Dr. Sc. Vitrenko

V.A.

Postgraduate

Kashura M.A.

East Ukrainian

National University V. Dahl

Simulation of temperature processes in the

interaction gear teeth with teeth screw hyperboloid lap

Introduction. Modern manufacturing process gear

manufacturer must provide details of relevant operating conditions and accuracy

requirements at minimum cost. The main factors affecting the choice of the

process are: the design and size of gear; procurement type and material,

requirements for accuracy and heat treated wheels and the volume of

production. The proper assignment of the cutting for machining has a big

impact on the quality of the machined surface.

One of the parameters that accompany the process

of treatment and affects quality is the temperature that occurs between the

surface of the treated parts and tools. The high temperature exposure can

lead to the burn marks, deformation work surface, micro-cracking, etc.

Contact temperature is of interest to study, because influence

the quality of the treated surface [12].

The purpose of the article. Construct a mathematical

model and calculate the temperature encountered in the processing of the tooth

spur gear screw hyperboloidal lap.

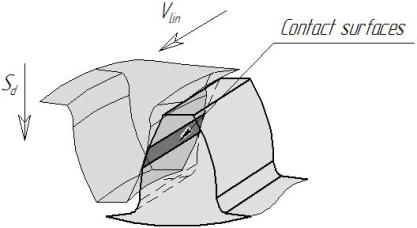

The main part. Consider the circuit grinding gear teeth

helical hyperboloid lap as the transfer to the crossed axes, where the lap

rotates on its axis and performs translational motion with supply S, the gear

rotates around the axis (Fig. 1). The equation of the relative sliding

velocity can be written as follows:

(1)

(1)

Fig. 1. Diagram of teeth grinding spur

gear screw hyperboloid lap.

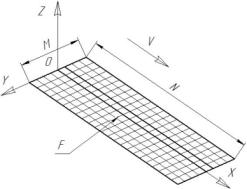

To determine the contact cutting temperature

should consider the example of the interaction of the surface of the tooth with

the gear tooth surface tool (lap pressed to the wheel with the force of the

treated S d and rotate with a certain angular velocity ω, the relative

sliding velocity V lin) (Fig. 2).

Fig. 2. Scheme contact surfaces

treated tooth and the tooth wheel of lap

Under the force of Sd, by the

elasticity of the materials and tools produced wheel contact patch, which has a

rectangular shape. The image size of the contact area of the surface of

lap and gear can be determined by the formulas of the theory of elasticity [9].

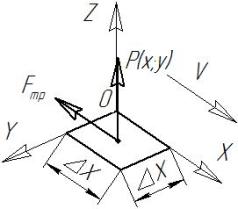

Contact pattern (area F) can be represented as a

set of rods with insulated side walls (Fig. 3).

|

Fig. 3. The scheme of the contact. |

Fig. 4. Scheme at the direction of the

forces. |

At each point of the contact forces are

presented in Fig. 4, which ![]() is the force of friction -

friction

is the force of friction -

friction ![]() - normal load acting,

- normal load acting, ![]() at the center of each cell and the contact is defined as the product of

voltage in each cell of the contact in their area.

at the center of each cell and the contact is defined as the product of

voltage in each cell of the contact in their area.

To determine the voltage ![]() at each point of contact area used

formula by Hertz.

at each point of contact area used

formula by Hertz.

, (2)

, (2)

where - the maximum voltage in the center of the

contact patch.

In this scheme contact gear screw hyperboloidal

lap, the maximum tension ![]() can be defined by the formula [9]:

can be defined by the formula [9]:

![]() . (3)

. (3)

where ![]() the coefficient, the value of

which is determined by the table [9], page 642.

the coefficient, the value of

which is determined by the table [9], page 642.

The temperature at the surface of the rod,

located in the contact area can be determined by the example of a semi-infinite

body heated by a heat flux of constant power [11]. Temperature distribution

over the thickness of the body at any given time is determined by the formula:

(4)

(4)

in this case the function, hence the expression

(4) will be:

(5)

(5)

where:

![]() -thermal conductivity, c - specific heat, and

-thermal conductivity, c - specific heat, and ![]() the density [12],

the density [12], ![]() the contact time, duration of

exposure to the heat source to the point half - cell length of the contact,

which is equal to the surface grid step along the x-axis (Fig. 4).

the contact time, duration of

exposure to the heat source to the point half - cell length of the contact,

which is equal to the surface grid step along the x-axis (Fig. 4).

![]() - heat flux on the surface of cells of the contact, which can be determined

from:

- heat flux on the surface of cells of the contact, which can be determined

from:

(6)

(6)

where

F - the contact area of the cell;

![]() - the amount of heat that results from the work of friction forces at the

time

- the amount of heat that results from the work of friction forces at the

time ![]() , determined from the expression:

, determined from the expression:

![]() (7)

(7)

where ![]() is the coefficient of heat flux

distribution (assuming equal to 0.5 [14]).

is the coefficient of heat flux

distribution (assuming equal to 0.5 [14]).

