Stochastic features of

formation of a temperature field of preparation when grinding

Dyakonov A. A.,

Ermilov S.A.

South-Ural State

University, Russia, Chelyabinsk

Occasional

approach to thermal-physic task decision of grinding theory and numeral

analysis based on imitation model realization by means of computer for the

first time allow discovering the number of physical particular qualities of

temperature field blank formation in this process.

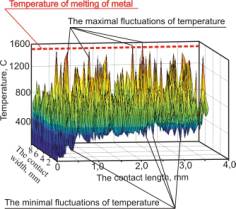

The

fig. 1 illustrates, there is the contact length at the axis of absciss and

there is the grinding width at the axis of ordinates. It allows to monitor the

nature of temperature field formation in the contact zone both in the cutting

moment by grains (maximal temperature tops) and in the «rest» time until the

next grain enters when the material is getting cold. At the graphs you can see

the critical fluctuation points of temperature field – maximal and minimal

temperature. Furthermore, the temperature field has the not stational and

irregular character both at the contact length and the contact width, in other

words the temperature fluctuations move to the area of higher temperature at

time.

Fig. 1. The temperature field blank kind by grinding

For the all materials the maximal temperatures could reach and even

exceed melting-point and independently on processing kind. It is the

demonstration of one assumption influence using in thermal-physics model,

namely metal – isotope and while

calculating its phase transformations during heat spread process (latent warmth

melting) are not taken into account. It allows avoiding nonlinear thermal

conductivity differential equation. It is very important to solve this problem

for investigations those concerned with determination of structural changes in

the surface layers. This problem is not discussed in the present report.

Moreover, A.A. Koshin [1] represents that material melting temperature is

available only on the surface, and in the significant volumes of surface layers

determining the quality of processing this effect is not monitored.

Thus, the maximal temperature that appears in the thin surface layers,

could reach physically the melting-point and since this time the getting cold

happens whish is describing in the designed thermal-physics model.

The particular cases are recognized after analyzing the great number of

temperature field diagrams. So, for the all examined material marks

independently on the grinding kind, the sudden increases and drops interchange

in the temperature of getting cold is monitored in the high temperature zone.

It is concerned with nonlinear changes of dependence “Solidity-Temperature” for

that diapason in which the meanings of material solid characteristics (σi) and intensity heat sources

(q) are not taking into account.

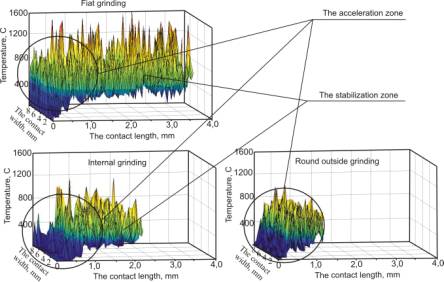

Comparing

the given temperature fields for different kinds of grindings it could be

established that while the contact length increases the temperature gradient

increases too. So, during the round outside grinding of carbon steels the

average temperature gradient is 380 °C, during the flat grinding – 650 °C and

during the internal grinding – 310 °C.

On the

other hand, the temperature increase is not proportionate to contact length

increase as correlation of the contact length at flat and outside round

grinding at average technological conditions is 3,8 : 1, and correlation of

temperature is 1,7 : 1. This event could be explained by availability of acceleration

and stabilization zone (fig. 2) at temperature field. The drastic temperature

increase that practically equals the maximal temperature happens on the contact

length that is 1 mm not dependently on grinding kind, and the future

development of temperature field happens at stabilization dependence relatively

to abscissa axis. However the part of acceleration zone of the contact length

for every kind is not similar, for example, for the round outside grinding it

is 100%, for the internal grinding – 62%, for the flat grinding – 25%.

Fig. 2. Characteristic sites of temperature field blank formation

Consequently

the temperature field blank by grinding possesses of two criteria zones: the

zone of drastic temperature increase (the acceleration zone) and the

stabilization zone.

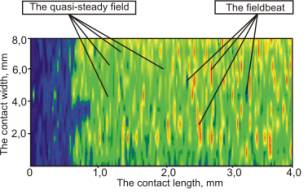

Modification

of the given diagrams into the line level diagrams (fig.3) allows to monitor

distribution and heterogeneity of temperature field blank in the contact zone.

Fig. 3. The line

level heterogeneity diagram of temperature field blank

in the contact zone by grinding

Fig. 2

illustrates quasi-stationary temperature field is created in the results of the

frequent influence of abrasive grains on the stabilization zone that is 800

ºÑ, due to occasional grinding

process temperature pulsation happens in the interval of 200–1400 ºÑ.

The

main particular quality of temperature field, which was idealized vastly by

investigators [2], is occasional character of its formation. Starting from this,

to evaluate temperature field in the contact zone the application of

mathematical statistics is required as the average of temperature in this case,

obviously disfigures the real situation.

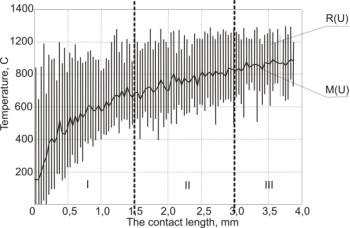

Two

central moments of mathematical statistics are implemented for evaluation:

M (U) –

mathematical temperature waiting in the considered interval at the contact

length;

R(U) –

swing of temperature relatively to mathematical waiting in the considered interval at the contact

length.

Two-parameter

evaluation system was realized by computer statistics prognostication STATISTICA

6.0. To determine mathematical waiting

M (U) and swing R (U) in every interval at the contact length the meanings of

temperature at the contact width included in this interval are considered.

The

example of trusting temperature field evaluation at flat grinding of AISI304 is illustrated on the fig. 4. The results confirm the

necessity of two-parameter evaluation system as the swing in the dependence on

the considered contact length could obtain 220–980ºÑ. The analyzing of the graphs allows concluding that

temperature field blank possesses additional particular qualities besides indicated

earlier.

Fig. 4. The

temperature swing interval statistics

The

temperature swing obtains the different meanings on the individual contact

length in which connection its meaning decreases while the contact length

increases.

The temperature swing interval statistics

|

The grinding kind |

Number of the site |

||

|

I |

II |

III |

|

|

R (U), 0Ñ |

|||

|

Round outside |

530 |

500 |

421 |

|

Internal |

550 |

390 |

– |

|

Flat |

560 |

421 |

320 |

Conclusion

Occasional

approach to thermal-physic task decision of grinding theory and numeral

analysis based on imitation model realization by means of computer for the

first time allow discovering the number of physical particular qualities of

temperature field blank formation in this process.

It was

established that temperature field has quasi-stationary occasional character.

It was

discovered that availability of two criteria zones – the acceleration zone was

defined by drastic temperature increase

and the stabilization zone was conformed by constant level of temperature field

formation – is typical for temperature field in the contact zone by grinding.

The

statistic characteristics – two central moments of mathematical statistics: the

mathematical waiting M(U) and the swing R(U) are offered for numeral evaluation

of temperature field blank in the grinding zone.

References

1.

Koshin A.A. Research of physical

communications at grinding // The Processing

of metals. Novosibirsk, 1997. ¹1. P. 22–25.

2.

Korchak S.N. Productivity of process of

grinding of steel details. M.: Mechanical

engineering, 1974. 280 p.