Ekaterina Lozovskaya, Sergey Balabaev, Konstantin

Rumyantsev

Southern Federal University

105/42 Bolshaya Sadovaya Str., Rostov-on-Don, 344006, Russia

The mathematical model of the recording video camera for the height

measurement of the regularly situated objects.

The

priority direction in the â

domain of noncontact measuring of geometric object’s parameters is the creation

of the telemetric control systems, admitting to find the image of the measuring

objects using the video camera and to make their analysis by the digital signal

processing methods on the personal computer base [1].

One of

the fundamental directions in the atomic energetic is the creation of the

high-reliability informational managing complexes, as far as the use of the

superannuated manage systems of the

technological process vastly reduce the effectiveness of the nuclear power

plant(NPP). [2].

The index having an influence on the safety of the realizing dangerous nuclear labors is the

height of the fuel assemblies’ heads (FA),characterizing

their curvature, which for certain values makes it impossible to

operate the reactor core [3-4]. The main performance criterion of the height’s

control of the heads FA is to minimize the measurement error.

Improving noncontact (visual) method

for determining the height of the nuclear reactor’s heads FA on the basis

of three-dimensional image reconstruction is necessary to improve the accuracy

of measurements.

Known noncontact (visual) method [5]

of the definition the height of the nuclear reactor’s heads FA based on the

reconstruction of three-dimensional images. The method is of the height’s

control based on a series of the consistently produced images of one camera

from different angles, which are then transmitted to a computer for processing.

Method [5] provides for a stereo pair of images in the system at the

exact setting (moving) a video camera to the given point of the space.

In a typical three-dimensional image space the distance information to

the elements of the scene appears only in the form of indirect evidence: in the

relative sizes of the objects, shading some objects by others, different

illumination, etc. One way to obtain information about the height’s objects is

the registering multiple images at different angles scene. In this case, the

points of the scene give the images, the relative position of which depends on

the distance to the observation point. Comparing these images there is

possibility to reconstruct the three-dimensional structure of a scene using a

technique [1, 6].

Feature measurement

the height’s heads FA is to use one camera, and the video camera subsequent

fixation in certain points of space is provided for the creating stereo system.

At that the three-dimensional reconstruction of the scene takes place on two

images from different angles.

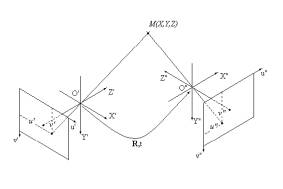

Two cameras located

at different points, record the same scene, but the optical axes of the video

cameras are not parallel and the direction of displacement of the optical

center of the one video camera relative to another video camera’s optical

center arbitrarily (Fig.1).

Fig. 1. The system

of two arbitrarily oriented video cameras

The

purpose of research is to develop a mathematical model of the recording video

camera, which will assess the method error of the measurement of geometrical

parameters due to the imperfection of the measurement method and the

simplifications made by indirect measurements [7-8].

The

proposed model of the imaging enables to establish communication between the

points’ coordinates of the scene and their images, to determine the parameters

of the registration’s system and the three-dimensional structure of the scene

of the group FA [5]. Nuclear reactor fuel assembly can be seen visually as a

"cell" of seven cylinders , and six of them are located at the

vertices of a regular hexagon (positions (1)-(6) in Fig. 2) , and the seventh

is at its geometric center (position (0) in Fig. 2) . The investigate objects

are the regular structure and situated in an aqueous medium in a strictly

defined order. The object’s rods in Fig. 2 are conditionally designated the

points. R is radius of the cell FA.

Fig. 2. Object in

the form of a regular hexagon

In the developed MathCAD model the video camera is CDR

3223 Baxall with lens focal length f = 2, 84 mm, matrix size 1/2 ", and a

definition of 752x582.

The optical center of the video camera is located on a

circle with a radius of rotation D / 2, the center O of which is the rod’s axis

(Fig. 3). It is assumed that the rod’s axis is perpendicular to the plane of

the hexagon at its geometric center (position (0)).

Fig. 3. The video camera fastening

The

height of suspension of the video camera over the “cell” is H and is determined

basing on the coverage of all seven rods field of video camera’s vision. In

this case the optical axis of the video camera also passes through the rod (0)

(Fig. 3).

