UDC

538.9:621.785.6

Mukazhanov Ye.B.1

Telebayev Ye.Ye.2

Takenova G.D.3

Tynaliev Bauyrzhan4

1 Doctoral

Student, PhD, Associate Professor, Academy of Economics and Law, Zhetysu State

University. I.Zhansugurov, Taldykorgan, Kazakhstan

Taldykorgan

Polytechnic College

2 Taldykorgan

Polytechnic College

3 PhD, Associate Professor, Taldykorgan Polytechnic College

4 Taldykorgan

Polytechnic College

Taldykorgan,

Kazakhstan

INFLUENCE OF DIFFERENT

MODES TEMPERING ON MECHANICAL PROPERTIES SPRING CR-NI ALLOY

Introduction

Dispersionhardening chromium-nickel

alloy 47HNM has high corrosion resistance, low temperature coefficient of the

modulus of elasticity nonmagnetic, low hysteresis and elastic springback, high

fatigue strength and is used in the industry, not only as a structural

material, but also as a spring alloy. For processing the alloy 47HNM recommended

modes: hardening of 1250ºC, aging at 700 - 725 ºC, 5H [1]. It is

known [1, 2], the technological properties of the alloys depends on the

heat-treatment. Therefore, for the selection of optimal processing conditions

should be aware of the dependence of the mechanical properties of the alloy

hardening behavior in a wide temperature and time interval. However, analysis

of the literature showed that almost no information about the mechanical

properties of the alloy 47HNM depending on hardening behavior and

evidence-based explanations for these changes.

Based on the foregoing, in the

objective was to investigate the influence of quenching temperature and

exposure time for hardening on the technological properties of the alloy 47HNM.

Experiment

47HNM hardened alloy samples was

carried out in water after heating at different temperatures 950-1300ºC.

Heating for quenching was carried out in a salt bath of molten BaCl2,

as well as inert gas.

Mechanical testing of samples at

room temperature uniaxial tensile carried out on the construction L.I.Vasileva

type "POLIYANI" standard procedure. The diagrams were calculated

tensile yield strength and durability, as well as determine the elongation of

the samples after the break.

Results and Discussion

Effect of quenching temperature on

the technological properties of the alloy 47HNM consider the range 950-1300

º C, because below 950 º C intermittent decay begins to develop with

the release of α-phase, and above 1300 º C is observed burnout

material.

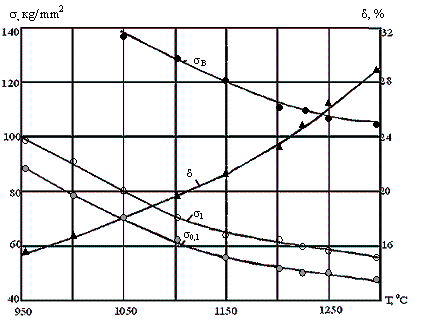

Figure 1 shows the dependence of

ductility and resistance to deformation of the alloy 47HNM temperature

quenching. The analysis of the dependence can be seen that as the quenching

temperature ductility of the alloy is increased, and the flow stress (σ0,

1 - yield stress, σ1 - voltage residual strain of 1%, σV - strength)

decrease. Increase in ductility with temperature hardening due not only to the

dissolution, but also the processes of coalescence and sferoidezatsii excess

α-phase.

Thus, with increasing quenching

temperature increases the homogeneity of the solid solution, as the

concentration and reduction (healing) defects of the building. It should be

noted that a further increase in temperature over 1300 º C leads to a

sharp drop in plasticity. The reason for this phenomenon is caused not only by

grain growth and the formation of assorted, but fusion α-particle phase

near the grain boundaries and the spreading of the liquid phase at the grain

boundaries. It is likely that the fused areas there is penetration of

components of the furnace atmosphere, leading to the formation of oxides,

nitrides or gas bubbles, while it is possible that this may also be the cause

embrittlement of the alloy. Therefore, in order to avoid burnout material

heating temperature should not exceed 1275 º C.

Figure 1 Dependence of ductility and

resistance to deformation of the alloy 47HNM quenching temperature

As

the temperature hardening the plastic properties of the alloy decreases,

suggesting incomplete dissolution of excess α-phase, and at 950 º C

elongation samples to divide half that at high temperature - 1300 º C, at

the same time there is a growth of the deforming stress (Fig. 1).]

Consider

the change in the technological properties of the alloy on the duration of

exposure 47HNM heating temperature before quenching. The studies were conducted

in the temperature range 1100-1300 º C, at the same time under quenching

is from 1 to 30 minutes. Nature of the change of plasticity and deforming

stresses, depending on the length of time before quenching is shown in Fig. 2 -

4.

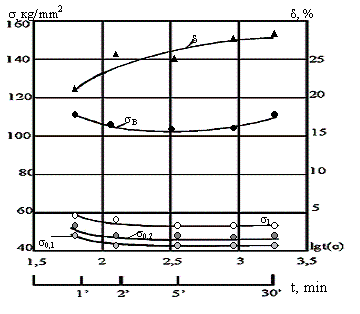

Analysis

of the relationship of technological properties of the holding time at 1300

º C (Fig. 2) and 1250 º C (Fig. 3a) shows that with increasing

duration of heat flow stress drops, there is a growth of plasticity. Decrease

the resistance to deformation, and increased plasticity involves the

dissolution of excess α-phase based on Cr, which has a bcc lattice (Fig.

4). The process starts with the dissolution of dispersed particles, and with

increasing exposure time begin to dissolve and larger particles, enriching

alloying component solid solution matrix. Growth plasticity with increasing

time of homogenization at 1300 º C is up to 30 minutes, inclusive, after

which the curve reaches saturation.

