Influence of different modes

on the strength characteristics AGING ALLOY 47 HNM

Mukazhanov Ye.B.1

Telebayev Ye.Ye.2

Takenova G.D.3

Tynaliev Bauyrzhan4

1 Doctoral

Student, PhD, Associate Professor, Academy of Economics and Law, Zhetysu State

University. I.Zhansugurov, Taldykorgan, Kazakhstan

Taldykorgan

Polytechnic College

2 Taldykorgan

Polytechnic College

3 PhD, Associate Professor, Taldykorgan Polytechnic College

4 Taldykorgan

Polytechnic College

Taldykorgan,

Kazakhstan

One

of the important operations in the general cycle of heat treatment

precipitation-hardening alloys hardening is aging as a result of which not only

increases the strength properties, but also vary greatly and many physical

characteristics. As you know, the main processes occurring during aging is the

decay of supersaturated solid solution with the release of a new phase,

different from the original matrix, in general, not only the chemical

composition but also the structure. Since the collapse of the quenched alloy is

a diffusion process, the degree of decomposition, and the form of precipitates,

their dispersion, and other structural characteristics depend on the

temperature and duration of aging, the nature of the alloy and its chemical

composition, in addition, the structure and chemical properties of the alloy

aged affected by temperature heating and cooling rate during quenching and many

other factors. That is why the study of aging precipitation-hardening alloys

devoted significant amount of research, and interest in this research does not

weaken and beyond. The dependence of mechanical properties (elastic limit,

yield and tensile strength) of the structure and more factors, as well as

multi-stage process of decomposition of hardened alloy, combined with high

dispersion of emissions, especially in the early stages of aging, it very

difficult to study these characteristics with age. In most cases, to explain

many effects observed with aging, attracted by x-ray and electron microscopic

analysis using the method of microdiffraction.

Strength

characteristics and structure defining these properties in a state of maximum

hardening, largely determined by the phase and structural changes that occur in

the alloy 47 hnm in the most initial stage of aging. Therefore, it is advisable

to consider the modes of aging, not only in a state of maximum hardening, and

in a wide temperature range, from low-temperature aging, when the rate of decay

and diffusion processes in general is very low (this case corresponds to the

initial stages of decay) to the stage of the high-temperature aging in charge

mode overaging .

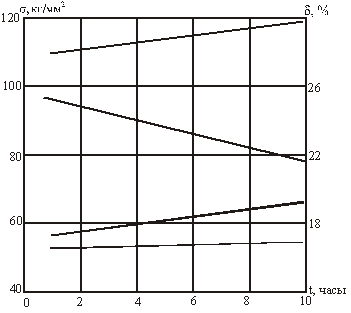

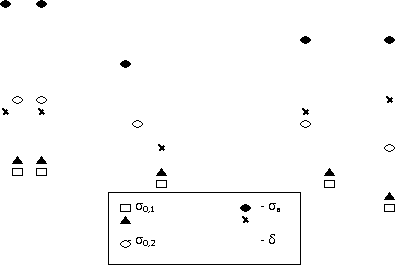

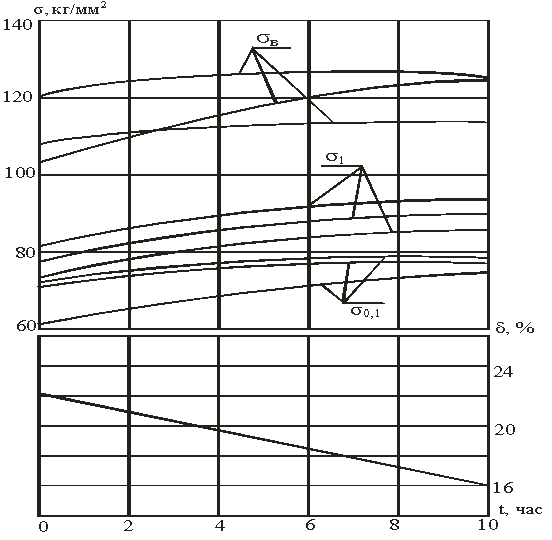

Figure

1 shows the mechanical properties of the alloy 47 hnm based on the time of

aging at 600º C, previously quenched from 1250ºC (exposure time at

hardening temperature was 2 min.) With increasing aging time is a slight

increase in hardening of the alloy, which is consistent with the structural

studies. Comparing the data of structural studies with the change of the

strength properties, it is possible to draw some conclusions, namely the contribution