The

three-dimensional coordinates of the points are specified in the global

coordinate system (GCS), not coinciding with the standard coordinate system of

video camera (SCS) (Table 1).

TABLE I

Coordinates of rods’ points in gcs

|

|

x |

y |

z |

|

p.0 |

0 |

0 |

0 |

|

p.1 |

-0.5 |

0 |

-0.866 |

|

p.2 |

0.5 |

0 |

-0.866 |

|

p.3 |

1 |

0 |

0 |

|

p.4 |

0.5 |

0 |

0.866 |

|

p.5 |

-0.5 |

0 |

0.866 |

|

p.6 |

-1 |

0 |

0 |

Transition

from GCS to SCS is done by turning the coordinate axes system SCS and

subsequent displacement of the origin by a distance L (Table 2).

TABLE II

Coordinates rods’ points in scs

|

|

x |

y |

z |

|

p.0 |

0 |

0 |

2.236 |

|

p.1 |

0.5 |

0.387 |

3.011 |

|

p.2 |

-0.5 |

0.387 |

3.011 |

|

p.3 |

-1 |

0 |

2.236 |

|

p.4 |

-0.5 |

-0.387 |

1.461 |

|

p.5 |

0.5 |

-0.387 |

1.461 |

|

p.6 |

1 |

0 |

2.236 |

In the

standard system, the projections of the three-dimensional points coordinates

are the coordinates in the video camera image (Table 3).

TABLE III

Coordinates of the rods’ points in the image plane of video camera

|

|

x |

y |

|

p.0 |

0,00 |

0,00 |

|

p.1 |

0.472 |

0.365 |

|

p.2 |

-0.472 |

0.365 |

|

p.3 |

-1.27 |

0,00 |

|

p.4 |

-0.972 |

-0.752 |

|

p.5 |

0.972 |

-0.752 |

|

p.6 |

1.27 |

0,00 |

For a

complete description of the video camera is necessary to evaluate the

coordinates of points in the image plane in the natural units of the photo

detector (Table 4).

TABLE IV

Coordinates of the rods’ points in the natural units of the photo detector

(pics)

|

|

x |

y |

|

p.0 |

0,00 |

0,00 |

|

p.1 |

57.182 |

42.89 |

|

p.2 |

-57.182 |

42.89 |

|

p.3 |

-154.003 |

0,00 |

|

p.4 |

-117.847 |

-88.393 |

|

p.5 |

117.847 |

-88.393 |

|

p.6 |

154.003 |

0,00 |

At the

same time a mathematical model allow to

determine the number of pixels, in which each point is (Table 5.6). If the

coordinates do not fall within the photosensitive matrix, the program assigns a

value of zero pixel.

TABLE V

Pixel number of the hexagon points in the system of vc1

|

VC1 |

x |

y |

|

p.0 |

0 |

0 |

|

p.1 |

58 |

43 |

|

p.2 |

-58 |

43 |

|

p.3 |

-154 |

-1 |

|

p.4 |

-118 |

-89 |

|

p.5 |

118 |

-89 |

|

p.6 |

154 |

1 |

TABLE VI

Pixel number of the hexagon points in the system of vc2

|

VC2 |

x |

y |

|

p.0 |

0 |

0 |

|

p.1 |

154 |

1 |

|

p.2 |

58 |

43 |

|

p.3 |

-58 |

43 |

|

p.4 |

-154 |

-1 |

|

p.5 |

-118 |

-89 |

|

p.6 |

118 |

-89 |

The

create of two video camera stereo

system, oriented at an angle of 60 ° (Fig. 4), enables to evaluate the

three-dimensional coordinates of the points of the hexagon in the coordinate

system of any of the cameras.

Fig. 4. Regular hexagon with the planned position of

video camera

At the

same time, having the coordinates of points in the natural photo detector units

in the coordinate system of video camera (VC) 1 (the first camera position) and

video camera (VC) 2 (the second camera position), there is possibility to

calculate the vectors of three-dimensional coordinates of points in the systems

VC1 and VC2 (Table 7, 8).

