Технические

науки \ 8. Обработка материалов в машиностроении

Goncharenko V.V., Mikulenok I.O., Goncharenko M.V., Gerasimov G.V., Martynenko N.M., Shvachko D.G.

The National Technical University of Ukraine

“KPI”

Temperature tailored sensor-actuator

on a basis of the shape memory metal reinforced polymer matrix composites

The study

of the shape memory materials is the “hottest area” in current research [1].

One of the uses of these tailored materials is in fire-fighting systems [2].

Such materials may be of different types, depending on the use to which they

are put. If the metal reinforced polymer matrix composite materials can be

tapped, there would be a promising source for the fire-fighting systems [3].

Matrix

compound of such composites can be prepared from the linear polyethylene which

has a high fluidity limit of melt. Lowering of the temperature threshold sensibility

is achieved by an increase of paraffin concentration in matrix compound. Such

tailored composite materials for predetermined temperature threshold sensibility

hold the greatest promise for increased fire safety. The integration sensor’s

and actuator’s properties has made it possible to refuse from electric reverse

communication. The abandonment from the electric reverse communications has

made it possible to arrive at the higher degree of reliability of the

fire-fighting systems.

The

straightened metal springs are used as the reinforced element. If temperature

of these tailored sensor-actuators arrives at the temperature threshold sensibility,

the straightened metal springs due to shape memory effect make a demonstration

of partial shrinkage. Such primary thermal shrinkage initiates sharp collapse

of stress in the reinforced springs close to level of the high fluidity limit

of the polymer compound melt. Lowering of the fluidity limit of the polymer

matrix compound melt stimulates more complete thermal shrinkage of the

reinforcing metal springs in a moment of achievement of the temperature

threshold of sensibility.

The goal

of our study is receiving of more complete thermal shrinkage of the metal

reinforced polymer matrix composite materials in a moment of achievement of the

tailored temperature threshold of sensibility.

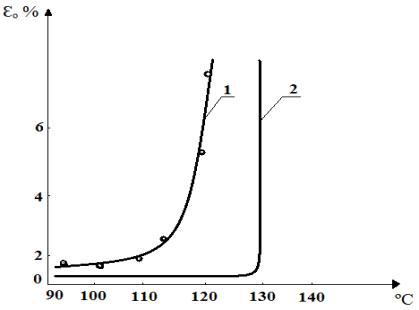

Utilization

of polyethylene designed for rotation molding LLDPE M3804 RWP (produced by

SCG-Chemical in Thailand) permits to the most lowering of the fluidity limit of

the polymer matrix compound melt. For reference, two thermo mechanical curves

of different polyethylene are (of great importance for) plotted in the same

figure 1. As will be seen from the diagrams, the polyethylene LLDPE M3804 RWP

is characterized by a sharp lowering of a stress resistance. This is in general

agreement with the very little fluidity limit of the polymer melt.

Any melt

temperature of this polymer matrix compound is function of a paraffin

concentration. Such melt temperature ![]() depends on paraffin

concentration

depends on paraffin

concentration ![]() in following manner:

in following manner:

![]() ,

,

where ![]() is melt temperature of the polyethylene LLDPE

M3804 RWP:

is melt temperature of the polyethylene LLDPE

M3804 RWP: ![]() K;

K; ![]() is material constant:

is material constant: ![]()

Concentration

within this matrix compound can be raised to get to 0,175 of the paraffin. The

melt temperature of the polymer compound in this situation must be equal 680C.

The complete thermal shrinkage of such metal reinforced polymer matrix

composite material at 680C is quite important for the purposes of

the fire-fighting.

Fig.1.

Thermo mechanical curves: 1 – low density polyethylene 15803-020 (Novo-Pollock,

Belarus); 2 – polyethylene LLDPE M3804 (produced by SCG-Chemical, Thailand); ![]() is

relative deformation, %;

is

relative deformation, %; ![]() is temperature, 0C.

is temperature, 0C.

References:

1. Shahinpoor,

M., Shneider, H.-I. Intelligent Materials // Tomas Graham House, Science Park.

Royal Society of Chemistry. Cambridge, UK. 2008.

2. Chu, Y.Y.,

Zhao, L.C. Shape Memory Materials and its Application // Preceding of the International

Conference on Superelastic Technologies and Shape Memory Materials // USA.

2001.

3. Goncharenko,

V.V., Loboda, P.I., Goncharenko, M.V., Yakovlev, M.A. Application of the metal

reinforced polymer matrix composite in the sprinkler fire-fighting systems // Science

bulletin of the National Polytechnic University of Ukraine. Series “Chemical

engineering, ecology and care of resource”. No.1. 2010. Pp. 42-43 (In Russian).