to the strengthening of the alloy, apparently due only to collapse in the

excess phase, but as the volume fraction of this phase is low (5-10%), and the

amount of emissions within these particles is from 15 to 40 A, the increase of

hardening is very small. Within the matrix of any structural changes from

hardened material occurs (up to 10 hours of aging), and therefore its

contribution to the strengthening of the alloy can be neglected. Some drop of

plasticity is likely due to formation of segregations of alloying elements on

grain boundaries.

In

fig. 1 and 2 shows the kinetics of hardening of the alloy at 700º C,

pre-tempered at 1250º C. In the initial stages of aging is already marked

increase in resistance to small plastic deformation, the value of which

increases sharply with further increase in aging time. The observed increase in

hardening stage of decomposition is responsible, resulting in rapidly

developing decay, emitting incoherent α-phase.

Electron

microscopic study of the structure and metallography showed that intermittent

decay starts at the grain boundaries, and ends after 5-10 hours after the onset

of aging, and the volume fraction of the decay is 75-85%, which corresponds to

the maximum hardening. Nature hardening at this temperature aging is caused by

inhibition of dislocations, the separated particles intermittently

α-phase.

Ductility

of the alloy with increasing aging time decreases monotonically decreases to 5%

within 10 hours of aging, while for the quenched alloy was 25%. This decline is

understandable, given the sharp increase in strength. In addition, it should be

noted that the sensors are working in the elastic region with a very low

residual deformation and therefore such a reserve of plasticity is sufficient

for proper function.

Figure

1. - mechanical properties of the alloy as a function of aging time at

600ºC, previously quenched from 1250ºC, 2 min.

Figure

2. - Mechanical properties of alloy 47 HNM based on the time of aging 700

º C, pre-hardened from 1250 º C, 2 min.

Comparing

Figs. 1 and 2, we can see some data scatter in the values of

the yield strength and ductility. This is because the properties of the alloy

in Fig. 1 were obtained on the material, heat-treated at the factory, at the

time, as the properties of the alloy, as shown in Fig. 2 were studied in

another series of fusing material and processed in the laboratory. Scatter in

the data is due not only to different chemical composition of the material and

the heterogeneity of structure, but also the difference in the cooling rate

during quenching. With further increase of the aging temperature, a change in

the behavior of the strength properties of the alloy on the length of aging. In

Fig. 3 shows data on the effect of aging time at 800 º C on the microplastic

deformation resistance, deforming stress and ductility of the alloy 47 HNM.

First of all, it should be noted that in the initial stage of aging, the flow

stress and especially the yield stress has a value which is not conceding the

properties of the alloy aged at 700 º C. Therefore, this mode is

recommended for the production of elastic sensors, as this significantly

reduces the time of the heat treatment. With increasing aging time gave

strength and other flow stress, including tensile strength decreases, due to

the beginning of the coagulation process in the cells of the intermittent

collapse, at 100 hours aging sferoidezatsy slats α-phase. At the same time

there is a growth of plasticity, ie dislocation that occurred during

deformation, it becomes easier to overcome obstacles in the idea of large

coagulated particles of α-phase. Thus, the reduction of strength

properties and increased ductility perestarenii alloy caused by the increase of

distances between the previously formed precipitates due to their coagulation,

reducing the number of particles per unit volume of the matrix and decrease the

voltage required to bypass the particles dislocations. The stated view is

supported by structural studies, it is enough to compare the microstructure of

the alloy aged at 800 º C with the structure of the alloy treated at 700

º C. The intensity of coagulation increases with increasing temperature of

aging, such as at 900 º C or 1000 º C, while also there is a decline

of strength properties. Why spend the final heat treatment - aging in this

temperature range is unreasonable.

