Smolentsev V.P. (Doctor of Technical Science), Safonov

S.V. (Candidate of Pedagogical Science), Koptev I.I.

Voronezh State Technical University

The

improvement of the flow duct of heat engine sprayers

The article deals with issues related to customizing the flow duct of

heat engine sprayers. It discovers the scope of effective implementation of

electrical processing methods, the use of which has not only enabled the

successful modification of the duct

area, but has also helped to impart the nozzle shape to the duct. This task is

not feasible with other processing methods due to limited tool access to the

nozzle at the supply end of the flow duct. The problem of component spray

management has been solved for sprayers working together on a single fire board.

Êew words: sprayer, flow duct, channels, consumption,

spraying, channel shape, electrical processing methods.

Introduction

In the manufacture of heat

engines, it is required to apply different types of sprayers supplying the fuel

to the combustion zone, while ensuring the individual conditions for media

flowing in each channel. The main criteria of evaluating the performance of

sprayers are the consumption of components and the jet spray at the outlet of

the channel. Both figures must be within the range, established for each

channel. If sprayers are combined as one fire wall, board or base, it is

necessary to obtain the individual characteristics of them depending on their

location on the fire wall, and ensure the required jet interaction in the

process fluid during its supply to the combustion zone, using technological

methods. The configuration of sprayers, based merely on component consumption,

does not allow to obtain the required operational parameters since it does not

provide the desired combination of total jet density and total consumption of

air-fuel mixture. Testing the multijet sprayers may reveal the section size of

one or several channels exceeding the limit values, specified by the drawing.

Previously, such products were considered to be faulty, which could entail

heavy material loss and the failure to meet the deadline for assembly of

newly-made product sets.

The new techniques and devices proposed by the authors as inventions,

are used for implementing the combined methods of creating channels in sprayers

while inducing an electrical field, which permits to shape the high-quality

channels of any profile (including the ones with a Laval nozzle profile),

having an adjustable section and ensuring the desired spraying. These

techniques provide greater opportunities for developers in designing heat

engines for new-generation aircrafts, and improve the world market position of

manufacturers, creating the faultless popular high-quality science-based

products for supplying the combustible media.

The rationale for selecting the solution of the posed

tasks

The developed new techniques and devices [1,2] have

shown that the application of combined processing methods with inducing an

electrical field allows to shape the flow channel of sprayers not only by

increasing the area of flow sections, but also by reducing this parameter

through growing the high-grade layer in small-sized holes. This provides the

required stability of air-fuel mixture consumption within a single multijet

sprayer and during the combined work of several sprayer types, located on a

single firewall.

The solution to the problem of shaping the flow duct

of sprayers with a variable section and profile was made possible through the

contact-mechanical method, by adjusting the electrical field energy in process

of cathode coating deposition, or by local anodic dissolution of the

small-section channel material. It proved advisable [3,4,5] to adjust the spray

coverage by using the dimensional processing, which is performed by altering

the edge geometry at the jet inlet/outlet, due to individual shaping of

transitional channel zones in separate sprayers and their combinations located

on a single firewall. The variation in removal and deposition of material,

occurring during combined processing, has been attained by regulating the

amount of electricity with regards to processing time for each channel, and

also by reasonable setting of fixed and variable speed of zone processing for

small-section channels.

The new technological equipment [6,7] has been developed for

implementing the proposed methods of electrical processing. It is shown that

the performance of the technological operations for improving the flow duct of

engines is possible with using modern equipment and means of automatization (including

the imported ones), purchased by Russian enterprises.

The new

methods and devices for regulating the flowing of the operating media in

sprayers

In the manufacture of sprayers (especially, the multijet ones), working

together on a single fire board, it is necessary to ensure the required

consumption of air-fuel mixture and the appropriate angle of spraying.

The consumption is largely determined by the flow section area of the

channel supplying the air-fuel mixture to the combustion zone. For this purpose

it is required to either increase or reduce the diameter of one or several

holes. As a rule, the expansion of flow sections is carried out by

electrochemical processing using the profile metal tool in small-section

channels, given the limited ability of an electrode to pass through the

transitional “trunk channel” section. To implement this method, it has been

proposed to apply the tensile force of not more than half the yield strength to

a thin wire serving as an electrode, in order to prevent short circuits between

the electrodes [4,5].

The previously known processing methods do not allow to reduce the area

of the channel for supplying the air-fuel mixture. The article proposes the

method and tooling for producing high-quality coating (of tenths of a

millimeter thick) in deep holes. For this purpose, the chromium-plating

technique [5,6] is used, which is developed by Voronezh scientists and

performed with a special tool, shown in fig. 1.

