Korniyenko B.Y.

National aviation university, Ukraine

Research the two-phase models of the dehydration and granulation

in a fluidized bed

Granulation process are varied on methods

for their implementation, and on the hardware design. One of the promising methods

is receiving a granular product in a fluidized bed apparatus. The essence of

this method is applying the liquid phase on the surface of fluidized bed.

Solution disperses inside fluidized bed or distributed over its surface

evaporation in the previous flare spraying or without him. This makes it

possible to combine a number of stages of the process (neutralization,

evaporation, crystallization, drying and granulation) in one device that

determines the significant technical and economic effect. It can maximize the

heat of chemical reactions, which further determines the economic feasibility

of the method.

It should be noted, that the granulation

in fluidized bed (particularly when multicomponent fertilizers is received) is

a complex physico-chemical process, during which the intensity depends on many

factors. These factors primarily include patterns of fluidized bed

hydrodynamics, regulation disperse composition of the finished product, and the

intensity of the flow of heat-mass transfer processes. The complex nature of

particle motion in the flow of coolant gas in a fluidised bed granulator can be

represented in the form of two-phase flow [1].

The purpose of this article is

researching a mathematical model for determining the temperature fields during

the intense heat and mass transfer processes in the production of mineral

fertilizers in a fluidized bed granulator.

Complex multifactorial process of solid

composites with liquid systems can be divided into two stages: the first -

transport processes in the interfacial contact and making mass crystallization

with simultaneous formation of solid composite as spherical granules and the

second - the organization of the process in dispersed systems using techniques

of fluidizing.

The main requirement in creating

composites with desired properties which contain mineral and organic matter, is

the uniformity of their distribution throughout the volume. In the case of

waste water solutions of ammonium sulfate production of caprolactam to create

granular nitrogen fertilizer humic new generation of the most appropriate mass

crystallization from liquid systems that simultaneously contain both chemical

substances. The intensity of the supply of heat to the liquid phase and the

colloidal particles of organic matter determine the size of the microcrystals

at 10-7-10-6 m.

The most effective way to implement the

mechanism of formation of mineral-humic solid composites are fluidized bed

apparatus. This device will combine a number of necessary technological stages

with a coefficient of thermal energy more than 60%.

The peculiarity of these processes is the

presence of a phase transition. That supply the required amount of heat to

evaporate the solvent, the formation of a layer of microcrystals and fixing

them on the surface of the particles.

The main

requirements of the process is the formation of superfine liquid film by

adhesive forces and sorption on the surface centers granulation.

In view

of the above, the physical essence of adhesively-sorption method dehydration

and granulation liquid composite systems is fine spraying liquid composite

systems inside fluidized bed, which achieved almost complete saturation pairs

of moisture agent (coolant) and heavy traffic hot particulates through this

area. As a result, the surface of the granules formed by the action of adhesive

forces and sorption ultrathin film of liquid.

Further transferred to the particulate

relaxation zone where distributed between dry granules. In this case heated dry

granules give warmth wet granules, accompanied by partial evaporation of

moisture. As a result, all the beads in contact zone of intense heat and mass

transfer at the gas-distributing device absorbs heat energy wasted by

evaporation and creating micro bed dry matter on their surface. This prevents

them from overheating. The described cycle is repeated repeatedly.

Consequently, the grain structure is a frame of microcrystals mineral

substances which are deposited on the surface of colloidal particles of organic

impurities.

For multivariate modeling processes of

dehydration and granulation in fluidized bed is used two-phase Euler-Euler

model [1]. For each phase account for mass transfer between phases,

availability and lift forces acting on a particle - friction, pressure forces,

gravity forces Archimedes adhesion of particles on the phase boundary.

Transport equation temperatures granules

taken into account convective heat transfer, solid phase voltage, flow

fluctuation energy scattering energy collisions, the energy exchange between

the phases. It is possible to determine the intensity of the interaction of the

gas (solid) environment and solid particles (dispersed phase) at different

hydrodynamic regimes and the corresponding temperature change granules during

dehydration and granulation [2].

Mathematical model [2] takes into account

the peculiarities of the process, but the large amount of calculation time

complicates its use in driving the process of dehydration and granulation in

fluidised bed in real conditions.

Therefore we propose a simplified mathematical

model, that is almost the same as model above, but significantly improves its

adaptation in driving the process of dehydration and granulation in fluidized

bed.

The mathematical model takes into account the Complex of the

process, which is accompanied by a phase transition, is complicated by the

formation of a liquid phase on the surface of the granules with the subsequent

release of the liquid phase and the formation by mass crystallization layer

microcrystals of soluble phase.

In this approximation, the two phases - solid and dispersed

- modeled as two interpenetrating solid. Phases interact continuously in time

and space. This principle is applied in the continuous averaging to local

instantaneous momentum and energy equations.

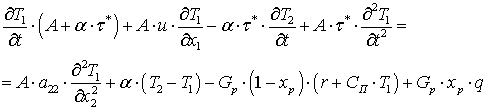

Energy equation for the temperature of the emulsion T1

and gas bubbles T2:

;

(1)

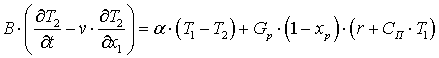

;

(1)

; (2)

; (2)

where A - share volume of a layer occupied by emulsion

phase; B - share volume layer occupied by loops bubbles; u, v - speed emulsion

and gas phase, m/s; r - heat of vaporization, J/kg; q - heat released by

crystallization solution, J/kg.

Using equations (1) - (2) we are

calculated the main characteristics of the emulsion temperature dehydration

unit and fluidized-bed granulation. The height of apparatus H (x1)

and width device L (x2) is a dimensionless quantity.

Left and right wall of the apparatus

considered as adiabatic for both phases of fixed temperature 373 K for both

phases. At the top of the layer of emulsion phase adopted a continuous wall

with leak.

A mathematical model adequately describes

the dynamics of coolant temperature and the emulsion layer height during heat

mass transfer processes in moving granular material through the irrigation

zone, intense heat and mass transfer relaxation, in which a layer of dry matter

of microcrystals minerals.

The variation of

temperature can knit connection with physical and mechanical properties of

granules, which determine the quality of the resulting product. Therefore, this

mathematical model can be used to create an effective system of control in the

formation of mineral fertilizers in the fluidized-bed granulator.

Bibliography

1.

Korniyenko B.Y. Features modeling of transport processes in disperse systems / B.Y. Korniyenko // Journal

of the National Technical University of Ukraine "Kyiv Polytechnic

Institute" series "Chemical engineering, ecology and resource

conservation". – 2011, ¹ 2(8). - P. 5-9.

2.

Korniyenko B.Y. The dynamics of the processes of dehydration and granulation

in fluidized bed / B.Y. Korniyenko // Journal of the National Technical

University of Ukraine "Kyiv Polytechnic Institute" series

"Chemical engineering, ecology and resource conservation". – 2012, ¹

1(9). - P. 15-19.