Natalia Melnyk

Kyiv State Maritime Academy

WORLD

SHIPBUILDING

Shipbuilding is the construction of ships and floating vessels. It

normally takes place in a specialized facility known as a shipyard.

Shipbuilders, also called shipwrights, follow a specialized occupation that

traces its roots to before recorded history.

Shipbuilding and ship repairs, both commercial and military, are

referred to as "naval engineering". The construction of boats is a

similar activity called boat building.

Shipbuilding is an important and strategic industry in a number of EU

Member States. Shipyards often play a significant role for the regional

industrial infrastructure and, with regard to military shipbuilding, for

national security interests. The European shipbuilding industry is the global

leader in the construction of complex vessels such as cruise ships, ferries,

mega-yachts and dredgers. It also has a strong position in the building of

submarines and other naval vessels. Equally, the European marine equipment

industry is world leader for a wide range of products from propulsion systems,

large diesel engines, environmental and safety systems to cargo handling and

electronics.

There are around 150 large shipyards in Europe, with around 40 of them

active in the global market for large sea-going commercial vessels. Around

120,000 people are directly employed by shipyards (civil and naval, new

building and repair) in the European Union. With a market share of around 15%

in volume terms, Europe is still vying (with South Korea) for global leadership

in terms of the value of civilian ships produced (18 billion Euros in 2011)[1].

But today's leaders in global shipbuilding is Korea, China and Japan

South Korea is

the world's largest shipbuilding nation with a global market share of 37.45% in

2011. South Korea is the global leader in the production of advanced high-tech

vessels such as cruise liners, super tankers, LNG carriers, drill ships, and

large-sized container ships. In the 3rd quarter of 2011, South Korea won all 18

orders for LNG carriers, 3 out of 5 drill ships and 5 out of 7 large-sized

container ships[2].

South Korea's

shipyards are highly efficient, with the world's largest shipyard in Ulsan

operated by Hyundai Heavy Industries slipping a newly-built, $80 million vessel

into the water every four working days [3]. South Korea's "big

three" shipbuilders, Hyundai Heavy Industries, Samsung Heavy Industries,

and Daewoo Shipbuilding & Marine Engineering, dominate global shipbuilding,

with STX Shipbuilding, Hyundai Samho Heavy Industries, Hanjin Heavy Industries,

and Sungdong Shipbuilding & Marine Engineering also ranking among the top

ten shipbuilders in the world[4]. In 2007, STX Shipbuilding further

strengthened South Korea's leading position in the industry by acquiring Aker

Yards, the largest shipbuilding group in Europe. (The former Aker Yards was

renamed STX Europe in 2008). In the first half of 2011, South Korean

shipbuilders won new orders to build 25 LNG carriers, out of the total 29

orders placed worldwide during the period[4].

China is an

emerging shipbuilder that briefly overtook South Korea during the 2008-2010

global financial crisis as they won new orders for medium and small-sized

container ships based on their cheap prices, although its current production is

limited mainly to basic vessels [2].

Japan lost its once industry leading position to South Korea in 2003,[3]

and its market share has since fallen sharply. The European nations' combined

output has fallen to a tenth of South Korea's, and the outputs of the United

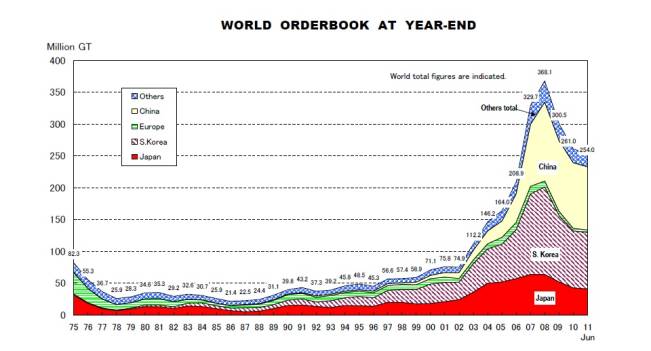

States and the rest of the world have become negligible.[4]World shipbuilding orderbook

at Year-end share by countries (2011)[2].

Japan lost its once industry leading position to South Korea in 2003,[3]

and its market share has since fallen sharply. The European nations' combined

output has fallen to a tenth of South Korea's, and the outputs of the United

States and the rest of the world have become negligible.[4]World shipbuilding orderbook

at Year-end share by countries (2011)[2].

Modern

shipbuilding makes considerable use of prefabricated sections. Entire

multi-deck segments of the hull or superstructure will be built elsewhere in

the yard, transported to the building dock or slipway, then lifted into place.

This is known as "block construction". The most modern shipyards

pre-install equipment, pipes, electrical cables, and any other components

within the blocks, to minimize the effort needed to assemble or install

components deep within the hull once it is welded together.

Ship design work,

also called naval architecture, may be conducted using a ship model basin.

Modern ships, since roughly 1940, have been produced almost exclusively of

welded steel. Early welded steel ships used steels with inadequate fracture

toughness, which resulted in some ships suffering catastrophic brittle fracture

structural cracks (see problems of the Liberty ship). Since roughly 1950,

specialized steels such as ABS Steels with good properties for ship

construction have been used. Although it is commonly accepted that modern steel

has eliminated brittle fracture in ships, some controversy still exists [5].

Brittle fracture of modern vessels continues to occur from time to time because

grade A and grade B steel of unknown toughness or fracture appearance

transition temperature (FATT) in ships' side shells can be less than adequate

for all ambient conditions[5].

References

1.

European Commission Enterprise and

Industry http://ec.europa.eu/enterprise/sectors/maritime/shipbuilding/index_en.htm

2.

Korean: Korea Marine, # 1 four years

recaptured http://news.khan.co.kr/kh_news/khan_art_view.html?artid=201110192122065&code=920501

3.

James Brooke (2005-01096).

"Korea reigns in shipbuilding, for now". The New York Times.

Retrieved 30 December 2009.

4.

"7 Korean Shipbuilders Rank in

Top 10". Marinetalk.com. 2006-01-03. Retrieved 2010-11-17.

5.

"Marine Investigation Report -

Hull Fracture Bulk Carrier Lake Carling". Transportation Safety Board of

Canada. 19 March 2002. Retrieved 8 October 2009.