Fig. 1. The tool for nanocoating deposition in

small-section holes (as exemplified by a sprayer)

1

– sprayer hole; 2 – tool electrode

(conducting wire); 3 – burnishing belts; 4 – operating medium (electrolyte); 5

- coating; Ð – the force of tool movement in the hole

The developed mechanism of controlled coating deposition on the side

surface of small-section channels made it possible to justify the speed of

electrode movement along the hole, and create the methodology of calculating

the technological modes and tool parameters for combined galvano-mechanical processing.

The most complicated task is to control the spray of burning gas-liquid

combustible mixture with variable, poorly regulated parameters and at high

differential pressure, modifying the gas filling pattern and other jet

parameters in the sprayer channel [8,9]. The eddy flows observed at the nozzle

section can be altered by creating the transitional zone at the rounded nozzle

channel section.

The conducted research has shown that, in the case of small jet

cross-sections, the pulsing flow must conform to regularities according to

which the pulsating motion of multiphase medium is characterized by the

emergence of single or double vortex.

The numerical calculation methods (with significant tolerance) allow to

create the pattern of vortex, generated by compression shock at the nozzle

section, and provide a qualitative description of air-fuel mixture movement

along the edges of the spray cone. It

is shown, that vortex parameters depend on the edge rounding radius which can

only be found by controlled electrochemical dimensional processing.

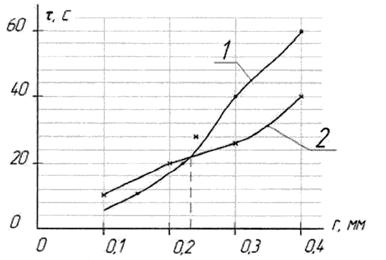

The fig. 2 presents the scheme of transitional zone

formation by radii the value of which depends upon processing time.

Fig. 2. The scheme of edge rounding radius formation

at the section of a sprayer

à) – general view; b) – the dynamics of radius

formation (/, II, III);

1 – sprayer hole; 2 – tool electrode; r1 ,r2 , -

rounding radii, S0 – the initial interelectrode gap

The mechanism for managing the process of preset radius formation may be

implemented under the following assumptions:

·

The removal of metal from the edge has a local character, which

allows to assume that the resulting edge rounding radius closely corresponds to

the circular segment.

·

The current, supplied for anodic dissolution, is concentrated on

the edge during the whole period of processing. The more rigorous description of anodic dissolution assumes not only

the current concentration on the edge, but also its dissipation over the outer

surface of a sprayer, close to the hole. In this case, the quantitative

indicator of current density will be variable, depending on the edge rounding

radius value (r1 > r2

as shown in fig.2). However, this assumption is quite reasonable, in view of

small change in the radius, typical for conditions of sprayer

customization.

·

The removal of metal from the edge is performed along the bisected

line of the angle.

The initial conditions are as follows:

·

The processing is performed in accordance with the scheme

comprising fixed electrodes;

·

The same interelectrode gap (S0 as shown in fig. 2) is set for all edges during their

customization;

The requirements are known, which specify the value of

the edge rounding radius, set experimentally depending on spraying necessary

for each channel.

The boundary conditions are as follows:

·

The variation of the edge rounding radius is within narrow limits

and does not exceed 0.1 mm for edges of small-section holes.

·

The edge rounding radius has

the same value along the edge length (within tolerance) ;

In this case, the control

parameter of edge rounding radius formation (r) will be the processing time,

defined by the formula (1)

![]() (1)

(1)

where ![]() is the density

of the material processed,

is the density

of the material processed,

![]() is current

output

is current

output

![]() is the

electrochemical equivalent of the material processed

is the

electrochemical equivalent of the material processed

![]() is the

conductivity of the process medium

is the

conductivity of the process medium

![]() is the

electrode voltage

is the

electrode voltage

![]() is the loss of

electrode voltage in the interelectrode gap

is the loss of

electrode voltage in the interelectrode gap

The speed of electrolyte pumping

through the gap must be not less than

(2)

(2)

In this case, ![]() is kinematic

viscosity,

is kinematic

viscosity,

![]() is the density

of treatment products (not more than 2.5∙10-3 g/mm3)

is the density

of treatment products (not more than 2.5∙10-3 g/mm3)

![]() is the concentration of treatment products on the edge

(Cα = 0.95 – 0.97)

is the concentration of treatment products on the edge

(Cα = 0.95 – 0.97)

![]() is the concentration of treatment products at the

inlet (Câõ = 0.04 – 0.05)

is the concentration of treatment products at the

inlet (Câõ = 0.04 – 0.05)

![]() is the

coefficient of treatment product diffusion in the flow

is the

coefficient of treatment product diffusion in the flow

![]() = 0.96 ∙

10-3 [1+0.03 (T −273)], (3)

= 0.96 ∙

10-3 [1+0.03 (T −273)], (3)

where T is the average

temperature of electrolyte.

The electrolyte pressure (P)

in the vicinity of the edge must ensure the flow speed, calculated using (2).