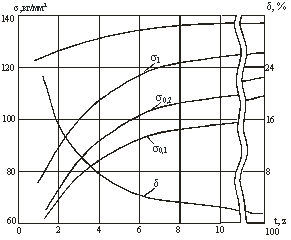

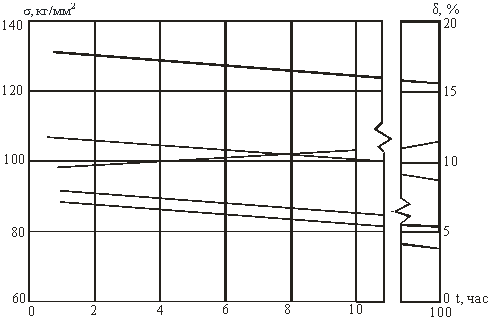

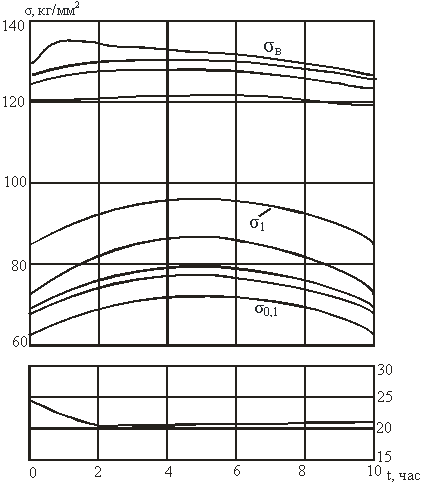

The

dependence of the strength characteristics (τ0,1; τ1; τâ) and

technological plasticity (δ) alloy 47 HNM the length of time of aging,

ranging from 1 hour to 100 hours in the temperature range 600-800 º C is

shown in Fig. 4. The samples were pre-hardened from 1250 º C, for 2

minutes. From the analysis of the picture hardening alloy in this temperature

range, it can be concluded that the yield stress, as well as other flow stress,

reaches a maximum at 600 and 700 º C, for 100 hours of aging, with the

largest increase in hardening is observed at 700 º C. However, this aging

time is impractical in the factory, because of the great length of the heat

treatment, the nature of changes in the structure and strength properties of

the alloy in the temperature range investigated is also confirmed by the data

of [3].

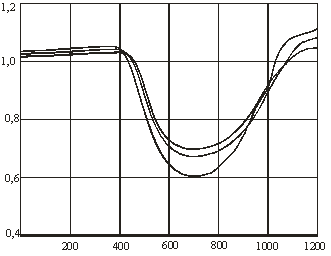

As

an example, the change in the electrical resistivity of the annealing

temperature and annealing, the variation of which is shown in Fig. 5 and 6.

Thus, for high strength with minimal elastic imperfections heat treatment of

the alloy must be conducted in the temperature range 650-750 º C, and the

aging time should be between 10 to 20 hours, decreased with increasing

temperatury.Kak known quenching temperature determines the level of strength

properties, with further aging. For example, a higher hardening alloy of 36

NHTYU in aging is achieved after low-temperature tempering (930-970 º C)

compared with quenching at 1100-1250 º C. This effect of heating

temperature, due to the change of state of the grain boundaries, which

determines the nature of the decay (continuous or intermittent) in the

subsequent aging. However, in the beryllium bronze increasing quenching

temperature, increasing the degree of homogeneity of the solid solution as the

concentration and reduction of defects of the crystal lattice structure holds

the higher strength properties [1, 2].

Figure 3. - Mechanical

properties of alloy 47 HNM based on the time of aging 800 º C,

pre-hardened from 1250 º C, 2 min.

