1Zharkevich O.M., 1Zhetessova G.S, 1Pleshakova

E.A., 2Utepova G

1Karaganda State Technical University

2Karaganda State Industrial University

Pseudo

alloyed coatings and their properties

Materials with pseudo

alloyed structure are a special kind of composite coatings. They consist of

materials which do not form solid solutions and compounds in liquid and solid

state, i.e. they are different melting temperature and not alloyed together. Coatings

combine the properties of each component due to the absence of any interaction

of these materials to a great range of concentrations and temperatures. During

application each of the particles are retained in the applied metal layer alone

(Figure 1), although they were metallization in a molten state.

Figure

1 - The microstructure of the pseudo alloyed coating system Cu-Cr

Such coatings are called pseudo alloyed coatings. They are characterized by a number of

important properties. This combination of high melting and evaporation

with mechanical strength, hardness, damping capacity, high wear resistance (low

friction coefficient), the ability to self-lubricating conditions in dry

friction. Pseudo alloyed coatings have high electrical and thermal

conductivity. Required properties pseudo alloyed coatings obtained by changing the ratio of the

components. The same processes of manufacture: liquid phase, solid phase

sintering, and impregnation properties substantially influence on pseudo alloyed coatings.

Coatings with pseudo alloyed structure can be prepared by methods spark

alloying, ion-plasma magnetron sputtering and thermal gas (plasma, flame,

electric metallization).

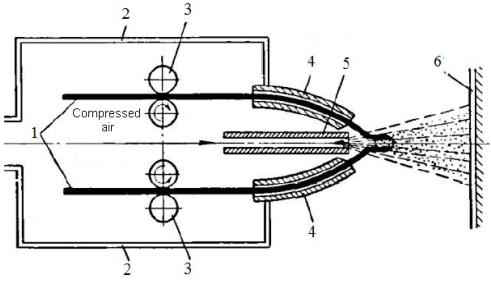

A method of arc spraying is

most prevalent during the application pseudo alloyed coatings, because offering high performance and

manufacturability. Layer thickness may vary from 50 ... 100 microns to 3 ... 6

mm or more. The coating composition is adjusted by changing

the wire diameter and feed rates (Figure 2).

1 – wire from

sprayed metal; 2 - wires; 3 - mechanism for the wire; 4 - tips for wire; 5 - air

nozzle; 6 - be plated detail

Figure

2 - Scheme of the spray head

Specific

structure pseudo alloyed coating gives it high friction properties. Characteristic

features of pseudo alloyed coating are heterogeneity and microporosity. The

heterogeneity of the structure, the presence on surface roughness layer and

pores (8 ... 12 vol. %) provide favorable conditions for preservation in the

process of friction oil film even after lubrication. The mechanical

properties of the coating pseudo alloyed connected with its structure. They

depend on the process parameters, which change the shape and the number of

occurrence oxide, particle size and shape. Thus, an increase of air

pressure in arc spraying enables to obtain finer layer structure but causes

substantial oxidation of the sprayed coating material. Spraying distance also

has a great influence on the physical and mechanical properties of the

coatings. At increase distance of 25 to 300 mm oxidation sprayed particles is

increased and the amount of oxides in the layer increases from 10 to 40%.

Moreover, sprayed particles reach the surface and therefore more cooled reduced

coating strength characteristics.

Physical and

mechanical properties pseudo alloyed coating can be improved by heat treatment,

which is subjected to pseudo alloyed coating consisting completely of

refractory metals or containing a predominant amount, as well as coating of the

color pseudo alloys. Heat treatment may be subjected to the forest complex constructions that

work with alternating loads, i.e. under stress in compression and tension. For

such details are recommended thermal pretreatment and subsequent

high-temperature tempering, i.e. sorbitizing.

Pseudo alloyed

coatings not exclude preliminary thermochemical treatment. Such as cementation,

i.e. the saturation of the carbon steel surface and subsequent spraying. Such

pre-heat treatment should be carried out for low-carbon steels, which are used

to manufacture heavy duty details, that is, experiencing alternating loads.

Pseudo alloyed

coatings produced by the method of electric arc spraying, used as anti-friction

material in friction slip have several advantages. Pseudo alloyed antifriction

coatings well and quickly burnished and show less tendency to pilling compared

to other anti-friction coatings. Using Cu-Pb as an antifriction coating material on the

internal working surfaces of steel bushings is effective. Cu-Al

coating with a mass concentration of copper 20% is recommended for sliding

bearings operating in knots of metal-cutting equipment and handling devices.

Pseudo alloyed

coating steel-Al is sprayed to improve the wear resistance of the pistons on

their way to the surface of the arc. To improve the quality of the coating

prior to application of pseudo alloyed layer is sprayed sub layer of aluminum,

which is easily deformed under the influence of shrinkage stresses encountered

in applying to it the pseudo-aluminum. This prevents the formation of cracks

and enhances adhesion of the coating to the substrate.

The above data

indicate the effective use of metalized pseudo alloyed coatings as

anti-friction, wear-resistant corrosion-resistant materials.

Anti-friction pseudo

alloyed coating is used in the manufacture of sliding bearings instead of

bronze and babbitt to improve the working capacity of products in terms of

abrasion as during the initial hardening.

References

1.

Andreev A.V. Foundations of physical

chemistry and technology of composites. - M .: Radio, 2001. - 192 p.

2.

Shahparast F., Davies Â. L. A study

of the potential of sintered iron-lead-tin alloys as bearing materials // Wear.

— 1978, — ¹ 1, — P. 145 - 153.

3.

Timokhova O.M., Scholl N.R. Study of

nanomaterials in surface hardening machine parts. // Magazine "Systems. Methods.

Technology ".

- 2012, - ¹ 4 (16), - P. 120 - 123.

4.

Dokukina

I. A., Bobrov G. V., Barvinok A. V. Investigation of wear resistance of

composite thermal coatings. // The problem of mechanical

engineering and automation. - 1996, - ¹ 1-2. - Ð. 91 - 93.

5.

Vansovskaya K.M. Metal coatings deposited by

chemical means. - M: Mechanical Engineering, 1985. - 246 p.