![]() - power of friction is determined from (7):

- power of friction is determined from (7):

![]() . (8)

. (8)

In the simulation process, contact temperatures

grinding gear made of steel St35, screw hyperboloid lap made of cast iron GG20,

the calculation is performed in turn for each m-th band of the contact. The

initial temperature distribution along the length of the rod is considered

known and equal to zero, and the power for the time ![]() constant of the heat source. After the calculation of the temperature

at the end of the first to the direction of travel of the rod from the heat

source

constant of the heat source. After the calculation of the temperature

at the end of the first to the direction of travel of the rod from the heat

source ![]() in the course of time

in the course of time ![]() , a transition to the next bar. At the second bar for the same period

of time effective heat source

, a transition to the next bar. At the second bar for the same period

of time effective heat source ![]() (the value of which is determined

as the difference between the temperature-induced source

(the value of which is determined

as the difference between the temperature-induced source ![]() (for the time

(for the time ![]() - passed two bars) and

temperature on the action of the same power source

- passed two bars) and

temperature on the action of the same power source ![]() for the time

for the time ![]() ). Thus calculated the temperature change in the core of the change in

temperature

). Thus calculated the temperature change in the core of the change in

temperature ![]() and additive, which occurred after

the end of the source

and additive, which occurred after

the end of the source ![]() through time

through time ![]() . Thus computations were performed M times, followed by a transition

to the consideration of the next strip contact, examination, which for the

first while moving the rod again take zero initial conditions.

. Thus computations were performed M times, followed by a transition

to the consideration of the next strip contact, examination, which for the

first while moving the rod again take zero initial conditions.

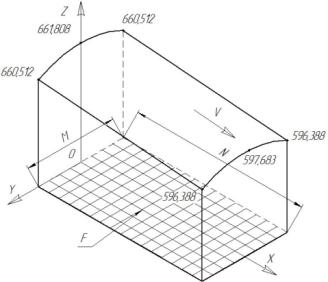

Research results. The calculation by the present model, the

values of temperature (Fig. 5) (relative sliding velocity Vlin =

0.256 m/s, a pressing force P = 100 N).

Temperature occurs on the surface of cells of

the contact gear tooth reaches 661 C.

Fig. 5. The temperature field on the

surface of the contact

Conclusions. Based on the processing method of

teeth spur gears helical hyperboloidal lap the technique of calculating the

temperature in the treatment area, with which you can select the optimal modes

grinding, allows get high precision and avoid burn marks, deformation work

surface and microcracks.

References: 1. Abrasive and diamond material

processing: Directory / [A.N. Reznikov, E.I. Aleksentsev,

M.I. Barat] - Mashinostroenie, 1977. - 391 p.

2. Vitrenko A.V. Finishing and

hardening treatment tooth spur gears / A.V. Vitrenko, I.A. Kirichenko

// Reliability tools and optimization of systems: a collection of research

papers. - Kramatorsk, 2007. - Vyp.21. - S. 202 - 206.

3. Vitrenko O.S. Increasing the

accuracy of the hardening of teeth rolling through the development of

fundamentally new geometry technology:

Dis. Candidate. tech. Science / VNU them. V.Dal,

2010.

4. Lashnev S.I. Shaping and gear parts

blockboards we worm tools / S.I. Lashnev. - Mashinostroenie,

1971. - 215 p.

5. N.I. Kolchin. Methods for

calculating the production and control gear products / N.I. Kolchin,

F.L. Litvin. - L: Mechanical Engineering, 1952. - 269 p.

6. Markeev A.P. Engineering mechanics:

A Textbook for universities. - Moscow: CheRo, 1999 - 572 p.

7. Manufacture of gears: Directory /

[S.N. Kalashnikov, A.S. Kalashnikov, G.I. Kogan and others];

under red. B.A. Thais. - [3rd ed., Rev. and add.]. -

Mashinostroenie, 1990. - 464.

8. Guide to the strength of materials /

G.S. Pisarenko, A.P. Yakovlev, V.V. Matveyev, Ed. G.S.

Pisarenko -2nd ed., Rev. And add. - Kiev: Nauk. Dumka, 1988.-736

p. - ISBN 5-12-000299-4.

9. Goldfarb E.M. Heat engineering

metallurgical processes. - Moscow, Metallurgy, 1967. - 439 p.

10. Calculation and study of friction

during braking / A.V. Chichinadze. -M.: Science, 1967.

11. Sheveleva G.I. The theory of

morphogenesis and contact of moving bodies. Monograph / G.I.

Sheveleva. - Moscow: Stankin, 1999. - 494 p.

12. Basov G.G. / To the calculation of

temperature on the surface of spot of comb of wheel with the lateral surface of

head of rail //, Gorbunov N.I., Popov S.V. IV International congress

"Mechanical engineering technologies` 04. " Sofia. - Year

XI, Volume 8/76, September 2004. - Section 6, p. 133-135.

13. Manufacturing Processes 2. Fritz Klocke,

Aaron Kuchle, RWTH edition Engineering (Springer-11647) Springer, 2009 p. 433.

14. Influence of

surface condition on the fatigue behaviour of specimens made of a SAE 5115

case-hardened steel. S. Laue, H. Bomas., F. Hoffmann. Fatigue & Fracture of

Engineering Materials & Structures. Volume 29, Issue 3, pages 229–241,

March 2006.