Lavrenko Ia., Babenko A.

National technical

university of Ukraine «Kievsky

politechnical institut», Kiev, Ukraine

The lifetime

research of laboratory centrifuge

To the high-speed

laboratory centrifuge is put forward a number of requirements, the main one is

to provide the necessary lifetime, the second, the guaranteed service life

should be ensured fail-safety and reliability. These requirements are satisfied

by the elements of data structures must not break down during the guaranteed

period of work and safety is guaranteed by the presence of emergency shell [1].

Laboratory

centrifuges are used in medical, biomechanical and in chemical laboratories.

The main tasks of design is to ensure reliability, capacity and ease of use.

Because of the different conditions of operation, the industry supports a wide

range of rotors and adapters for laboratory centrifuges (Fig.1). The rotor (I) of lab centrifuge

|

|

|

Fig. 1. Rotor and cap of lab

centrifuge |

which

rotates is one of the most loaded constructive elements who use at variable

loading is destruction represents danger. The cup (II) with different forms for

beakers (III) fixes on pins and changes the position at speed up and speed

down. During the investigation it was found out that the

destruction takes place cups in place of contact with pins, and through

detachment bottom of the cup [2]. Structural elements, which is the danger of

destruction, is a cup.

In this paper the

cups as one main constructive element is mounted to a laboratory centrifuge

rotor, Figure 1 was

considered. To improve the accuracy of predicting the lifetime

of the machine and, consequently, more accurate selection of the parameters of anti-crash container in order to facilitate their weight. To

predict the lifetime of constructive elements, it is necessary to determine more

accurately their stress-strain state (SSS) and mechanical properties of the

material structure.

The

lifetime of construction can be defined as experimental and simulation course.

Actual testing of the acceleration and braking of centrifuge take a

lot of time and are expensive, so to predict the construction resource the

simulation of stress-strain state (SSS) centrifuges at different types of loads

and complex of experimental studies was carried out. In this case, the dynamic

calculations are performed by FEM [3]. Definition of

the stress-strain state made within the collaborative work NTU "KPI"

and the Institute of Mechanics, Otto-von-Guericke University Magdeburg

(Germany) by means of widespread software package ANSYS [4, 5]. The maximum stresses and deformations which

arose in a cup under the influence of a cup body weight were considered first

of all. Identified three levels of stresses (470 MPa, 490

MPa, 500 MPa), which arise in dangerous points of cups lab centrifuge. To determine the influence of stress concentration the parameter which is called as theoretical

coefficient of stress concentration is used [6,7].

|

|

|

|

|

Fig.2 Cyclic load |

Fig.3 Cyclic creep |

Fig.4 Creep |

To the test used

hydraulic test stand MTS 810 (Fig.5). Mechanical properties of samples were

determined by their stretching with speed of 10 mm/min. Tests made according to GOST 1497-84.

The character of deformation studied on diagram points according to the methods [8].

|

|

|

Fig.5 Samples and test stand MTS 810 to determine the mechanical

properties of materials |

To

the test used hydraulic test stand MTS 810 (Fig.5), through which conducted

three phases of research. In the first phase of research were tested

cylindrical specimens of aluminum alloy 7075 on low cycle (Fig.2) with sawtooth

cycle fatigue loading (loading sample to the required level of stresses

occurred at 5sec and unloading 5sec). In the second phase were tested at

constant load to fracture (Fig.4). Laboratory centrifuges work in different conditions,

therefore the time the centrifuge is in the operating conditions could be

different. In this paper, the time ![]() chosen on the basis

of the optimal time of testing samples. The third phase of testing - the study

sample at program load (Fig.3) (load sample 5sec, holding at constant load

120sec and unloading 5sec).

chosen on the basis

of the optimal time of testing samples. The third phase of testing - the study

sample at program load (Fig.3) (load sample 5sec, holding at constant load

120sec and unloading 5sec).

|

|

|

Fig.6 Specimens failure probability 1% |

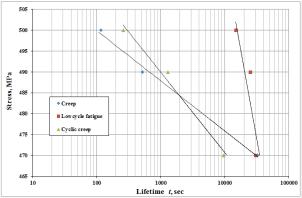

Plot

the fatigue curves was performed by the standard method according to GOST [9, 10].

On the basis of the distribution curves of fatigue life curves of equal

probability was built. At the diagrams curves of fatigue specimens of aluminum

alloy 7075 for the probability of destruction ![]() are shown. Fig. 6

shows the fatigue curves for different types of loading at a probability of 1%.

It can be concluded that the maximum lifetime have specimens that tested at low-cycle

fatigue.

are shown. Fig. 6

shows the fatigue curves for different types of loading at a probability of 1%.

It can be concluded that the maximum lifetime have specimens that tested at low-cycle

fatigue.

Conclusions

Researches

have shown that the unsuccessful choice of manufacturing techniques of

preparation is one of the reasons which promotes destruction in the form of

branch of a bottom of a the cup shell. In all cases the stress-strain state

simulation has shown that the maximum stresses take place in a point of contact

of a pin of a rotor and cups of a laboratory centrifuge. It leads to cup

destruction in a place of contact of a pin and a cup.

As a result of

experimental studies were built durability and fatigue distribution curves for

aluminum alloy 7075. These data allow to conclude a satisfactory correlation of

experimental and theoretical calculations. The approach proposed by Lemaitre

counting of interaction damage under cyclic creep gives satisfactory results,

but requires further research.

References

[1] Lemaitre J.,

Desmorat R. Engineering Damage Mechanics, Springer, 2005, p.380.

[2] Babenko A., Lavrenko Ia., Strackeljan J. Estimation

of a centrifuge rotor strength and analysis of the influence of constructive

and technological parameters. // 10. Magdeburger Maschinenbau-Tage. 27.-29.

September 2011.

[3] Babenko A., Lavrenko Ia. Vyznachennja napruzheno-deformovanogo stanu

chashky laboratornoi centryfugy pid dijeju dynamichnogo navantazhennja. //

Vseukrainskyj shhomisjachnyj naukovo-tehnichnyj i vyrobnychyj zhurnal.

Mashynoznavstvo. – L.: - 2011. - ¹7-8. - s. 7-10.

[4] Lavrenko Ia. I. Do pytannja

pro vyznachennja resursu konstruktyvnyh elementiv pry zminnyh navantazhennjah.

Visnyk NTUU “KPI”, Mashynobuduvannja. - K.: Yzd-vo KYT, 2009 . - ¹. 56.,

s.88-92.

[5] Stolarski

T., Nakasone Y., Yoshimoto S. Engineering Analysis with ANSYS Software, 2006.

[6] Neuber

H and Hann H. Collection of Translations, Mechanics, ¹4, 1967.

[7] Pisarenko G. S. Strength of materials - 5th ed. Rev.

And add. - K.:

Highest sc. Head Press, 1986.

[8] Pavlov I. M.,

Shelest A.E., Tarasevich Y.F. The study of discontinuous deformation patterns of

some alloys after thermomechanical processing. - In Sat: Plastic

deformation of refractory metals and special alloys. Nauka,

Moscow, 1970, p.111-125.

[9] GOST 28785-90

«Ultracentryfugy ta rotory preparatyvni. Zagalni tehnichni vymogy ta metody

vyprobuvan».

[10] GOST 25.502-79 «Metody mehanichnyh vyprobuvan

metaliv. Metody vyprobuvan na vtomu».