Korniyenko B.Y.

National aviation university, Ukraine

Characteristics

of the production of mineral fertilizers in a fluidized bed granulator

Community development in modern

conditions depends on the development and implementation of energy efficient

environmentally friendly technologies. Application of technique of fluidization for

obtaining solid composites with desired properties in the presence of

phase transitions allows to combine a number of technological stages by the

thermal coefficient of more than 60%. The creation of mathematical models for

the purpose of creation modern systems of management processes in disperse

systems is relevant [1].

Granulation processes are different both

in the methods of implementation, and in the hardware design. One of the

promising methods is an obtaining of a granular product in a fluidized bed

apparatus.

The aim of the article is to study the

static and dynamic characteristics of the mathematical model of a fluidized bed

granulator during the intensive heat and mass transfer processes in the

manufacture mineral fertilizers.

Feature of the

process of formation of solid humic-mineral composites is uniform distribution

of mineral and humic substances throughout the volume of grain and in physical and mechanical properties:

spherical shape, diameter 1.5 - 4.5 mm, strength ≥ 10 N/grain. This solution

dispersed in two-phase system: granular material - gas coolant.

Liquid phase by the action of adhesive

and sorption forces sticks to the surface of solid particles in a superfine

film. The porous structure of granules causes partial diffusion of moisture. To

films from hot solid particles and gas coolant supplied heat. This leads to

intense evaporation of the solvent resulting in the surface of solid particles

formed a thin layer of microcrystals mineral substance and deposited between

colloidal particles of humic compounds. Further microcrystals serve as centers

of crystallization of minerals with another liquid film, resulting in

increasing the size of granules.

There are several approaches to the mathematical

modeling of dehydration and granulation in fluidized bed.

Granular material is fluidized chaotic

system. For the mathematical modeling of fluidized bed apparatus is also

chaotic hydrodynamics.

Very effective are attempts to explore

the hydrodynamics of multiphase processes in a fluidized bed apparatus using

mikrobalance models. These mathematical models solved to bind the equation of

conservation of energy considering the interfacial interaction. For

multivariate modeling processes of dehydration and granulation in fluidized bed

using two-phase Euler-Euler model.

Transport equation of temperature

granules taken into account convective heat transfer, solid phase voltage, flow

fluctuation energy scattering energy collisions, the energy exchange between

the phases. It is possible to determine the intensity of the interaction of the

gas (solid) environment and solid particles (dispersed phase) at different

hydrodynamic regimes and the corresponding temperature change granules during

dehydration and granulation [2].

Mathematical model [2] fully takes into

account the process, but a large amount of calculation time complicates its use

in driving the process of dehydration and granulation in fluidized bed in real

conditions.

Therefore, use slightly simplified

mathematical model of its structure corresponds to the model described above,

but significantly improves its adaptation in driving the process of dehydration

and granulation in a fluidized bed.

According to the results of experimental

researches it was found that for the kinetics of the process of obtaining a

stable final product with desired physical and chemical properties in fluidized

bed granulation prerequisite is respect given temperature in the layer.

Therefore, to research the static and dynamic characteristics of selected

mathematical model with lumped parameters - the ultimate coolant temperature

and temperature fluidized bed.

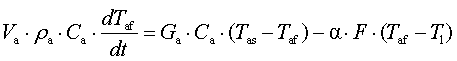

The dynamics of thermal balance coolant-air can

be described by the following equation:

; (1)

; (1)

where Tas,

Taf– initial and

final air temperature, Ê; Tl – temperature

layer, Ê; F– surface mass transfer, ì2; α– heat transfer coefficient, W/ì2·Ê; Ga– air flow, ì3/ñ ; Ca– heat capacity of air, J/kg·Ê; Va– the air volume, ì3; ρa– air density, kg/ì3.

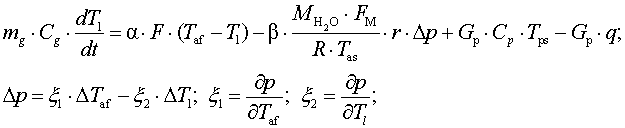

Dynamics of heat balance particle fluidized bed

is described as follows:

(2)

(2)

where β –

coefficient of mass recoil, ì/s; ÌH2O

– molecular weight of water, kg/mol; F

– mass of transfer surface, ì2; FM –

particle surface, ì2; R – universal

gas constant, J/(mol·Ê); mg– mass of

granule, kg; Ñg - specific heat of

the material granule, J/kg·Ê; Gð –

expenditures of solution, kg/ñ; Δð

– difference of partial pressures, Pà; xp

– moisture content of the material; Òðs

– initial

temperature of the solution, Ê;Ñð -

heat capacity of solution, J/kg·Ê; r– heat of vaporization, J / kg; q - heat

released by crystallization solution, J/kg.

Possible channels

"expenditures coolant-temperature fluidized bed", "cost solution

- temperature fluidized bed."

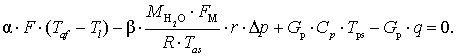

For static characteristics are equation

based finite temperature and the temperature of the layer changes the air flow

and solution:

![]() ; (3)

; (3)

(4)

(4)

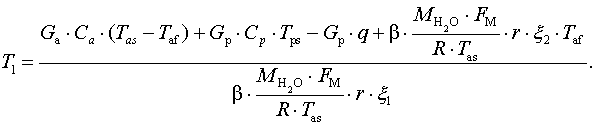

From equations (3) - (4)

we obtained an expression for the temperature fluidized bed:

(5)

(5)

Conclusion

This mathematical model describes the

static and dynamic characteristics of the process in a fluidized bed

granulation and shows the change in coolant temperature and fluidized bed

during the heat-mass transfer processes in moving granular material through

appropriate technological zone in the apparatus, which providing granular

product with the desired properties.

The variation of

temperature determines the granulation kinetics and physical and mechanical

properties of the pellets. Therefore, the proposed mathematical model can be

used to create an effective system of control the process of formation of

mineral fertilizers in the fluidized bed with liquid dehydration systems.

Bibliography

1.

Korniyenko B.Y. Features modeling of transport processes in disperse systems / B.Y. Korniyenko // Journal

of the National Technical University of Ukraine "Kyiv Polytechnic

Institute" series "Chemical engineering, ecology and resource

conservation". – 2011, ¹ 2(8). - P. 5-9.

2.

Korniyenko B.Y. The dynamics of the processes of dehydration and

granulation in fluidized bed / B.Y. Korniyenko // Journal of the National Technical

University of Ukraine "Kyiv Polytechnic Institute" series

"Chemical engineering, ecology and resource conservation". – 2012, ¹

1(9). - P. 15-19.