UDC

622.343.9

NEW CYANIDE FREE TECHNOLOGY FOR ELECTROCHEMICAL

EXTRACTION OF GOLD FROM SULFIDE ORES

Candidate of technical sciences, senior researcher,

associate professor Oryngojin Ye. S.

Kazakhstan,

Almaty

Mining

Institute after D.A.Kunaev

Development of gold-mining industry of Kazakhstan is connected with the

insufficient involvement of sulfide ores in mining and processing, which are

complex in composition and persistent in gold extraction. Technologies of

sulfide ores processing applied at Kazakhstan plants are distinguished with

high material W labor costs; they are multi-operational and not environmentally

safe. Therefore, search and creation of new effective technologies for

gold-containing ore processing is exceptionally important economic assignment.

With the view of solution of this problem, the National Engineering

Academy of the Republic of Kazakhstan has developed new electrochemical,

cyanide free technology for gold leaching from persistent sulfide-containing

raw material. The technology has successfully passed a stage of semi-industrial

tests resulting in the production of gold in the solution by means of the plant

manufactured in Stepnogorsk city. The next stage of development was the

elaboration of technology for gold extraction from sulfide-containing raw

material by combining the processes of electrochemical leaching and sorption in

one technological device.

The idea of combination included the creation of U-shaped

electrochemical reactor, in which one branch is separated for cathode and anode

chambers with interelectrode cation-exchange partition, and the other branch of

the device is designed for airlift mixing of the ore grinded till the class

0,074 mm in 20-30% sodium chloride solution. At that the process of

electrochemical gold leaching and sorption is combined with the gold

concentration on the cathode covered with coal fiber.

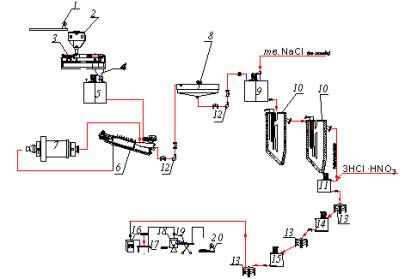

To implement the idea, the flowchart and the chart of its hardware

design have been developed. Hardware chart including two consequently working

U-shaped devices for electrochemical sorption gold leaching is shown in the

picture 1.

Beforehand, the studies by means of devices of box type have been

realized.

The operation of devices of electrochemical leaching of box type with

the use of cation-exchange membranes for the separation of cathode and anode

chambers revealed the opportunity of their application, but in short-term

operation – in pulp environments the membranes turned out to be short-lived and

in several cycles showed cracks in the membrane MKK-1.

The gold came to the cationite into the cathode chamber separated from

the anode chamber with the ion-exchange membrane only in the form of anion

complex and the process rate was limited by the ion diffusion rate through the

cation-exchange membrane that led to the increase of leaching time. The pulp

after the electric treatment was discharged from the anode chamber, i.e. from

the place where gold proper transformed into solution that stipulated the

multi-stage process of the electrochemical leaching.

Based on the experienced gained, basically new structure of

interelectrode partition was developed. The partition consists of two corrosion

plates, in each of which holes are drilled angularly. Hydrogen extracted at

cathode, chlorine at anode, as a result of electrochemical reaction, in this

case cannot arbitrarily mix with each other any more, since the inclined holes

result in the limited access to the zone of opposite sign; recovery of oxidized

gold with hydrogen is minimized. At the same time, relatively free access for

the pulp from one chamber to another is ensured, that leads to involvement of

the whole volume of the pulp in the electrochemical process and helps to

discharge the de-gilded pulp from any chamber.

1- scales; 2 - bunker; 3 - auger feeder; 4 - chute;

5 - conditioner; 6 - sizing screen; 7 - mill; 8 - thickener; 9 - repulper; 10 –

device for electrosorption leaching; 11 - reactor; 12 - pump; 13 - nutsch

filter; 14 – settling tank; 15 - arrester; 16 – tempering cabinet; 17 -

burdening table; 18 – gold-melting oven; 19 - mould; 20 – laboratory scales

Picture 1 - Hardware chart of electrochemical,

sorption gold leaching

As an anode, graphite was used, as a cathode, coal-fiber material based

on graphite with the cover made of filter fabric. Such structure of cathode was

explained by the need to regularly regenerate it. The cover made of filter

fabric ensuring free access for solute gold to a cathode hinders the ingress of

particles of ore material that significantly facilitates the process of regeneration

of coal fiber.

