UDC 687.053.72.002.54

INNOVATIVE

METHODS FOR DESIGNING AUTOMATED MACHINES

Sabit D. Baubek

Professor, Kunsulu S. Taukbaeva Ph.D.

Taraz innovation and Humanities University (TIÍU), Kazakhstan

The

author proposes a new method and device for its realization [1,2].

The article qives The results of studies of technological capability of

automated machines (ASHM330), where the first needle deflection is involved in guiding the workpiece during sewing.

The purpose of dynamic analysis is to

develop a mathematical model of efficiency ASHM330 providing quality lines.

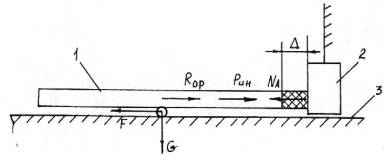

Figure

1 shows the design scheme of the dynamics of the process orentirovaniya

details.

Figure

- 1. Dynamics of orientation details

1-piece,

2-stop 3-desktop machine, a deformation of the edge details of emphasis.

The

deformation of the edge details with ASHM330 not exceed permissible value ![]() , that is, provided

conditions are equidistant lines with respect to the circuit details

, that is, provided

conditions are equidistant lines with respect to the circuit details

![]() , (1)

, (1)

where ![]() - the deformation of

the edge details of the fence.

- the deformation of

the edge details of the fence.

Note

that this is the strain at every step of the stitch in the process of

orientation with ASHM330 makes the part, "recoil" from the stop after

leaving the needle on the material [3]. Since this process is repeated at every

turn, it seems that part varies automatically.

So, for

the determination of the light and dry friction conditions (1), the principle

of D ¢ Alambera, we write the equations of equilibrium of forces acting:

![]() , (2)

, (2)

where F - principal vector of the mass center

of friction, taking into account dry friction; Puí - inertia moving

parts, Puí=m∂ a∂,

, where m∂ - weight,

a∂ - acceleration

details, NÀ - normal pressure parts for

emphasis; ![]() = R

= R![]() cosφ;

cosφ;

![]() - orienting force.

- orienting force.

,

(3)

,

(3)

![]() - reaction to the needle deflecting material during its orientation;

- reaction to the needle deflecting material during its orientation;

![]() - the pressure of the

transporting roller to the material;

- the pressure of the

transporting roller to the material;

![]() - drag coefficient between the rollers and the material;

- drag coefficient between the rollers and the material;

![]() - the distance from the needle and roller until it stops;

- the distance from the needle and roller until it stops;

![]() - location of stops.

- location of stops.

A Coulomb drag force between the material and

the surface of a platform machine is determined by the formula

![]()

, (4)

, (4)

here, ![]() , Q=Nc - the pressure of an additional rail on the

workpiece;

, Q=Nc - the pressure of an additional rail on the

workpiece;

ê=f - coefficient of friction parts of the needle

plate;

Ψ - angle of

rotation of the orienting parts in the sewing process;

r1, r2 - radius vector joining the origin of the system and the element

ds;

υ -

velocity components;

ω -

angular velocity of the details in its orientation;

g - acceleration of gravity is the details;

![]() - radius of the stop.

- radius of the stop.

ð - density distribution function details.

But inertia is defined as, where - the center of mass acceleration

details.

+

+![]() ; (5)

; (5)

Conclusions: Studying (3 and

5) on a computer can determine the optimal

parameters of the new device

as ω , ψ, ![]() ,

, ![]() ,

, ![]() , which were used to develop

ASHM330. Here are the results of studies of the dependence R

, which were used to develop

ASHM330. Here are the results of studies of the dependence R![]() (

(![]() ) and

) and ![]() (

(![]() ) using the program Maple 6, the graphs show (Fig. 2), which

decreases with increasing:

) using the program Maple 6, the graphs show (Fig. 2), which

decreases with increasing:

![]() Rîð

Rîð

Figure

2.Issledovanie-based R![]() (

(![]() ). Figure 3. esearch depending Rîð (

). Figure 3. esearch depending Rîð (![]() ).

).

Used literature

[1] Baubek SD, Taukebaeva

KS, Kazahbaev SZ. Device for contouring

products of light industry. (Patent number 23,217 on RK 15/11/2010. NIP RK., Publ. from

27.04.2010, Almaty. Bull. ¹ 12. – 4)

[2] Baubek SD, Taukebaeva

KS, Kazahbaev SZ.

Method prinudidelnoy assembly of workpieces contouring (Patent number 23,216 on RK

15/11/2010. NIP RK., Publ. from 27.04.2010, Almaty. Bull. ¹ 12. - 4:)

[3] Baubek SD. Basics of

friction-orienting devices for automated contouring of parts. Textbook. Taraz: Typography NICE, 2009 .

The summary

The results of studies of technological

capability of automated machines (ASHM330), where the first needle deflection

involved in guiding the workpiece during sewing. A mathematical model of

efficiency ASHM330 providing quality lines. Optimal parameters of the new

device. The work is funded by a grant from the JSC "Fund Science" by

MES under contract number 9 on 10.12.2010, the

Àííîòàöèÿ

ñòàòüå ïðèâåäåíû ðåçóëüòàòû èññëåäîâàíèÿ

òåõíîëîãè÷åñêîé âîçìîæíîñòè

àâòîìàòèçèðîâàííîé ìàøèíû (ÀØÌ330), ãäå âïåðâûå îòêëîíÿþùàÿ èãëà ó÷àñòâóåò ïðè

îðèåíòèðîâàíèè çàãîòîâêè ïðè øèòüå. Ðàçðàáîòàí ìàòåìàòè÷åñêèé ìîäåëü ðàáîòîñïîñîáíîñòè ÀØÌ330, îáåñïå÷èâàþùàÿ êà÷åñòâà ñòðî÷êè. Ïîëó÷åíû îïòèìàëüíûå ïàðàìåòðû íîâîãî óñòðîéñòâà.

Ðàáîòà ôèíàíñèðóåòñÿ ãðàíòîì ÀÎ «Ôîíä íàóêà» ïðè

ÌÎÍ ÐÊ ïî äîãîâîðó

¹9 îò

10.12.2010 ã.

About author:

Baubek

Dzhumabaevich Sabit, D.Sc., Vice Rector, Taras Humanities - an innovative

university, URL. 080 011, Zhambyl, Taraz, st. Third lane Krasin, 6 / 1, tel.

slave. 8 (7262) 42 - 60 - 26, com. 87,003,246,463.

Taukebaeva

Kunsulu Sathanovna, the applicant, ¹ 53 school, URL. 080 011, Zhambyl, Taraz,

st. Third lane Krasin, 6 / 1, tel. house. 42 - 54 - 82.