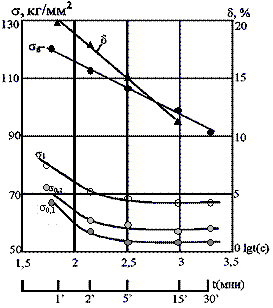

Figure 2. The dependence of the

technological properties (ductility and resistance to deformation δ

σ) alloy 47HNM the time of exposure at 1300 º C

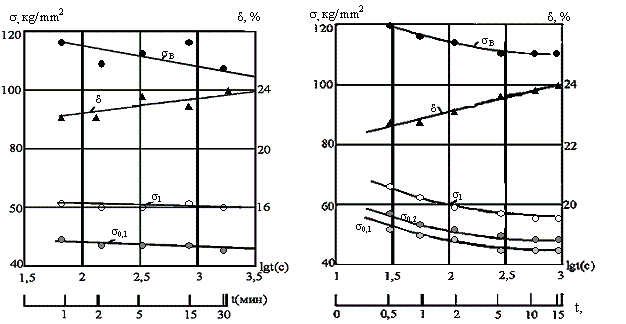

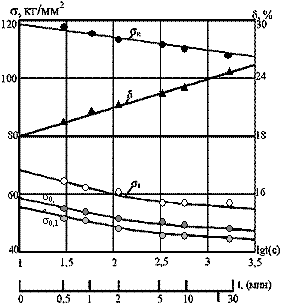

The

nature of technological change in the properties as a function of exposure time

at 1250 º C and 1225 º C (Fig. 3a, b) subject to the same laws as at

1300 º C, but occurs at a lower intensity.

a)

b)

Figure 3 Dependence of technological

properties (ductility and resistance to deformation δ σ) alloy 47HNM

the exposure time of a - at 1250 º C; b - at 1225 º C

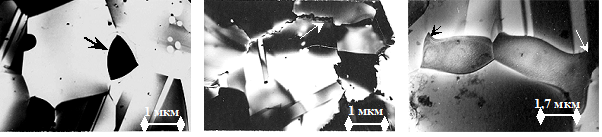

à) b) c)

Figure

4 47HNM microstructure of quenched

from 1250 º C: and -1 min, b - 5 min, c - 10 min.

It is interesting to consider the dependence of the technological

properties of the alloy from the holding time at a temperature of 1200 º C

(Fig. 5a). The presented data show that with increasing time of homogenization

of the alloy mechanical properties fall, but to a much lesser extent, with the

yield strength and tensile strength increased by more than 10 kg/mm2 compared to

the temperature range 1300-1250 º C.

a) b)

Figure 5 The dependence of the

technological properties (ductility and resistance to deformation δ σ) alloy 47HNM the time of exposure: a - at 1200

º C; b - at 1250 º C, the pre-treated at 1100 º C, 5 hours

Nature

of the change of plasticity changes dramatically, the expected growth of

plasticity with increasing heating time observed her fall. The reason for this

phenomenon has not been established, although the nature of the structural

studies of fracture patterns in cross-section show the presence of the

so-called structure of the "slate" kink. It is considered that the

"slate" of the structure is not a marriage of heat treatment, but it

is possible that this may be one of the reasons why the ductility and toughness

of the alloy.

Creation

of a "slate" of the structure of fracture, apparently, could be due

to non-uniform distribution of particles α-phase (Stroke) that the

homogenization of the alloy leads to the dissolution of most of dispersed

particles to form microvoids. Eliminate the "slate" can be prolonged

homogenization of the alloy, but it is necessary to monitor the oven

temperature to avoid burnout.

Should

point to a rather large variations in the ductility and strength testing

samples quenched from 1200 º C. Apparently, the spread of values affects not only the heterogeneity structure,

but also the partial melting of the α-phase particles located at the grain

boundaries and the presence of non-dissolving particles, which are stress

concentrators. All these factors lead to the formation of micro-cracks,

reducing the ductility and toughness of the alloy.

Conclusions

Thus,

hardening alloy 47HNM spending below 1225 º C is not advisable, as it is

the deformation leads to the formation of micro-cracks, reducing the ductility

and toughness of the alloy.

With

the increase of quenching temperature increases homogeneity of the solid

solution, as the concentration and reduction defects of the building. The

increase in temperature over 1300 º C leads to a sharp drop in ductility,

melting due to α-phase particles on the basis of Cr and a spreading of the

liquid phase at the grain boundaries.

With

the increase of the heating time for hardening flow stress drops, there is a

growth of plasticity, which is associated with the dissolution of excess

α-phase. In samples quenched from 1200 º C, the variation of

plasticity changes dramatically, the expected growth of plasticity with

increasing heating time observed her fall. It is assumed that this is caused by

the presence in the structure of the "slate" kink.

literature

1 Molotilov BM Precision alloys. - Moscow,

Metallurgy, 1974. - 448.

2 Erbolatuly D. Features of formation of fine

structures and their influence on the superplastic properties of alloys and

40HNYU 67KN5B / / Proceedings of the Intern. Research School conference.

"Physics and chemistry of nanomaterials." - Tomsk, 2005. - P.52-55.

INFLUENCE OF DIFFERENT MODES TEMPERING ON MECHANICAL PROPERTIES SPRING

CR-NI ALLOY

The

nature of technological change and the strength of the alloy 47HNM by quenching

in a wide temperature and time interval. Shown to increase the hardening

temperature of the alloy up to 1300 º C reduces the mechanical properties

and improved ductility. Found that above 1300 º C ductility decreases

sharply, due not only to grain growth and the formation of assorted, but fusion

α-particle phase based on Cr and a spreading of the liquid phase at the

grain boundaries. With the increase of the heating time for hardening flow

stress drops, there is a growth of plasticity, which is associated with the

dissolution of excess α-phase.