Hardening temperature.0Ñ

![]()

Figure 4. - The dependence of the electrical resistance of the alloy

47HNM temperature quenching. Initial state - cold deformed, 75% degree of

deformation and aging II H; 2-5 hours, 3-10 hours

á á c d b à

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Figure 5. - The relationship between the strength

characteristics (, σ1-, σv -, δ -) alloy 47 HNM of aging

temperature, pre-hardened from 1250 º C, 2 min., A) - 1 hour, b) - 5

hours) - 10 hours, Mr. ) -1000 hours.

![]()

á á á

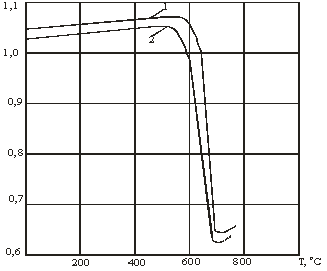

Figure 6. - The dependence of the electrical

resistance of hardened alloy 47HNM of tempering temperature. Initial state:

1-quenching from 1250 º C 2-quenching from 1300 º C.

Therefore, is not only of

theoretical interest to investigate the effect of quenching temperature on the

degree of hardening of the alloy 47 HNM the decay of supersaturated solid

solution.

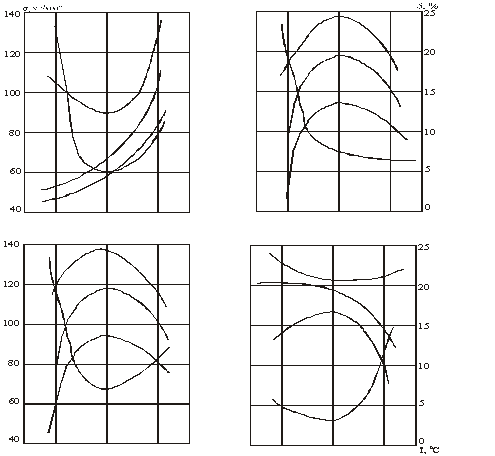

In Fig. 6 shows the mechanical

properties of the alloy 47 HNM based on the time of aging, previously quenched

from 1000 º C. Exposure time during quenching is from 1 to 10 hours.

Analysis of mechanical properties shows that the yield strength and the

strength and flow stress corresponding to 1% residual strain change on the

curve with a maximum. Maximum strength is reached after five hours of aging and

to further develop softening process, leading to a drop in the mechanical

properties.

Hardening of the alloy in the

initial stages of aging is due to a relatively high degree of dispersion of the

structure (dispersion structure in this case should be compared with later

stages of aging at this temperature), the relatively small size of the

particles of α-phase and small interparticle distance, which effectively

prevents the movement of dislocations. In perestarennom material (the

descending branch of the curve) because of the processes koalesnentsii

sferiodizatsii and a marked decrease in strength properties. If you compare the

level of properties after quenching from 1000 º C and higher temperatures,

such as 1250 º C at the same time and temperature of aging, we can see a

significant reduction in the first case hardening. This difference at 700

º C and up to 15 hours of aging kg / mm.

Character marked reduction of

strength properties with decreasing quenching temperature is due, apparently,

low supersaturation matrix alloying component. The stated point of view also

finds support in the analysis of the variation of hardening of the alloy aged

at the time of exposure quenching from 1000 º C. From Fig. 7 shows that as

the firing time (from 1 to 10 hours) at a temperature of quenching and

subsequent aging at 700 º C the strength properties fall, though the

faster, longer heating time and minimum values they

reach the samples, kept at a temperature hardening for 10 hours. The fall of

the properties (τ0, 1) the transition from one hour to 10 hours of

annealing is 85 kg / mm to 70kG/mm2 respectively.

Figure 7. - Mechanical properties of the alloy 47HNM

depending on the time of aging at 700 º C, pre-hardened from 1000 º

C: -1 hour-2 hours, 5 hours, 10 hours.

Ductility of the alloy (graph of the plasticity of the

aging time is shown in the lower part of Fig. 7) for thermal treatment of

almost constant and only decreases depending on the aging time, and the

greatest rate of decrease is observed for the first two hours of aging.

