Zhantugulov T.

Kostanai

State University named after A. Baitursynov the Republic of Kazakhstan

Extruding

of multicomponent forage

One of the reserves of efficiency growth in forage

preparation – usage of extruding compound feed in animals ration. Extruding provides effective mechanical impact

on forage components, destroys material structure, increases nutritional value

and edibility of forage. Herewith it is possible to process old, dry forage, processing is connected with high temperature up to

200ºÑ and pressure up to 25 MPaS,

that promotes elimination of the microbiological content, transmitted

through forage, at the expense of

extrusive processing the range of forages increases. However extruding is a power-intensive process wherein forage may leak

between frame and the end of the screw curl

in consequence of which there is

forage gumming- up between surface and

frame wall therefore efficiency increase of extruder operation is an actual

task.

Advanced technologies of compound feed production

processed in the agricultural products processing field, confirmed

necessity of compound feed extruding,

i.e. multicomponent fodder materials, their wastes (including monoforages,

monodiets) [1,2,3].

Researches of the processes which are taking place in

extruder,it is connected with change of rheological properties of processed

materials, according to the construction of extruders for their processing

because forage composition changes,

dragging coefficient also changes. S. S. Dzhingilbaiev, studying

extruding processes of oilseeds, described them in the connection with the

laws of keeping and transformations of energy ( the first law of

thermodynamics). Made or received

heat Qt minus lost heat Ql is equivalent to quantity of the

transmitted energy – operations which, in their turn, are defined as common difference from the useful operation

on compression of Ad and from the dragging forces hindering carrying out useful operation Ac [4]:

Qt

– Ql = Àc – Àd (1)

Operation of dragging forces will respectively change

in case of change of processed material composition, for example, in the course

of multicomponent materials processing.

Some researchers confirm, that extruder combines a number of operations in

one machine, which mixes, compresses, heats, cooks, sterilize, forms. It is

necessary to understand that it (extruder) substitutes the whole complex of

machines, increasing food value, digestibility of processed material.

Other researchers developed

processing modes of barley, corn, wheat for increase of nutrients digestibility

and grain disinfecting in extruders. It is recommended to grind grain in hammer

grinder before extruding (a sieve with 3 mm diameter mesh) and to humidify

to17-18% .

However it is more effective to steam out crushed

grain or mixes of grain components before extruding. For this purpose the

extruder should be equipped with the mixer – steamer, from which a product is

directly sent to the extruder screw.

We conducted the pilot researches on processing of multicomponent

forages in the extruder (monoforages, monodiets).

At this way of grain preparation the productivity of the extruder increases by

25-30% [1]. But usage of extruding forages, feed mixes shall be carried out

according to a diet of animals feeding, i.e. it shall comply with well-

balanced, easily digested forage for animal organism.

At researches conducting the following conditions were taken into

account: the rotational frequency of the extruder screw (X1); feed mix

humidity (X2 – from 8 to 32%); the

filament extrusion device length (X3 – from 32 to 96 mm); skew angle of the

screw surface (X4 – from 5 to 25 degrees); diameter of the extruder screw is 70

mm. Quality of the processed material was checked on the content in the

extruder of starch and dextrins and compared with the basic material.

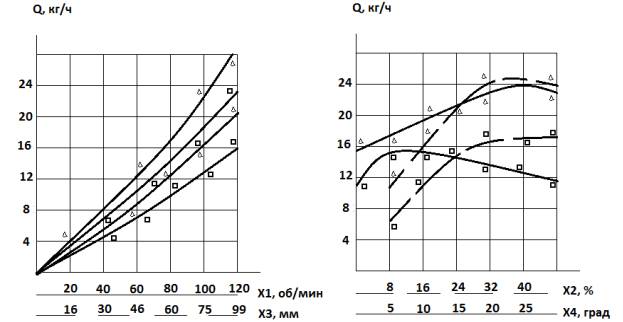

Figure 1. Dependence of productivity on

the rotational frequency (X1) and the length of the filament extrusion

device (X3) - a, dependence of productivity on humidity (X2) and skew angle

(X4) –b:

Δ-monoforage (consisting of grain wastes, mill offal homogenous in

composition);

- monodiet (consisting of

grinded grain, mill offal, straw).

As a result of the researches data processing were

received productivity dependences on the reference conditions ( figure 1, and,

b).

The analysis of dependences shows that under equal

conditions of processing indexes of monoforages are higher, than ones of

monodiets. In case of increase in rotational frequency of the screw (X1) and

increase of the filament extrusion device length (X3) it occurs the increase in

productivity of researched intervals. In

case of humidity change of feed mix from 8 to 50% productivity reaches the

crest value at 36-40%, in case of change of screw surface skew angle (X4)

productivity reaches the crest value in case of monodiet processing at 5 °

angle, in case of monoforage processing at 25 °angle. The result of quality

determination confirmed the increase of dextrins quantity to 32%.

Literature:

1 . L.Boiko. Progressive technologies for feed mixes production. Feed mixes ¹4. Technique and technology. 2005.

2 . Experience of extrusive technologies usage. Feed mixes. ¹7 Technique

and technology.2005

3 . The new extruder – highly nourishing forages from wastes. Technique

and technology. Feed mixes ¹5

4 . S. S. Dzhingilbaiev. Energy and heat transmission of screw

extruders. Herald of the national

engineering academy of the Republic of Kazakhstan, 2006.