogram of a current of an atomizer has the same

kind.

Figure

1 - Oscillograms of a current at

no

saturated magnetic circuit

Prior to the beginning of movement

of an anchor the current changes according to the (3) (on the oscillogram this

change corresponds to a curve 1) from a constant of time τн. On the expiration of move time movement of an anchor and a current

begins changes on a curve ав,

appropriate to movement of an anchor of an electromagnet.

In

the literature [6] it is marked, that at work on the impoverished mixes and on

high revolutions engine time of operation should be no more than 0,3ms. The

point in, laying on a curve 2, corresponds to full time of operation. Expression

for time ![]() allows to receive the received

equations:

allows to receive the received

equations:

. (4)

. (4)

The analysis of this equation shows, that ![]() depends both on a voltage of a feed,

and from resistance of a winding. And stronger dependence is observed from

active resistance in a circuit of a winding.

depends both on a voltage of a feed,

and from resistance of a winding. And stronger dependence is observed from

active resistance in a circuit of a winding.

However at consecutive connection to an atomizer of additional

resistance alongside with reduction of time of operation it is reduced as well

its reliability that is caused by reduction of the established current. It is

obvious, that simultaneously with increase of resistance of a circuit, it is necessary

to raise and a voltage on it, that it is possible to realize, with the help of

raising converter of a voltage. The circuit of connection of atomizers to an

onboard network can be executed, for example, on figure 2.

However at consecutive connection to an atomizer of additional

resistance alongside with reduction of time of operation it is reduced as well

its reliability that is caused by reduction of the established current. It is

obvious, that simultaneously with increase of resistance of a circuit, it is necessary

to raise and a voltage on it, that it is possible to realize, with the help of

raising converter of a voltage. The circuit of connection of atomizers to an

onboard network can be executed, for example, on figure 2.

Thus it is necessary to mean, that the voltage on an

atomizer should maximal be direct at the moment of receipt of a pulse of management

is will allow to provide the greatest speed of increase of a current, and,

accordingly, to reduce time of operation of an atomizer. After end of process

of operation there is no need in the increased voltage - it should be such to

provide deduction of an electromagnet up to the moment of the ending of

managing pulse. Hence, the converter of a voltage should be controlled.

Moreover, the voltage on an atomizer should be adjusted depending on power

setting internal combustion [7].

Experimental part. With the purpose of

check of the assumption of dependence of time of operation on a voltage and

resistance of a circuit of an atomizer we carried out experimental researches. Time

of operation was determined on the location of characteristic change of a

current on the oscillogram (figure 1).

In figure 3 experimentally received dependences of time of operation of

atomizers on a voltage are given at the various resistance in addition included

in a circuit of an atomizer.

In figure 3 experimentally received dependences of time of operation of

atomizers on a voltage are given at the various resistance in addition included

in a circuit of an atomizer.

From experimental data follows, that at additional resistance

in a circuit of an atomizer 19,5 Ohm time of operation decreases, in comparison

with initial, approximately in 5 times and makes about 0,5 ms.

Conclusions. We offer rather simple

way of reduction of time of operation of the electromagnetic atomizer, allowing

without essential expenses smoothly to adjust speed of its operation. There is

an opportunity at change of power setting by the given image to adjust time of

operation, not changing a mode of operation of electronic blocks of management

of systems of injection and ignition.

The literature

1.

Автомобильный

справочник «Бош» [Текст]: Пер. с нем. - М.: За рулем. - 1999. - 895 с.

2.

Будыко, Ю. И. Аппаратура впрыска

легкого топлива автомобильных двигателей. [Текст]: учебное пособие/ Ю.И. Будыко. - Л.:

Машиностроение. - 1975. - 192 с.

3.

Любчик, М. Н. Расчет и проектирование

электромагнитов постоянного и переменного тока [Текст]: учебное

пособие/ М.Н. Любчик. - М.: Госэнергоиздат.

- 1959. - 98 с.

4.

Любчик, М. Н. Силовые

электромагниты аппаратов и устройств автоматики постоянного тока [Текст]: учебное пособие/ М.Н.

Любчик. - М.:

Энергия. - 1968. - 123 с.

5.

Пеккер, И. И. Физическое моделирование

электромагнитных механизмов [Текст]: учебное пособие/ И.И. Пеккер. -

М.: Энергия. -

1969. - 106 с.

6.

Bosh. Системы управления бензиновыми

двигателями. Перевод с немецкого [Текст]/- Первое русское издание. – М.: За

рулем. - 2005. - 432 с.

7.

Гармаш, Ю. В. О регулировании времени

срабатывания электромагнитной форсунки [Текст]/ Ю.В. Гармаш, Т.С. Валова//Международная научно-практическая

конференция «Наука и образование XXI века». – Рязань. –

2007. - С. 238-243.