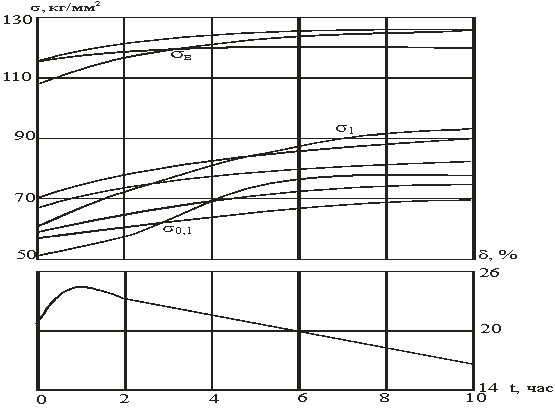

In Fig. 8 shows the dependence of the mechanical

properties of the aging time of samples previously quenched from 1050 º C

for 1, 2, 5 and 10 hours. In contrast to the material, quenched from 1000

º C a distinct stage overaging in this case is not observed. This is shown

by the curve plasticity chart of which is shown in the lower part of the

figure. Plasticity in this case decreases monotonically, decreasing from 22% to

16%.

Figure 8. - Mechanical properties of the alloy 47 HNM

based on the time of aging at 700 º C, pre-hardened from 1050 º C: -

1 hour - 2hours - 5hours, 10 hours

Further increase of the quenching temperature to 1100

º C in order to achieve maximum strength properties, with subsequent aging

at 700 º C does not reach the target (Fig. 9). Although the values of

mechanical properties are slightly higher than in previous treatments (ie 1000

and 1050 º C), to reach the level of properties that meet the hardening

behavior in 1250 º C, 2 min, and the aging of 700 º C, 5h fails.

Not yet received an explanation of

the nature of plasticity changes depending on the time of aging, because there

is not any correlation in the change of the strength and plastic properties.

The

structural studies, as no public explanation for the appearance of the maximum

on the curve of plasticity.

When comparing the mechanical

properties of the alloy 47 HNM quenched from 1250 º C (Fig. 2) and the

properties of the alloy, tempered at lower temperatures (Fig. 7, 9) that the

values of the deforming stress in case hardening at 1250 º C is

significantly higher than that of quenched samples in the temperature range

1000-1100 º C.

Thus, with increasing quenching

temperature during subsequent aging of the strength properties of the alloy are

growing, and in fact more so the higher the temperature quenching. The same

effect was observed at 1300 º C, but low technological properties not

possible to recommend this mode for use in the production of elastic sensing

elements ..

Figure

9. - Mechanical properties of the alloy 47 HNM based on the time of aging at

700 º C, pre-hardened from 1100 º C: - 1 hour - 2hours - 5hours, 10

hours.

In conclusion, it should be noted

that at the present time in our laboratory developed more sophisticated methods

of heat treatment, allowing not only increase the strength of the alloy 47 HNM,

but also to improve processing properties, while reducing the time of heat

treatment. Such methods of processing, for example, is a step aging, including

low-temperature treatment at the first stage of aging and the subsequent

high-temperature processing in the second stage of aging.

literature

1.

Precision alloys. Spravochnik.Pod red.B.V.Molotilova.M.,

"Metallurgy", pp. 368-371,1974

2.

A.G.Rahshtadt. Spring steels and alloys. M., "Metallurgy", 1971.

3.

Zh.P.Pastuhova, A.G.Rahshtadt. Medi.M. spring alloys, "Metallurgy",

1979.

4.

TV Krasnopevtsev RM Paretskaya, GG Knyazev. Sat "Modern spring alloys,

processing and testing, Part 1. LDNTP, page 15, 1967. "

5.

TV Krasnopevtsev RM Paretskaya. Physical and mechanical properties of

corrosion-resistant alloy 47 HNM with high elastic properties. In Sat Tr.

TsNIIChM: Precision alloys. M. "Metallurgy" no. 64. pp. 90-99, 1968.