TABLE VII

Coordinates of the rods’ points in scs1

|

VC1 |

x |

y |

z |

|

p.0 |

0 |

0 |

2.236 |

|

p.1 |

-0.719 |

0.55 |

-4.27*10^-3 |

|

p.2 |

-1.287 |

-0.985 |

7.643*10^-3 |

|

p.3 |

-1.585 |

0.011 |

3.545*10^-3 |

|

p.4 |

-0.712 |

0.554 |

2.079*10^-3 |

|

p.5 |

-1.293 |

-1.006 |

-3.772*10^-3 |

|

p.6 |

-1.576 |

0.011 |

-3.523*10^-3 |

TABLEVIII

Coordinates of the rods’ points in scs2

|

VC2 |

x |

y |

z |

|

p.0 |

0 |

0 |

2.236 |

|

p.1 |

1.573 |

-0.011 |

3.518*10^-3 |

|

p.2 |

1.303 |

-0.997 |

7.738*10^-3 |

|

p.3 |

0.719 |

0.55 |

-4.27*10^-3 |

|

p.4 |

1.574 |

-0.011 |

-3.519*10^-3 |

|

p.5 |

1.285 |

-1 |

-3.75*10^-3 |

|

p.6 |

0.723 |

0.563 |

2.11*10^-3 |

For the

evaluation of three-dimensional coordinates of points on a stereo pair is

necessary to know the internal parameters of video cameras (the calibration

task) and to know the parameters of the mutual arrangement of video cameras

(the problem of relative orientation). After solving these problems in the

images the coordinates of the corresponding data points conjugate points can be

found (the task of finding conjugate points).

Thus,

during the research, a mathematical model of the object, enabling to determine

the coordinates of the points of the hexagon in the global coordinate system

(GCS). There are determined the correlations for the conversion of coordinates

from GCS in SCS with the following displacement of the origin; calculated the

coordinates in natural units photo detector; reconstructed the

three-dimensional coordinates of objects on the basis of SCS coordinates of

their projections in the images of a stereo pair, made a reverse

conversion of coordinates from GCS to SCS .

The

proposed mathematical model enabled to recalculate the coordinates of the

points of the GCS to SCS and the inverse. The relations will assess method

error of measurement of geometrical parameters due to the imperfections of

contactless measurement method or simplifications made during

measurements by reconstructing the three-dimensional scene on a series of

images.

Acknowledgment

We wish to thank the

Department of information security for their insightful comments on earlier

drafts.

References

[1] Methods of computer

imaging / edited by V.A. Soifer - M. :

Fizmatlit, 2001. - 784 p.

[2] Balabaev S.L., Radetzky V.G.,

Rumyantsev K.E. Telemetry control method of the height of the cylindrical

objects. Southern Federal University. Engineering. 2008. T. 80. Number 3. Pp.

94-110.

[3] Balabaev S.L., Radetzky V.G.,

Rumyantsev K.E. Video System contactless control of the height of objects.

Southern Federal University. Engineering in 2006. T. 64. ¹ 9-1. Pp. 157-161.

[4] Korobkin V.V., Korovin Y.S.,

Khisamutdinov M.V., Rumyantsev K.E., Balabaev S.L., Makeev V.V. Contact

detection system of the height of the heads nuclear reactor fuel assemblies

(FA). A utility model patent RUS 103963 22.12.2010.

[5] I.A. Kalyaev, K.E.

Rumyantsev, V.V. Makeev , S.L. Balabaev , V.V. Korobkin , J.S. Korovin , A.P.

Kuharenko , V.G. Radetzky. Non-contact method for determining of the height of

the heads nuclear reactor fuel assemblies on the basis of three-dimensional

reconstruction images /Southern Federal University. Engineering. 2008. T. 80.

Number 3, p.126 -131.

[6] Gruzman I.S., Kirichuk

V.S., Kosyh V.P., Peretyagin G.I., Spector A.A. Manual. Digital image

processing in information systems. Novosibirsk: Publishing House of the NGTU,

2002. - 352.

[7] Rumyantsev K.E., Balabaev

S.L., Zibrov V.A Non-contact measurement of geometrical sizes of rolled

products and steel industry. Shakhty: Publisher URGUES, 2004 - 156 p.

[8] M.L. Lopatin, S.L.

Balabaev. The complex reconstruction of three-dimensional models of objects /

News of higher educational institutions. North Caucasus region. Engineering. -

2011. - With. 9-12.