With certain tolerance, the value P can be derived from the following

dependence:

![]() (4)

(4)

where

![]() – is the dynamic viscosity of

the medium

– is the dynamic viscosity of

the medium

The

time necessary for obtaining the required edge rounding radius closely

corresponds to experimental results (fig.3), since the radius tolerance is up

to 1/3 of its nominal value.

Fig.3

The processing time, required for rounding the edge by the radius ![]()

![]() = 0,1 mm,

= 0,1 mm, ![]() = 5,3 m/s, the workpiece

material is copper alloy, the electrode voltage is 9 V.

= 5,3 m/s, the workpiece

material is copper alloy, the electrode voltage is 9 V.

1

– the calculated dependence, 2 – the experimental dependence

Conclusion

On the basis of patented methods and

devices, the technology has been developed for customizing the channels by

combined methods with inducing an electrical field in various types and

combinations of sprayers, used for supplying gas-liquid mixture, which allowed

to implement the promising projects of heat engines in conditions of mass

production. The techniques and devices have been created combining the

regulated force actions and adjustable electric fields within a single

technological process for obtaining high-reliability coatings in channels of

various sections (with an area of less than 1mm2) that was

previously unattainable. The mechanism has been developed to create the local

channel zones (also involving the formation of a Laval nozzle profile) with a

section area of less than 1mm2, and the system of controlling the

technological modes of combined processing, in consideration of feedback on

process parameters. This has made it possible to design the technologies of

combined processing and calibration of critical components in the flow section

of single- and multijet sprayers, working individually or as part of fire

boards (walls, bottoms), having sprayers of several typical sizes.

References

1.

Patent ¹ 2303087 Russian Federation, IPC7.The

method and device for local electrochemical processing of channel edges

(Authored by V.G.Gritsyuk, V.P.Smolentsev, I.T.Koptev et al.) "The

Bulletin of Inventions". ¹ 20, 2007.

2. Patent ¹ 2333821 Russian

Federation, IPC7.The method of electrochemical dimensional

processing and the device for its implementation (Authored by V.P.Smolentsev et

al.) "The Bulletin of Inventions" ¹ 26, 2008.

3. Patent ¹ 2470749 Russian Federation, IPC7. The method of

electrochemical processing of local zones and the device for its implementation

(Authored by I.T.Koptev, V.P.Smolentsev et al.). "The Bulletin of

Inventions" ¹ 2 36, 2012.

4.

Norman A.V. The analysis of methods, used

for customization of small-section channels

// The non-conventional methods of processing: the collection of

scientific works. Moscow: Ìàshinostroenie,

2006. Issue. 8, 4.1- PP. 218 - 224.

5. Norman A.V. The adjustment of the diameter size of small-section holes

by coating deposition // The Production of Special Equipment: the

inter-university collection of scientific works. Voronezh: VSTU, 2004. - PP. 50

- 54.

6.Chizhov M.I.

Galvano-mechanical chroming of machine components [Òåxt] / M. I. Chizhov, V.P.Smolentsev // Voronezh: VSTU,

1998. -162 p.

7.

Norman A.V. The equipment for producing the small

diameter holes // The non-conventional methods of processing: the

inter-university collection of scientific works; Voronezh, VSTU, 2005. Issue 7.

– PP.119 - 125.

8.Êîptev I.I. The production and configuration of sprayers for supplying the

combustible mixtures / I.I.Koptev, V.P.Smolentsev, E.A.Saltanaeva // The

assembly in instrument-making and machine construction. - 2013. - ¹1 - PP. 3-7

9. Êîptev I.I. The control of manufacture and customization

of sprayers // A student. A specialist. A professional. - 2013: The proceedings

of the VI international academic and practical conference. - Voronezh: The

Centre of Scientific and Technical Information, 2013. - PP. 182-183.

Credits:

Smolentsev Vladislav Pavlovich – Doctor of Technical Science, Professor, Voronezh State Technical University. Business

address: VSTU, 14, Moskovsky Prospekt, Voronezh, 394026 Òel.9036559970. E-Mail: vsmolenHYPERLINK

"mailto:vsmolen@inbox.ru"@inbox.ru

Smolentsev Vladislav Pavlovich – Doctor of Technical Science, Professor, Voronezh State Technical University. Business

address: VSTU, 14, Moskovsky Prospekt, Voronezh, 394026 Òel.9036559970. E-Mail: vsmolen@inbox.ru

Safonov Sergey Vladimirovich –

Candidate of Pedagogical Science, Professor, Voronezh State Technical

University. Business address: VSTU, 14, Moskovsky Prospekt, Voronezh, 394026

Êîptev Ivan Ivanovich, postgraduate, Voronezh State Technical University.

Business address: VSTU, 14, Moskovsky

Prospekt, Voronezh, 394026