Abdraimova Nurila Ondirisovna, Bainiyazova Akmaral

Taskaraevna, Demeuova Akmaral Bahitbekovna

Kyzylorda state university named after Korkyt – Ata

E-mail: Akmabay@mail.ru

Automation and control system tank farm

Abstract

This article

comprises data for Delta V visualization system software to control process

parameters of the Tank farm using operator workstation. This article shall be

used as the operation guide.

This article

describes the visualization systems purpose, its capability and function,

general rules for operation, operator and other engineers guide to realize

various functions.

Introduction

The technology of

process instrumentation continues to grow in both application and sophistication.

The various control equipment components that may be used to regulate a process

and certain aspects of process behavior will be discussed in this article.

Automation consists

in the realization of oil storage plant measuring information control system

and is based on Fisher-Rosemount HTG oil hydrometer, gagging and record system in

tanks. Control system is provided by Delta V full-service distribution system. Field

devices, controllers and workstation operate simultaneously consisting of the

system, provided each management each on its level.

Insulated Ethernet

provides data communication between controllers and workstation is the managing

network of Delta V system.

Main Automation

Solutions

Tank field site

equipped with automation and control system. Two – level hierarchical structural

system controls the process. Process variable measurement, transformation of

physical magnitude in signals transferring to upper level, characteristics

recording, signaling, indication, object positioning, stat using and other

operations are fulfilled at the lower level.

HTG system (Fisher-Rosemount) is used for

commercial records of oil in PBC-7, PBC-8, PBC-11, PBC-12, PBC-13, PBC-14

tanks. HTG system controls oil weight, volume, density, level and temperature. HTG

measurement method is fundamentally differed from other tank hydrometer

methods. HTG provides exceptional exact records providing each tank data.

Material weight-to

measure directly (total error +/- 0.05%)

Material density –

to measure directly(total error +/- 0.11%)

Material

temperature– to measure directly(total error +/- 0.11%)

Material level –

calculation (total error +/- 0.11%)

Material volume –

calculation

Material specific

volume +/- 0.11%

Specific density

Weght=(Pbottom-PTap)*square

Density=![]()

Volume =![]()

Level = ![]()

In addition the

system provides all necessary diagnostic information and full signaling (both

local and remote for each tank), possible leakage signaling, continuous quality

and homogeneity control, allowed load/unload material, field characteristics

read etc. altogether 250 characteristics per tank.

The present system

is fully automatic one (excluding manual operations and need for density

laboratory test), flexible one (has modular construction), open (HART protocol

for communication of all intellectual devices, MODBUS RUT protocol for central

process unit control by means RS-485 interfaces, PC and FIX MMI package)

russified operator interface for Windows NT4.0 communications (factory computer

network) and free format report printing, operative one (every second data

updating), service-able (no problems w. encapsulation and pollution and no need

to be on tank roof), reliable one (lack of moving parts, calibration sensor

technology, all system parts error-free running time more than 50 years),

mountable (not required to stop tank operation, to empty and air a tank, to

take 220V supply for each tank, possibility of daisy chain)

Hydrostatic

pressure sensors heating (lower and middle 12 areas in all) is specified for

operability assurance in oil tanks during winter by means of self-regulating

heating cable Chromatrace. Self-regulating effect lies in the following the

lower oil temperature in fitting pipe the larger heat comes from cable and in

case of rise in temperature cable ,s heat-evolution is decreased. One

area power input is 17 watt. Maker supplies full outfit kit including

termination kit, joints, termination seal and mounting boxes.

«Oil-water» phase

division signaling in oil tanks PBC-7, PBC-8, PBC-11-PBC-14 is carried out by

level sensors «Zircon» maker Sensall, installed at the level more than 60mm –

tank bottom water upper level while tank unloading. Gagging principle is to

gage sensor-level permittivity. Sensor sends active part wet-dry signals and

self-control sensor signals in two-wire circuit 20mA.

Oil overflow upper

level alarm in tanks PBC-7, PBC-8, PBC-11-PBC-14 shall be done by level sensors

«Sapphire» maker Sensall, installed at limit filling level. Gagging principle

is to change propagation of ultrasound between sensor detectors. It sends

active part wet-dry signals and self-control sensor signals in two-wire circuit

4-20mA.

For water level

control in water tanks PBC-9, PBC-10 the following system is provided.

-

in water tank PBC-10 for water overflow level maker Sensall are applied

-

in water tank PBC-9 maker Krohne reflexive action radar oil level sensor

is applied owing to trapped oil

-

PBC-9, PBC-10 water tank temperature control is carried out by thermo

elements with unified output signal and are provided water temperature

measurement. The supplier is Metran product group.

Controller fulfills

all I/O signal pickup logical operations and process management operations in case of need. Fiber optic cable connects

controller with Delta V work station through Ethernet. Field instrumentations

installed on oil and water tanks directly. Delta V system work station

installed in control room.

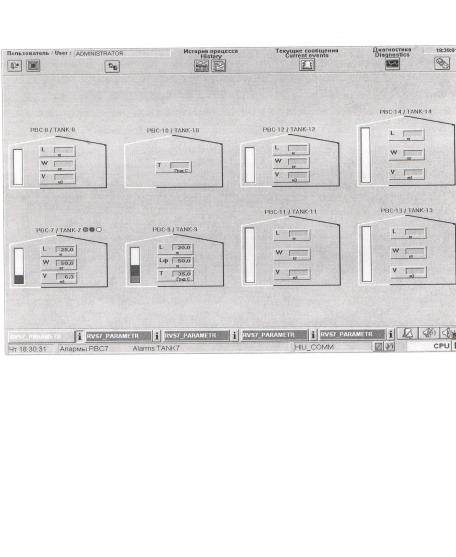

Figure 1. Tank Farm

Instrumentation.

Summary

The

typical process plant contains many tanks, vessels, and reservoirs. Their

function is to store or process materials. Accurate measurement of the contents

of these containers is vital. The material in the tanks is usually liquid, but

occasionally it may consist of solids.

Initially,

level measurement appears to present a simple problem. However, a closer look

soon reveals a variety of problems that must be resolved. The material may be

very corrosive; it

may tend to solidify;

it may tend to vaporize;

it may create other difficulties.

Bibliography

1. Norman A. Anderson. Instrumentation for Process Measurement and

Control. Radnor, PA: Chilton, 1989.

2. Shinskey, F.G. Process control systems. New York:

McGraw-Hill Book Company, 1979.

3. Liptak, B.G.

Instrument Engineers Handbook, vols. I and II. Radnor, PA: Chilton Book

Company, 1970.

4.

Åäèãàðîâ. Ì. Íåôòåáàçû è ãàçîõðàíèëèùà.

5.

Êîðøàê À.À., Øàììàçîâ À.Ì.Îñíîâû íåôòåãàçîâîãî äåëà. Óôà, 2007.