Potakhov D. A.

Petersburg State Transport University, Russia

Cutting temperature as optimization criterion of the

recovery of railway wheel sets

Usage of new grades of steel wheels with improved physical and

mechanical properties in accordance with GOST 10781-2011 has a certain effect

on the productivity in the recovery of profile of the running surface of wheel

sets of rolling stock. Lack of data on the workability of new grades of steel

wheels makes it difficult to assign rational modes for turning of wheel sets.

The studies are conducted to determine the workability of new grades of steel

wheels and recommendations on the choice of rational modes of recovery of

wheels with increased hardness.

To restore the profile of the running surface of the wheel there is a

wide variety of machine tools with a variety of technical and operational

characteristics that affect the processing time of one single-piece wheel set,

which in turn includes the engine, preparatory and auxiliary time. Analysis of

the process of recovery of profile of

the running surface of the wheel pairs [1] shows that the main reason for

stopping treatment process and, as a consequence, increase the machine time for

the restoration of a wheelset, is the premature failure of the cutting tool. The

life of the tool is significantly affected by the state of the surface of

riding profile, namely, the presence of not only the work surface defects such

as melts, slides and defects with thermomechanical origin, which significantly

increase the hardness of the metal surface layer, but also the variation of the

hardness of the running surface, defined by GOST for each particular brand of

wheel steel.

The science of cutting materials established the existence of the

so-called optimal cutting temperature θ0,

with is a definite value for a particular pair of "instrumental material -

the material being processed." The work on this optimal temperature

ensures the greatest dimension stability for the tool, and the highest accuracy

and the favorable properties of the metal of the surface soil for a processed

detail. [2]

Based on the above the expediency of turning the roll surface profile of

wheelset with an optimum temperature can be concluded, which will reduce the

effect of the state of profile of riding surface during tool life, will give

the finished surface the required accuracy and quality, and will improve the

process of turning the wheel by increasing the efficiency of cutting tools.

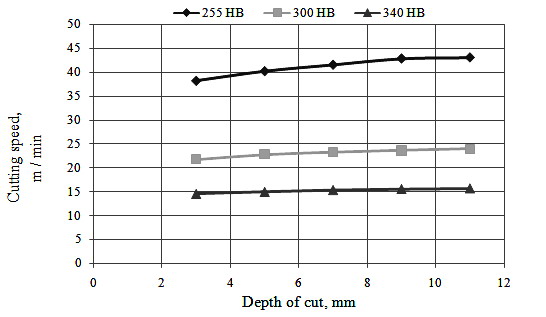

Based on the thermophysical analysis of the recovery of riding surface

of wheelsets of different hardness based on the recommendations [3], it was

found that the effect of depth of cutting on the temperature for a single grade

of steel is negligible. Moreover, with the increasing depth of the cutting

temperature decreases slightly. For example, for steel with a hardness of 255 HB at cutting speed v = 20 m / min and feed s

= 1,1 mm / rev temperature at a depth of cut t = 3 mm be θ = 770 ºC, with a depth of t = 5 mm – θ =766 ºC, and at a depth t = 7 mm – θ = 763 ºC. Were obtained depending on the influence of

graphical wheel hardness steel cutting speed at different depths (Fig. 1),

provided that the optimal cutting temperature, which for the pair of

"wheel – cutting instrument" was taken to be 870 ºC [4].

Fig. 1 The effect of hardness of steel wheel on a

rational cutting speed when

s = 1,1 mm / rev, γ

= 0º

As can be seen from Fig. 1 for the effective recovery of wheelsets with

increased hardness made of steels of grades T and A, GOST 10791-2011, repair

shops will need to reduce the cutting modes of about 2 times compared to the

processing modes for conventional rail wheels of grades 1 and 2 according to

GOST 10791-2011.

References:

1. Bogdanov A. F. i dr. Vosstanovleniye profilya poverkhnosti kataniya

kolesnykh par: Uchebnoye posobiye / A. F. Bogdanov, I. A. Ivanov, M. Sitazh. –

SPb.: PGUPS, 2000. – p. 128.

2. Makarov A. D. Optimizatsiya protsessov rezaniya. – M.:

Mashinostroyeniye, 1976. – p. 278.

3. Reznikov A. N. Teplofizika protsessov mekhanicheskoy obrabotki. – M.:

Mashinostroyeniye, 1981. – p. 279.

4. Vorobiev A. A. i dr. Resurs i remontoprigodnost kolesnykh par

podvizhnogo sostava zheleznykh dorog. Monografiya / Pod red. prof. I. A.

Ivanova. – M.: INFRA-M, 2011. – p. 264. – (Nauchnaya mysl).