The first test pachuca for electrochemical leaching was remade in

conformity with the idea described above; cathode and anode chambers were

equipped with new partitions and established at one branch of the U-shaped

device, and the second branch served for the airlift mixing of the pulp. The

total volume of both branches of the device is – 200 dm3.

The second 250 dm3 device was made of polyethylene pipe, 330

mm in diameter. The laboratory tests proved the efficiency of use of coal fiber

as a cathode that allowed the simplification of the gold extraction flowchart.

The process of ion exchange gold extraction for ionite resins with numerous

auxiliary operations for resin cleaning from the sludge and regenerating

solution was need no more. There was no need in the assembly for preparation of

desorption solution, in the use of sizing screens to separate the resin before

and after desorption etc.

To carry out the tests, sulfide raw material containing 11,0 g/t of gold

was used – tails of gravity concentration of sulfide ores of “Altyn Alyans – 3”

Ltd in amount of 2 t.

Semi-industrial test of the new technology was carried out in the

following regime:

Voltage – 4,2 – 4,6 v;

Anode current density – 780-820 à/m2;

Pulp density – 1,35 kg/dm3;

S:L Relation = 1 : 3;

NaCl concentration – 200 – 220 g/dm3;

Duration of electrochemical treatment is 6 – 8 hours.

During the test, the value pH

was noted at the output of pulp. Pulp sampling was taken every hour and was

averaged for 8 hours; the averaged sample was analyzed for gold content.

As a coal cathode, coal fiber of the class ÍÒÌ –

100 was used. The current was supplied to the coal fiber through the graphite

framework on which the coal fiber was coiled and then glass fiber cloth.

Consumption of coal fiber per every cathode was 20 g. The results of the tests

are given in the table 1. They show that: concentration of gold in liquid phase

of waste pulp at the output from the second pachuca is 0,02–0,03 mg/dm3,

that corresponds to 99,5% of its extraction. The results of the tests showed

that involvement of one or two additional pachucas in the process flowchart

ensures an opportunity to minimize the loss of gold in the liquid phase.

During the first series of tests at the duration of electrotreatment of

8 hours, the residual content of gold cleansed cakes amounted to ~ 1,7 g/t,

that corresponds to 84% of gold extraction. Reduction of process time till 5

hours results in reduction of gold extraction by 9-10%.

The use in the tests relatively poor raw material did not allow the

achievement of maximum capacity of electrocoal – the coal cathode with the

capacity of 22 g/kg of gold was separated for regeneration. The rest of the

gold was most probably left as a material in process.

Coal cathode was washed with water to cleanse from sludge, was

dismantled from the graphite framework and treated with aqua regia at S:L

relation = 1:5. After this treatment the coal fiber was washed with water, the

wash water was mixed with gold-containing eluate, diluted with water by ~1,5 –

2 times. After the solution was settled during one hour, the sediment of the

liquid phase was separated by means of the filtering. Out of the filtrate, the

coffee like gold-containing sediment was extracted by means of treatment with

the sodium sulfite; and then by means of melting 0,35 g of gold was produced.

The analysis of the remnants of the coal fiber after its treatment with

aqua regia and washing with water showed that they contained up to 8 g/kg of

gold. Relatively high residual capacitance of coal fiber proves the

advisability of its direct treatment by means of burning and consequent

extraction of gold from the ash, since the operation of cleansing of coal fiber

from the sludge is quite labor intensive.

In whole, generalizing the results of the research of the developed

technology, it is possible to state that the chart of combination of operations

of electrochemical leaching and electrosorption with the use of coal fiber

material is quite effective and operative and after certain upgrade can be

recommended for implementation in industrial practice of gold production.