Docent Vlasova

I, Kuryanov K.

Donetsk National University of Economics and Trade named after

M. Tugan-Baranovsky

Fabrication of nonmetallic

PTCs

For nonmetallic and nonmagnetic pulse tube

coolers, besides using nylon mesh, it is of great importance to avoid the

presence of metals in all components of the cold finger. These components

include vacuum chamber, pulse tube, regenerator tube, connecting flanges as

well as heat exchangers.

The tubes of pulse tube and regenerator are the

most important, because of the combined requirements of considerable tensile

strength, and of a fine structure in texture in order to minimize the diffusion

of high-pressure helium gas. This is a really critical demand for nonmetallic

materials due to their intrinsic molecular structures. In the present research,

the regenerator tube is made of a special glassfilled epoxy resin. The

mechanical properties of this material were also tested. A typical cylinder

fabricated by the special glassfilled epoxy resin with a wall thickness of 2 mm,

and 4.5 MPa of helium filling pressure shows the same diffusion of helium

as one made of stainless steel. For the coaxial configuration of the PTC, the

requirements for the pulse tube can be quite easily fulfilled, since there is

only a small load on the tube walls; both Nylon1010 and Teflon are suitable for

the pulse tube.

For the hot end and cold end flange, we have

used a special ceramic, which is non-magnetic, and electrically insulating. Its

mechanical properties and the diffusion of helium through the wall meet the

requirements of long-term operation. Moreover, it is easily machinable and can

be fabricated into the required complicated shapes. The flange at the hot end

is incorporated into the system and serves as hot heat exchanger.

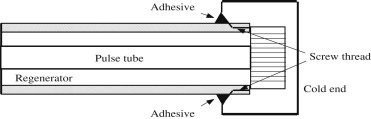

The connection of tubes to both the cold end and

the flange at the hot end are realized by a special synthetic epoxy resin

adhesive, Cryo-3 Glue. The adhesive can be used at a temperature region between

4 and 333 K for various metallic and non-metallic materials with different

expansion coefficients. The lower the temperature, the higher is the adhesive

strength. During the experiments, no diffusion of helium through the

connections into the vacuum chamber was observed. For the cold end connection,

a screw thread is used to enhance the strength, as shown in Fig.1.

Fig. 1. The structure at the cold end.

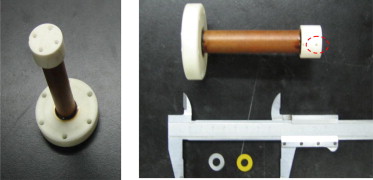

The completely nonmetallic pulse tube cryocooler

is fabricated as illustrated in Fig. 2.

Fig. 2. Photo of cold head with Cryo-3 Glue connection.

Experimental result of nonmetallic PTC

Experiments have been performed by use of a

Leybold Polar SC7 linear compressor with charge pressures of 2.0–3.0 MPa.

The hot end of the PTC is cooled by a fan, which is very simple and convenient,

making the cooling system superior in contrast to the work of the former. The

proper phase shift between mass flow and pressure is accomplished by means of

double-inlet in combination with an inertance tube. As with the metallic PTC,

the volume of the buffer tank is 750 cm3. There is a hole in

the cold with a diameter of 1.6 mm and a length of 15 mm, where the

Pt-100 temperature sensor was located. The resistance of the Pt-100 is measured

by a four wire method.

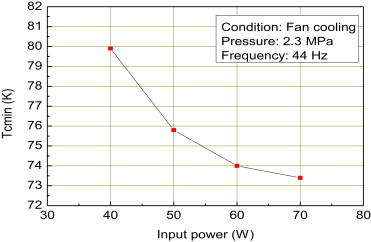

Fig. 3 shows the typical variation of

the lowest temperature Tcmin with compressor input power. Tcmin changes only a

little when the input power is higher than 60 W, since then the hot end of

the PTC is already quite hot. With the compressor efficiency of about 60%, the

Joule heat loss in the ceramic at hot end of the pulse tube has a significant

effect on the cooling performance. The hotter warm end of the non-metallic cold

head compared to the metallic cold head, is a result of the low heat

conductance of the ceramic parts. In former studies of a nonmetallic, water

cooling of the hot end was used to minimize this effect, since otherwise the

minimum temperature increased by about 10 K. Therefore, a compressor with

higher efficiency, which means less Joule heat loss, would be better for this

kind of nonmetallic cooler.

Fig. 3. No-load temperature versus input power for the nonmetallic PTC.

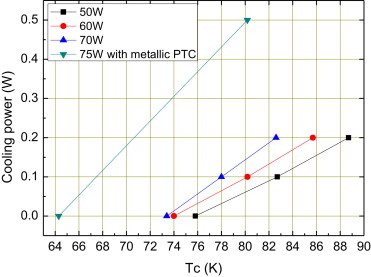

The cooling capacity for this nonmetallic PTC is

displayed in Fig. 4. With

60 W input, we obtain a cooling power of 0.1 W at 80 K, while it

is 0.14 W at 80 K with 70 W input. The slope of the load line is

about 0.022 W K−1 at 70 W input. For

comparison, the cooling capacity of the metallic PTC with nylon mesh has much

larger slope of about 0.033 W K−1 at 75 W

input, as shown in Fig. 4. This means that the poor heat conduction of the ceramic parts at the cold

end has a negative effect with respect to the cooling capacity.

Fig. 4. Cooling power of the nonmetallic PTC versus refrigeration

temperature at different input power.

The above experiments show that the nonmetallic

PTC can operate well at 80 K. Certainly, for higher cooling requirements,

the performance should be further improved.

Conclusions

This work is a further investigation on a

nonmetallic and nonmagnetic pulse tube cryocooler. Theoretical analysis shows

that nylon mesh as regenerator matrix should be as suitable as stainless steel

mesh. However, the experiments by use of a metallic PTC show that the

performance of with nylon matrix is much worse compared with that employing a

stainless steel matrix. The high flow friction factor of the Nylon mesh can be

one of the important reasons for this finding. Another important reason is the

shrinking of the nylon mesh upon cooling which deteriorate refrigeration a lot,

although it can be suppressed partially. Nevertheless, the metallic PTC with

nylon mesh achieved a no-load temperature below 60 K. The completely

nonmetallic coaxial PTC was fabricated by use of a regenerator tube consisting

of glassfilled epoxy resin, a pulse tube consisting of Teflon, the cold end and

hot end flange made of ceramic material, and heat exchangers from nylon mesh.

At 70 W input power, a lowest temperature of 74 K and a cooling

capacity of 0.14 W at 80 K have been achieved. The present job make

an obvious progress in contrast to the former investigation, where the no-load

temperature is 76.8 K. The cooling condition is also simplified

dramatically, replacing the former extremely strict 5 °C water cooling by

the simple fan cooling.

Although this nonmetallic PTC can work at

temperatures near 80 K, the performance is considerably degraded compared

with that of the metallic PTC version. Besides the nonmetallic regenerator

matrix, there are still many problems with the nonmetallic PTC that must be

solved. With further improvements, a nonmetallic PTC with the present

configuration can be an alternative candidate for SQUID cooling.